MAN B&W 6.04

Page of 12

MAN Diesel

MAN B&W S90MC-C8, K90MC-C6, S80MC-

C8, K80MC-C6, S70MC-C8, S60MC-C8,

L60MC-C7/8, S50MC-C8

198 61 77-6.0

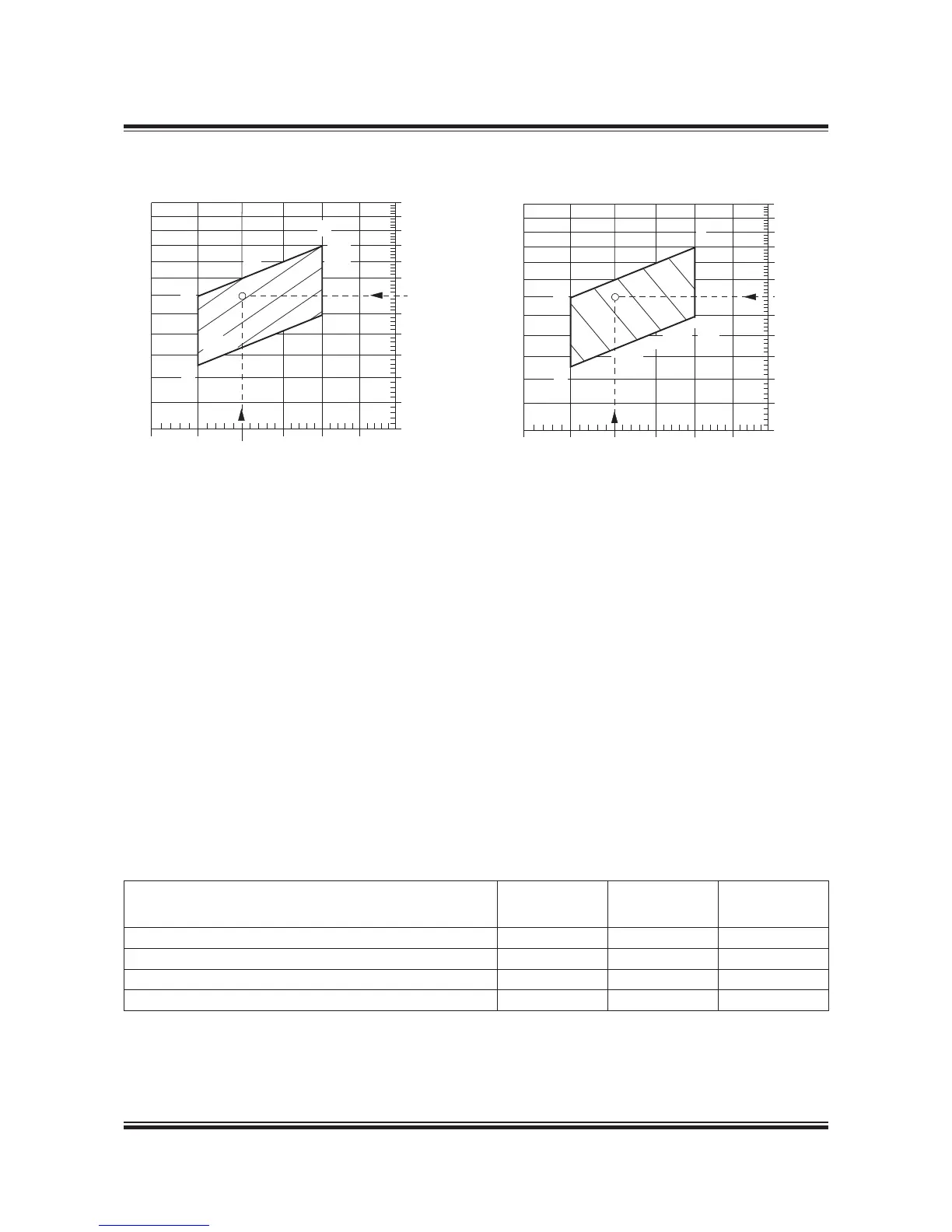

∆m

M%

: change of specic exhaust gas amount, in

% of specic gas amount at nominal MCR

(L

1

), see Fig. 6.04.07.

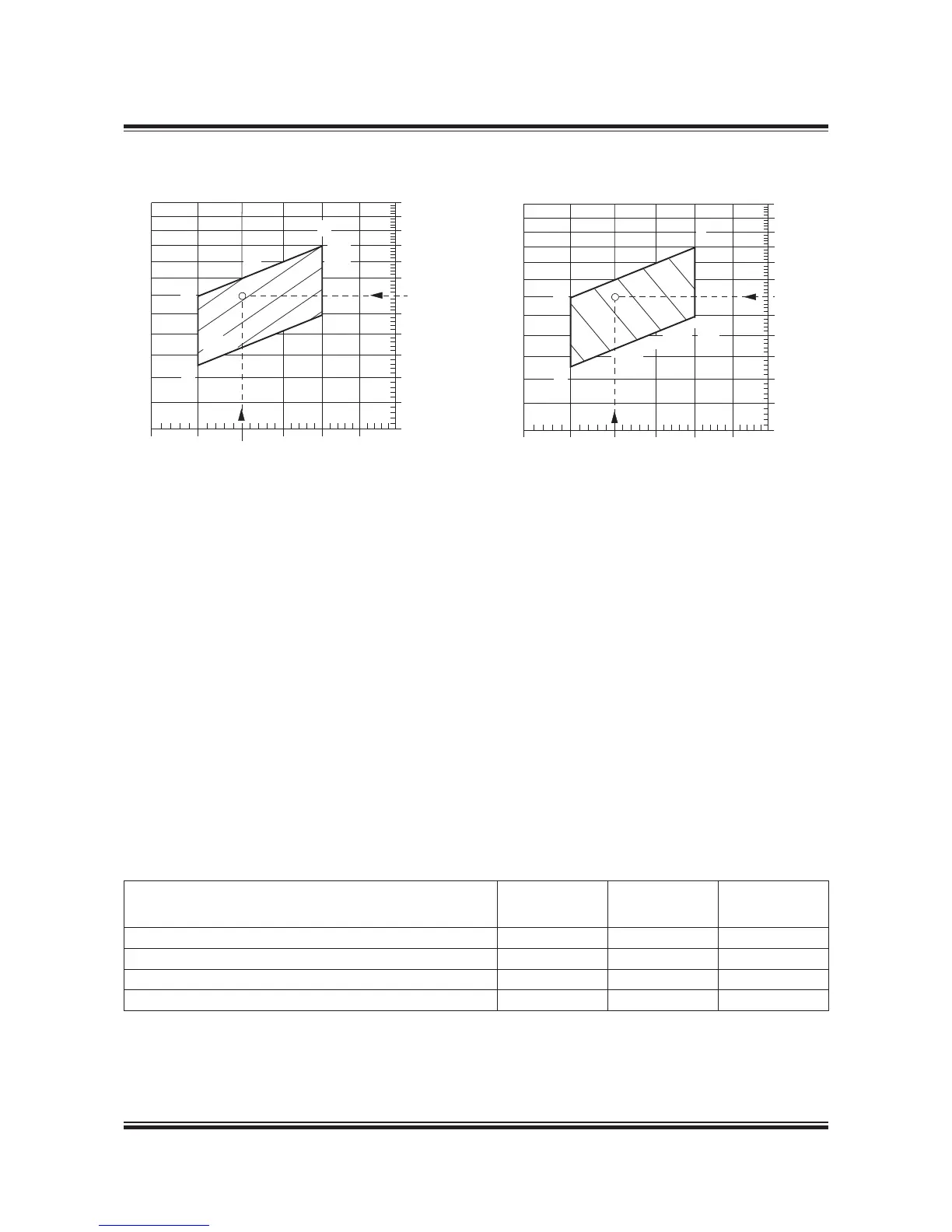

∆T

M

: change in exhaust gas temperature after

turbocharger relative to the L1 value, in °C,

see Fig. 6.04.08. (P

O

= P

M

)

∆T

O

: extra change in exhaust gas temperature

when optimising point O lower than 100% M:

P

O%

= (P

O

/P

M

) x 100%.

∆T

O

= 0.3 x (100 P

O%

) [6]

b) Correction for actual ambient conditions and

backpressure

For ambient conditions other than ISO

3046-1:2002 (E) and ISO 15550:2002 (E), and

backpressure other than 300 mm WC at

specied MCR point (M), the correction fac-

tors stated in the table in Fig. 6.04.0 may

be used as a guide, and the corresponding

relative change in the exhaust gas data may

be found from equations [7] and [8], shown in

Fig. 6.04.10.

Parameter Change

Change of

exhaust gas

temperature

Change of

exhaust gas

amount

Blower inlet temperature + 10° C + 16.0° C 4.1 %

Blower inlet pressure (barometric pressure) + 10 mbar 0.1° C + 0.3 %

Charge air coolant temperature (seawater temperature) + 10° C + 1.0° C + 1. %

Exhaust gas back pressure at the specied MCR point + 100 mm WC + 5.0° C 1.1 %

Fig. 6.04.09: Correction of exhaust gas data for ambient conditions and exhaust gas back pressure

∆m

M%

= 14 x ln (P

M

/P

L1

) – 24 x ln (n

M

/n

L1

)

Fig. 6.04.07: Change of specic exhaust gas amount,

∆m

M%

in % of L

1

value and independent of P

O

∆T

M

= 15 x ln (P

M

/P

L1

) + 45 x ln (n

M

/n

L1

)

Fig. 6.04.08: Change of exhaust gas temperature, ∆T

M

in point M, in °C after turbocharger relative to L

1

value

and valid for P

O

= P

M

178 51 117.2

178 51 130.2

Loading...

Loading...