MAN B&W 9.03

Page 1 of 2

MAN Diesel

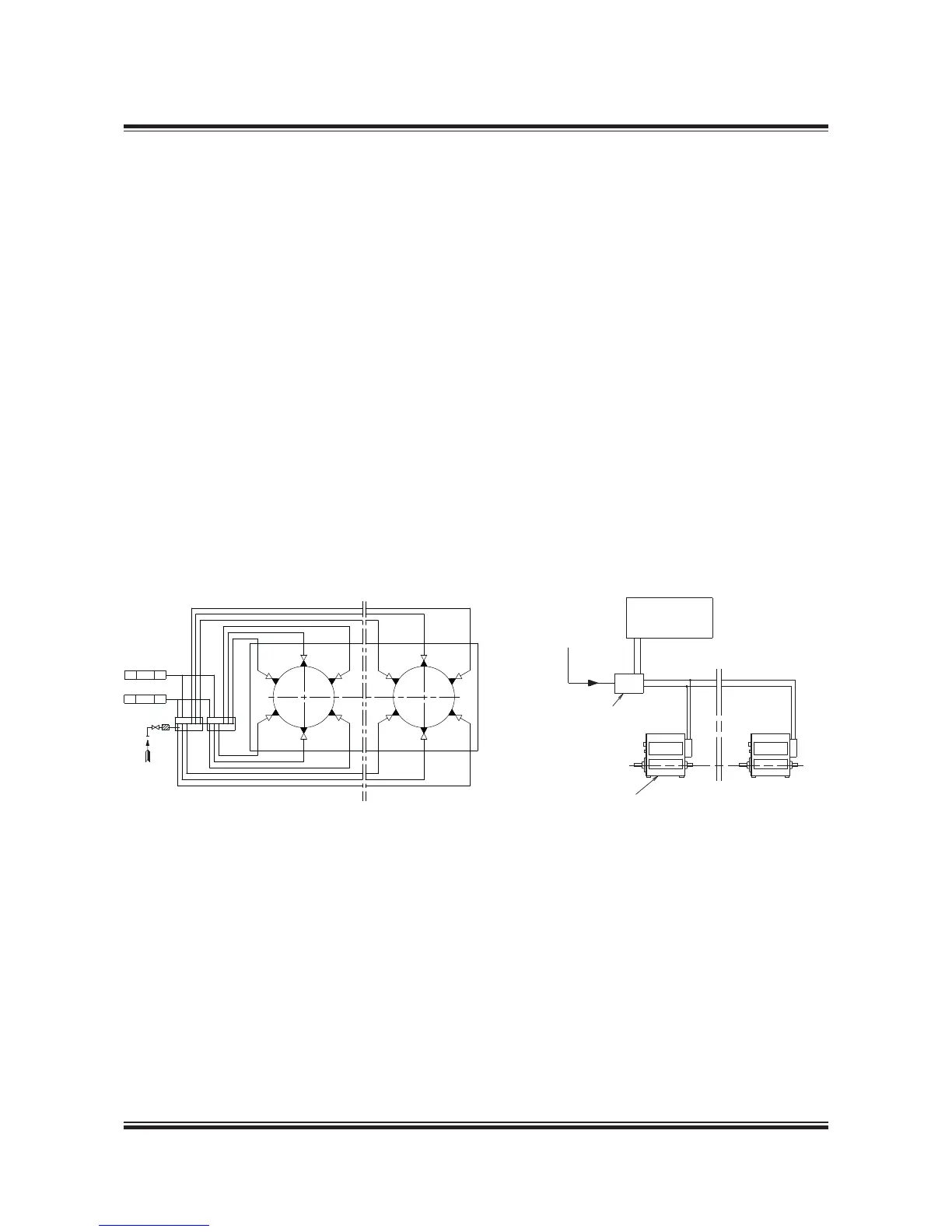

198 59 68-0.1MAN B&W S60MCC7/8, L60MC-C7/8, S50MC6, S50MC-C7/8,

S46MC-C7/8, S42MC7, S40MC-C9, S35MC-C9, S35MC7

178 57 718.0

Fore Aft

58 cylinder engines: 2 Lubricators

912 cylinder engines: 3 Lubricators

AC

LS 8250 AL

FS 8251 AL

The letters refer to list of ‘Counterflanges’

The piping is delivered with and fitted onto the engine

Mechanical Cylinder Lubricators

Mechanical cylinder lubricator(s), can be mounted

on the fore end of the engine, the size of which will

decide the number of lubricators needed. If driven

by the engine in sync with the crankshaft move-

ment, the lubricators could deliver timed injection

of the cylinder lubrication oil.

The lubricator(s) should have a built-in capability

for adjustment of the oil quantity and be provided

with a sight glass for each lubricating point.

The lubricators should be fitted with:

• Electric heating coils

• Low flow and low level alarms.

In the ‘Engine Speed Dependent’ design, the lu-

bricator pumps a fixed amount of oil to the cylin-

ders for each engine revolution.

Mainly for plants with controllable pitch propeller,

the lubricators could, alternatively, be fitted with a

mechanical lubrication system which controls the

dosage in proportion to the Mean Effective Pres-

sure (MEP).

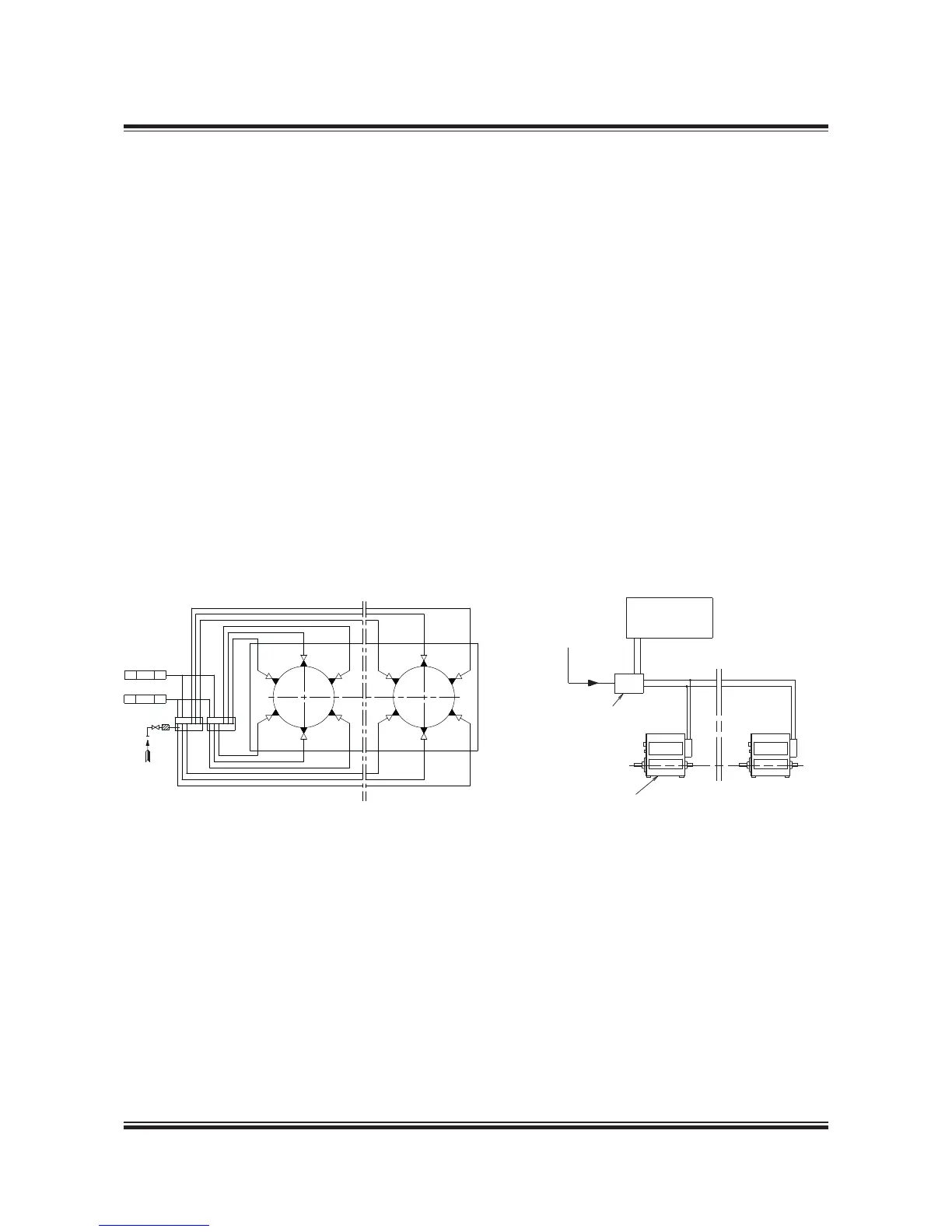

An ‘Engine Speed Dependent’ as well as a ‘MEP

Dependent’ mechanical lubricator could be

equipped with a ‘Load Change Dependent’ sys-

tem, by which the cylinder feed oil rate is auto-

matically increased during starting, manoeuvring

and, preferably, during sudden load changes, see

Fig. 9.03.02.

In that case, the signal for the ‘Load Change De-

pendent’ system comes from the electronic gov-

ernor.

Fig 9.03.01: Piping and instrumentation for a mechani-

cal cylinder lubricator

Fig 9.03.02: Load change dependent mechanical lubri-

cator

178 59 504.0

Loading...

Loading...