GROVE 11-33

CD3340B/YB4411 STRUCTURAL

11

Published 04/07/2015 Control # 569-00

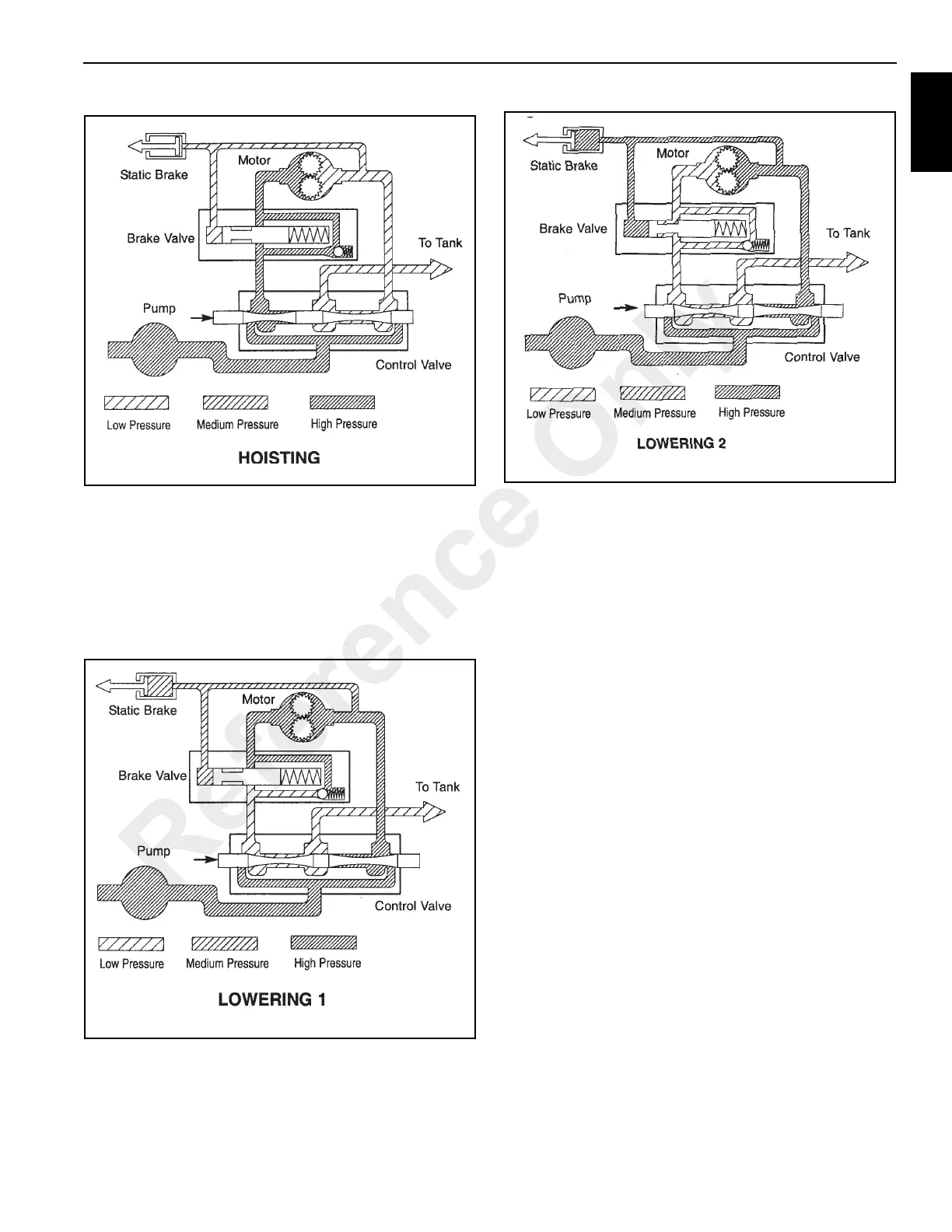

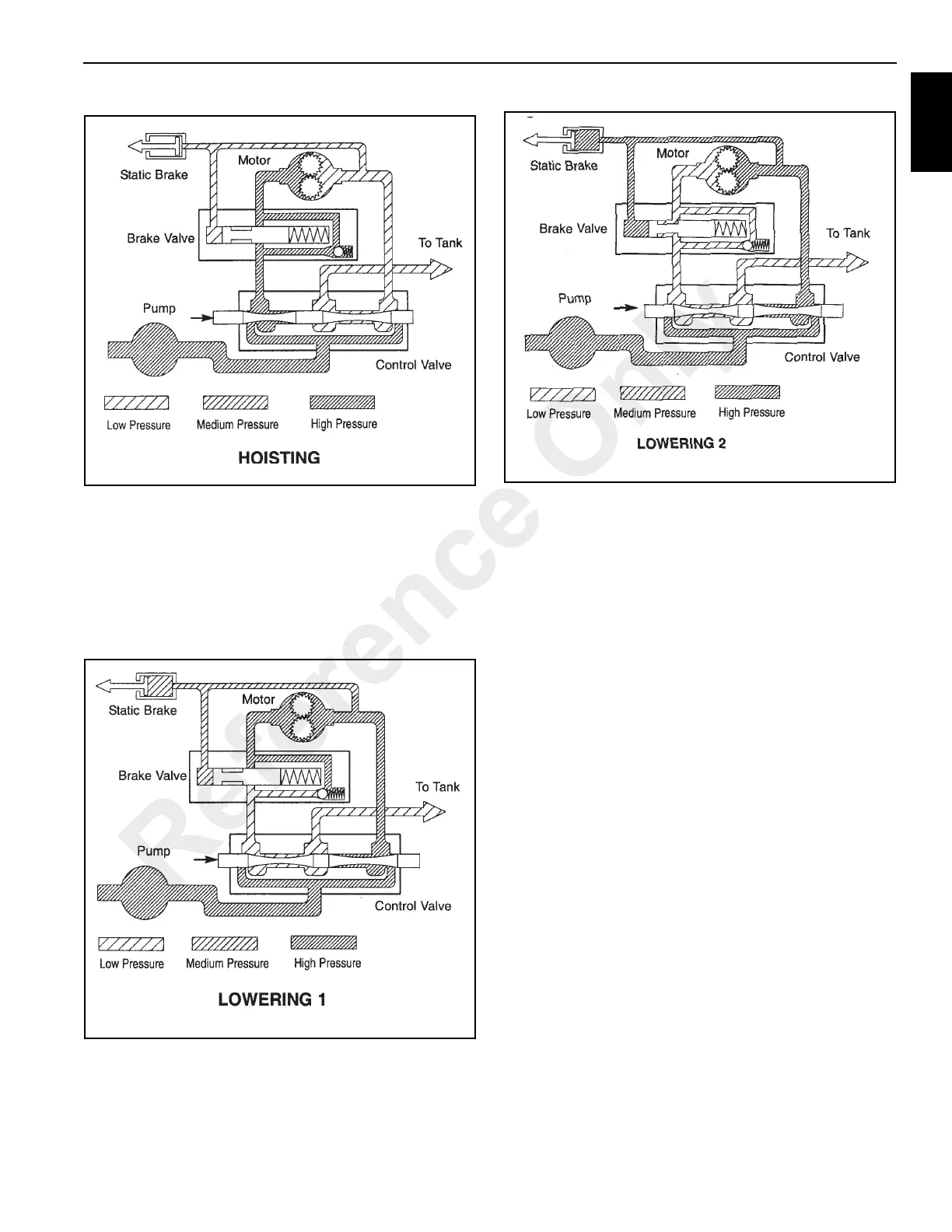

When the control valve is placed in the lowering position, the

spring loaded, pilot operated spool valve remains closed

(Figure 11-69) until sufficient pilot pressure is applied to the

end of the spool valve to shift it against spring pressure;

opening a flow passage (Figure 11-70). After the pilot

operated spool valve cracks open, the pilot pressure

becomes flow-dependent and modulates the spool opening

which controls the lowering speed.

The static brake system has thee operating components

(see Figure 11-67):

1. Spring applied, multiple friction disc static brake

2. Brake clutch assembly

3. Hydraulic piston and cylinder

The static brake is released by the brake valve pilot pressure

at a pressure lower than that required to open the pilot

operated spool valve. This sequence assures that dynamic

braking takes place in the brake valve and that little, if any,

heat is absorbed by the friction brake.

The friction brake is load holding brake only, and has nothing

to do with dynamic braking or rate of descent of a load.

The brake clutch is spline to the primary sun gear shaft

between the motor and the primary sun gear. It will allow this

shaft to turn freely in the direction to raise a load and lock up

to force the brake discs to turn with the shaft in the direction

to lower a load. See Figure 11-71 and 11-72.

The hydraulic cylinder, when pressurized will release the

spring pressure on the brake disc, allowing the brake discs to

turn freely.

Reference Only

Loading...

Loading...