STRUCTURAL CD3340B/YB4411

11-42

Published 04/07/2015 Control # 569-00

rope in. An easy way to check the rotation is to hold the

outer race in one hand, and rotate the inner race.

If the clutch free wheels in the wrong direction,

disassemble the clutch and reverse the inner race. Refer

to “Brake Clutch Service, on page 11-49 for additional

information.

14. If the brake discs are misaligned: preventing the

installation of the clutch, then with a hand pump, apply

750-1000 psi to the brake release port. The brake discs

will move freely with the brake released, permitting

alignment of the discs, brake clutch and input sun gear.

15. Install the hoses and fittings to the brake cylinder

release port (Figure 11-95)

16. Install a new O-ring on the motor pilot then lubricate with

petroleum jelly or gear oil.

NOTICE!

Care must be taken to assure the primary thrust plate

remains properly located in its counter bore when the

motor is installed for the first time, or is being reinstalled

on the hoist. It is possible for the primary thrust plate to

drop out of its counter bore and become wedged

between the planet gears and the planet carrier. If the

hoist is operated with the primary thrust plate wedged

between primary gears and the planet carrier, or with a

thrust washer out of position, severe damage to internal

hoist components could result.

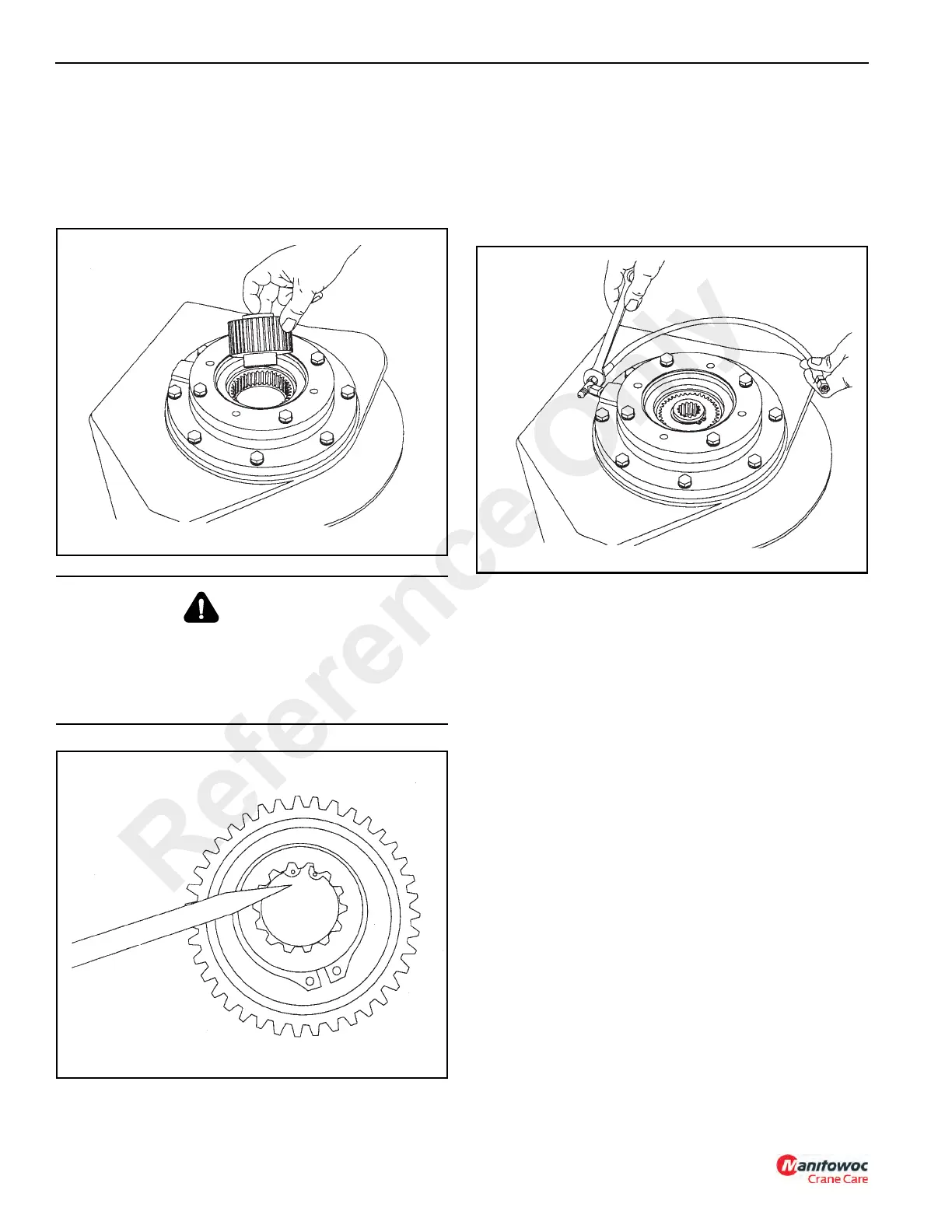

17. Measure the distance from the motor mounting surface

to the inner brake race (Figure 11-96). With all

components properly installed, this distance should be

17.5 mm (11/16 in) to 19.1 mm (3/4 in). If this distance is

less than 14.3 mm (9/16 in), the primary spacer may be

positioned as shown in Figure 11-97 and should be

checked.

WARNING

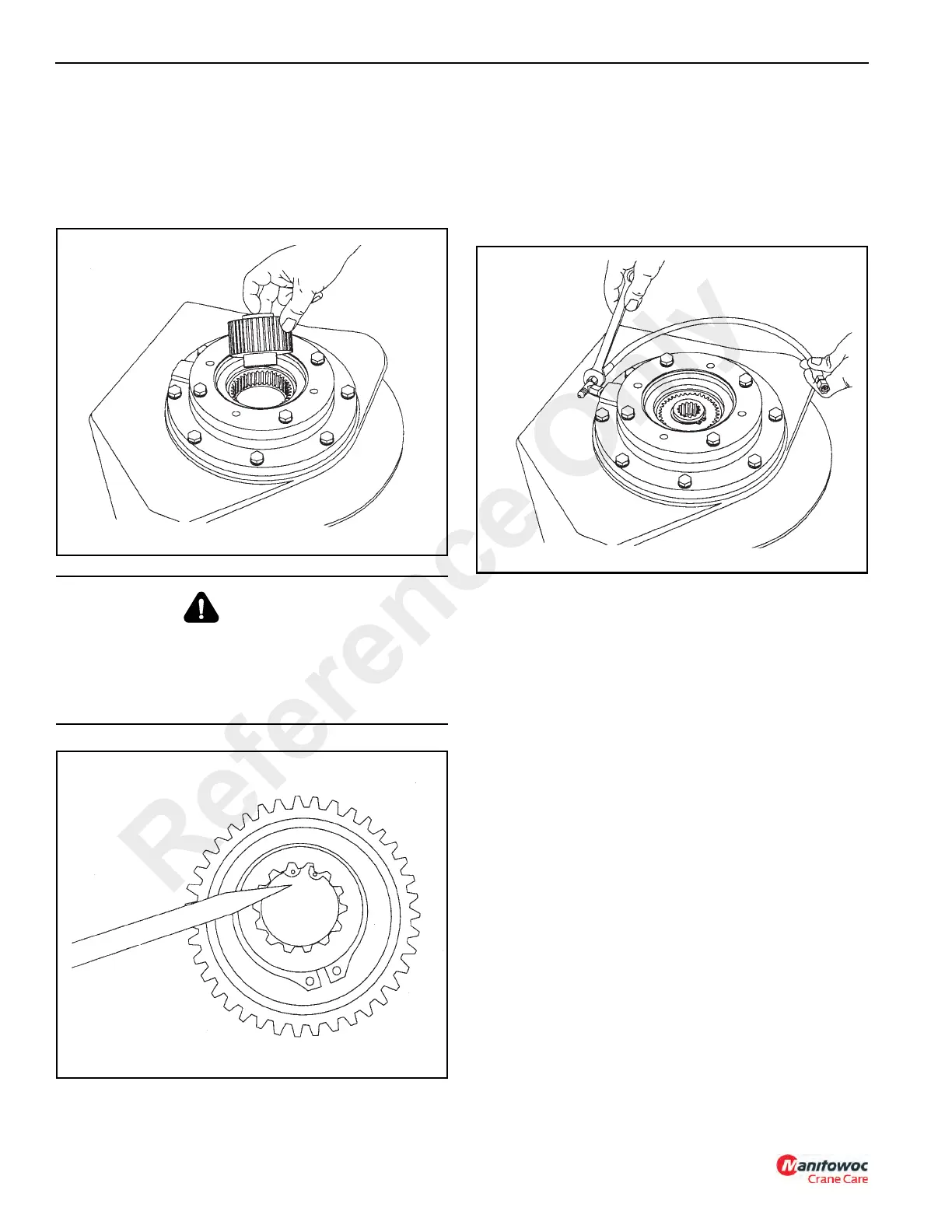

Be certain the snap ring (Figure 11-94) is seated in the

groove in the spline bore of the inner race. This snap ring

will keep the brake clutch assembly correctly positioned in

the center of the friction brake pack. Binding of the brake

or brake failure may occur if this snap ring is omitted.

Reference Only

Loading...

Loading...