UNDERCARRIAGE TMS700E SERVICE MANUAL

8-42 Published 01-29-2015, Control # 512-01

Apply brake lubricant to all parts except the linings and

drums to prevent rust.

Inspect Parts

1. Check the spider for expanded anchor pin holes and

cracks. Replace damaged spiders and anchor pin

bushings.

2. Check the camshaft bracket for broken welds, cracks,

and correct alignment.

3. Check anchor pins for corrosion and wear. Replace

damaged anchor pins.

4. Check brake shoes for rust expanded rivet holes, broken

welds, and correct alignment. Anchor pin holes must not

exceed 26 mm (1.03 in) in diameter. The distance from

the center of the anchor pin hole to the center of the

roller hole must not exceed 327 mm (12.875 in).

5. Check the camshaft for cracks, wear, and corrosion.

Check the cam head, bearing journals, and splines.

6. Check the slack adjuster for the gap between the clevis

and collar. If the gap exceeds 1.5 mm (0.060 in), replace

the clevis. Check the clevis pins and bushing in the slack

adjuster arm. Replace bushing if diameter exceeds

16.6 mm (0.65 in).

7. Rotate the slack adjuster adjusting nut through a 360

degree rotation (about 22 turns of the adjusting nut) with

a torque wrench. Torque must be less than 2.8 Nm

(25 lb-in) for a new or rebuilt slack adjuster.

8. Check the brake drums for cracks, severe heat

checking, heat spotting, scoring, pitting, and distortion.

9. Measure the inside diameter of the drum in several

locations and replace if diameter exceeds

manufacturers specifications.

10. Check dust shields for rust and distortion. Replace as

necessary.

Assemble Brakes

Each time the brakes are relined, the following parts should

also be replaced.

• Springs

• Rollers

• Anchor Pins

• Clevis Pins

• Camshaft Seals

Camshaft Installation

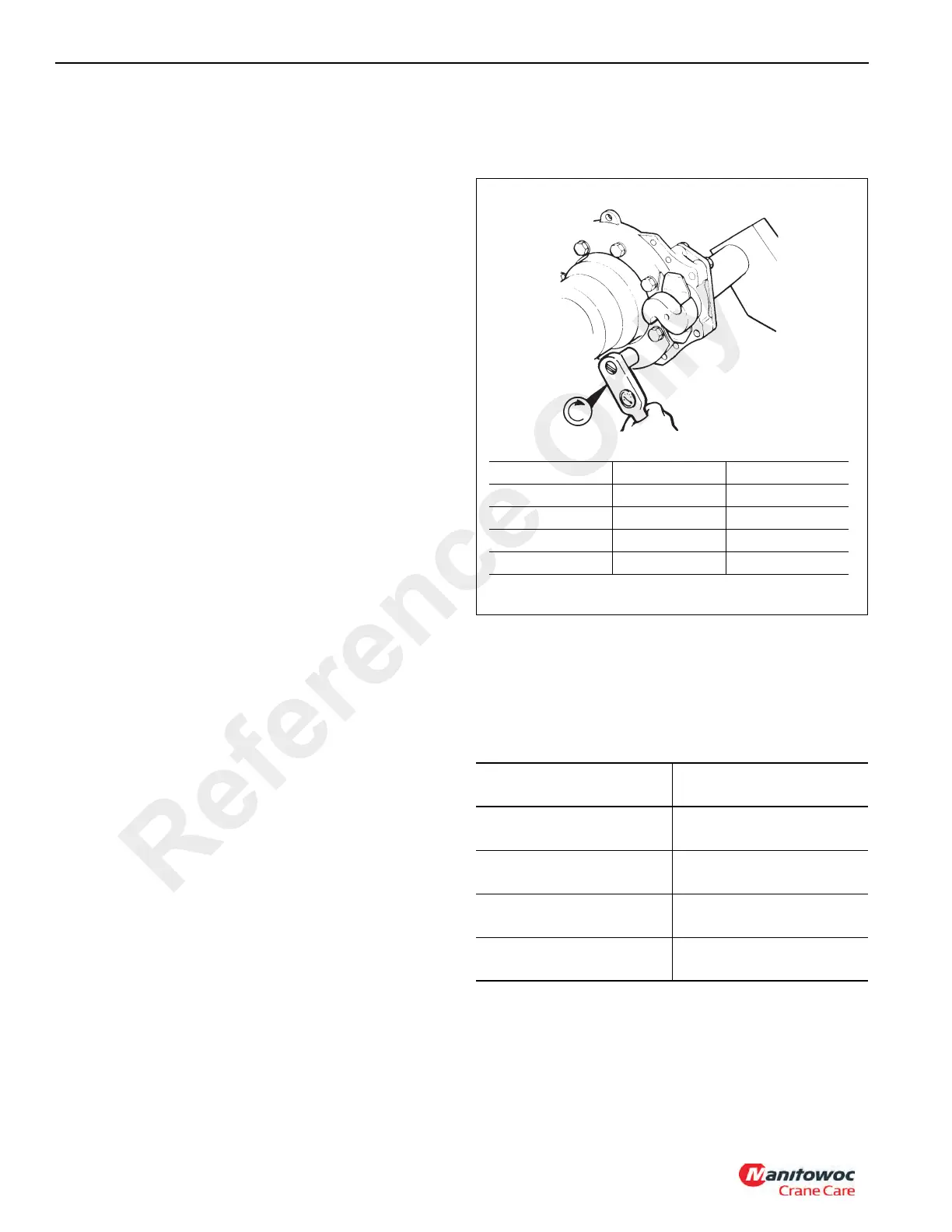

1. Check all spider bolts for the correct torque (see

Figure 8-45).

2. Install new camshaft seals and, if required, bushings in

both the spider and camshaft bracket. Use a seal driver

to install the bushings.

3. If the camshaft bracket was removed, install the gasket

and bracket to the spider. Torque per Table 8-4.

Table 8-4

NOTE: Install both seals with lips toward slack adjuster

(see Figure 8-46).

4. Put the cam head thrust washer on the camshaft. Apply

O-617 - A or B chassis grease to the camshaft bushings

or needle bearings and to the camshaft journals. Install

Size and Grade

Torque

Nm (pounds-foot)

1/2”-13 Grade 8

122 to 163 Nm

(90 to120 lb-ft)

1/2”-13 Grade 5

88 to 136 Nm

(65 to 100 lb-ft)

5/8”-18 Plain Nut

203 to 258 Nm

(150 to 190 lb-ft)

5/8”-18 Lock Nut

176 to 224 Nm

(130 165 lb-ft)

FIGURE 8-45

Bolt Size Nm Pounds-Foot

7/16” - 20 85 - 102 60 - 75

1/2” - 20 115 - 156 85 - 115

9/16” - 18 176 - 224 130 - 165

1/8” - 18 244 - 312 180 - 230

Reference Only

Loading...

Loading...