Manitowoc Published 08-06-19, Control # 237-09_v2 4-3

MLC165-1 OPERATOR MANUAL SETUP AND INSTALLATION

HOSE AND CABLE CLEANLINESS

To prevent dirt from entering the hydraulic systems or from

damaging the electric connectors:

• Thoroughly clean the hydraulic fittings and the electric

connectors before connecting them.

• Thoroughly clean the dust caps before attaching them to

hoses, tubes, or cables.

• Do not drag the hydraulic hose fittings, the hydraulic

hoses, the electric cable connectors, or the electric

cables on the ground.

• Apply a light coat of silicone lubricant to the threads of all

dust caps, couplers, and connectors to help in

preventing the threads from seizing.

CONNECTING/DISCONNECTING

HYDRAULIC HOSES AND ELECTRIC

CABLES

Always STOP ENGINE before performing the following steps

during crane assembly and disassembly:

• Connecting and disconnecting hydraulic lines. It will be

easier to connect and disconnect the couplers when

there is no pressure in the system.

• Connecting and disconnecting electric cables. The

potential for operating faults or damage to the electric

components exists if the engine is not stopped.

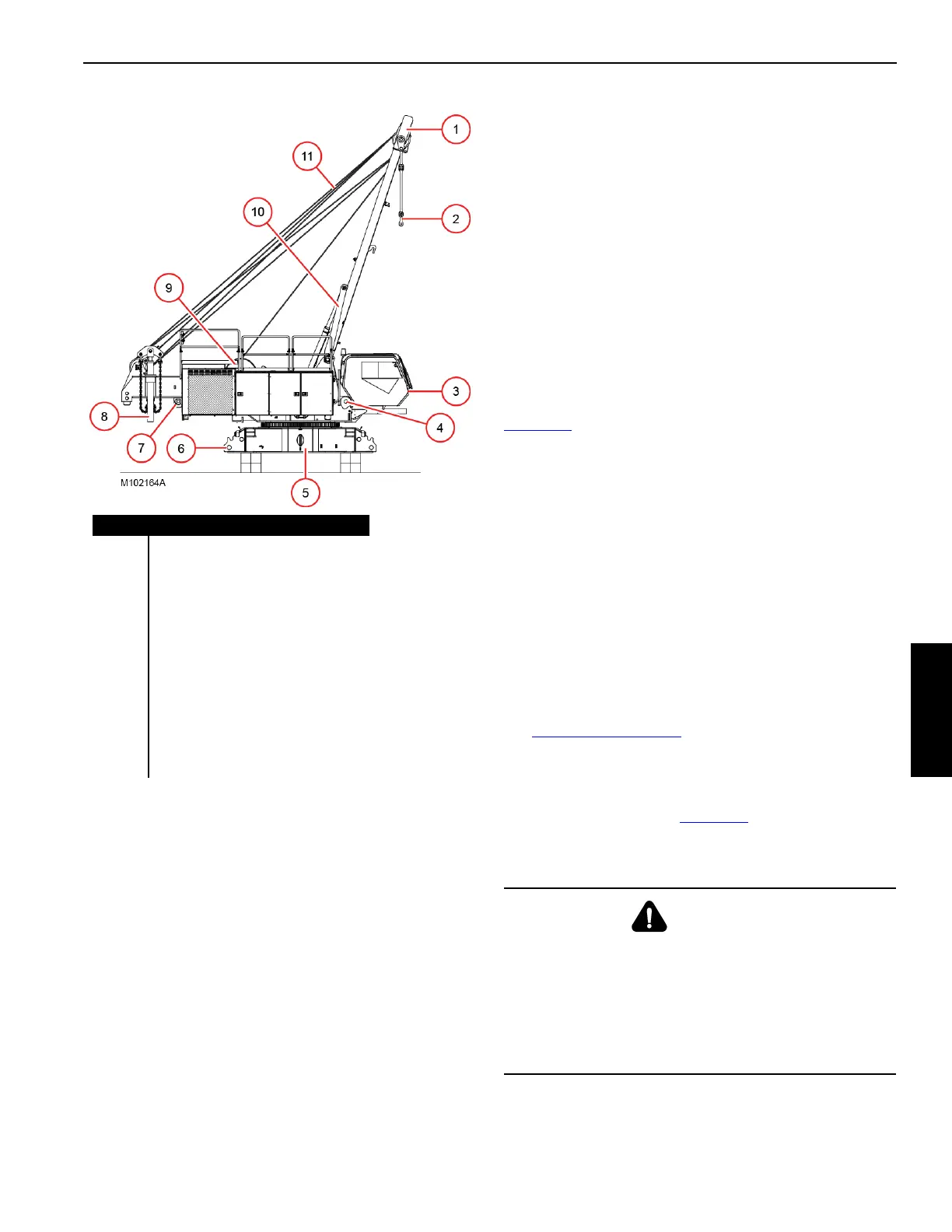

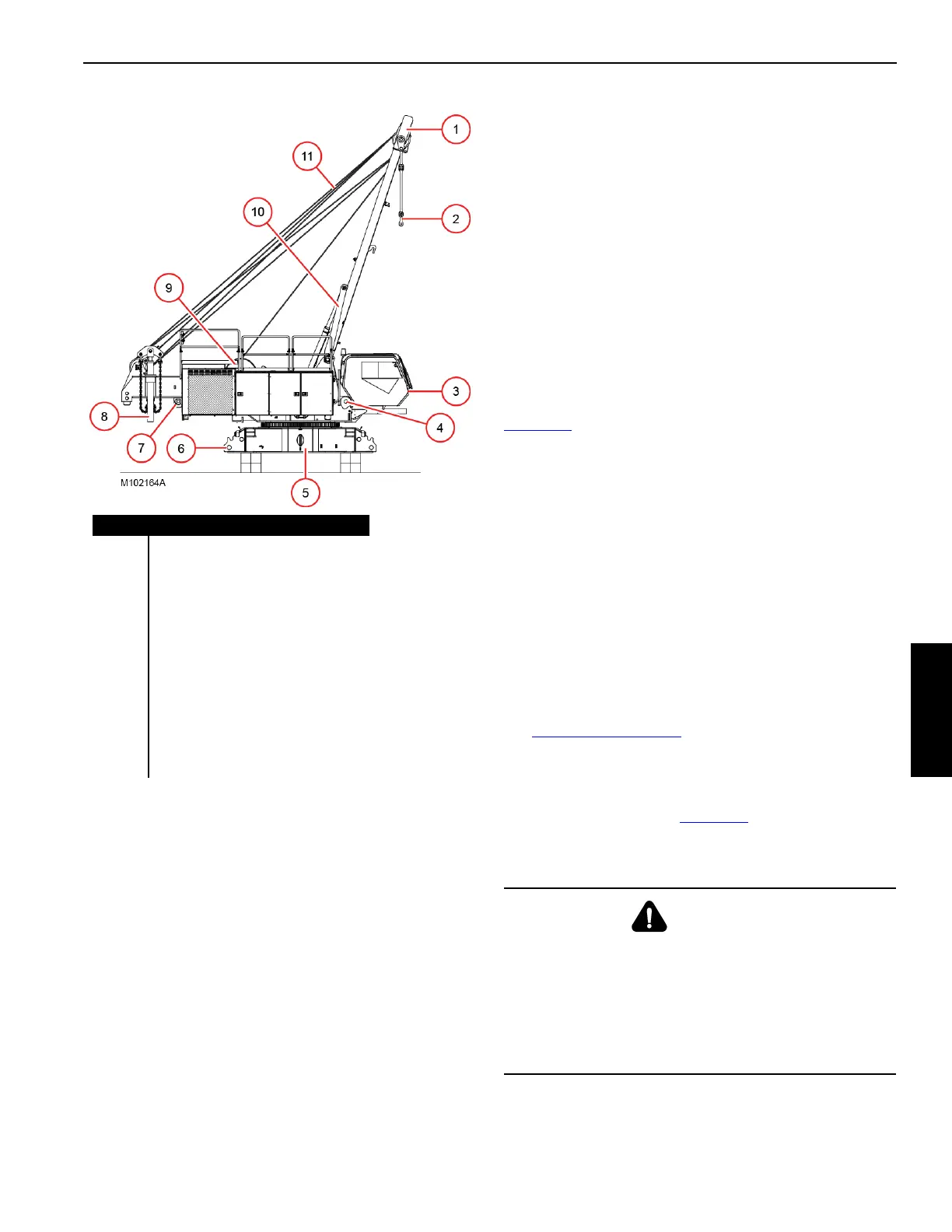

SELF-ASSEMBLY COMPONENTS

The crane is equipped with the following hydraulically

actuated assembly/disassembly components (see

Figure 4-1

):

• Boom hinge pins (4) for connecting the boom butt to the

rotating bed.

• Crawler pins (6) for connecting and disconnecting the

crawlers to and from the carbody.

• Inner counterweight pins (7) for connecting and

disconnecting the counterweight to and from the rotating

bed.

• Counterweight cylinders (8) for installing and removing

the crane counterweight.

• Mast-assist arms (10) for raising the mast to the

operating position and lowering it to the transport

position.

• Controls for operating the above components (see

Figure 4-2 on page 4-4

).

LOAD SENSING PINS

At the crane owner’s discretion for duty-cycle operation only,

the load sensing pins (12, Figure 4-1

) can be replaced with

the mast-to-boom link pins located in the parts box. See the

RCL/RCI Operation Manual for details.

Item Description (Qty)

1Mast

2 Mast-to-Boom Links

3Operator Cab

4 Boom Hinge Pin (2)

5 Carbody

6 Crawler Pin (4)

7 Inner Counterweight Pin (2)

8 Counterweight Cylinder (2)

9 Boom Hoist

10 Mast Assist Arm

11 Boom Hoist Wire Rope

12 Load Sensing Pin (2)

Figure 4-1

WARNING

Tipping/Structural Damage Hazard!

To prevent tipping or structural damage:

• The load sensing pins must be installed for all

liftcrane operations AND

• the proper liftcrane capacity chart must be selected in

the RCL/RCI display.

Loading...

Loading...