SETUP AND INSTALLATION MLC165-1 OPERATOR MANUAL

4-130

Published 08-06-19, Control # 237-09_v2

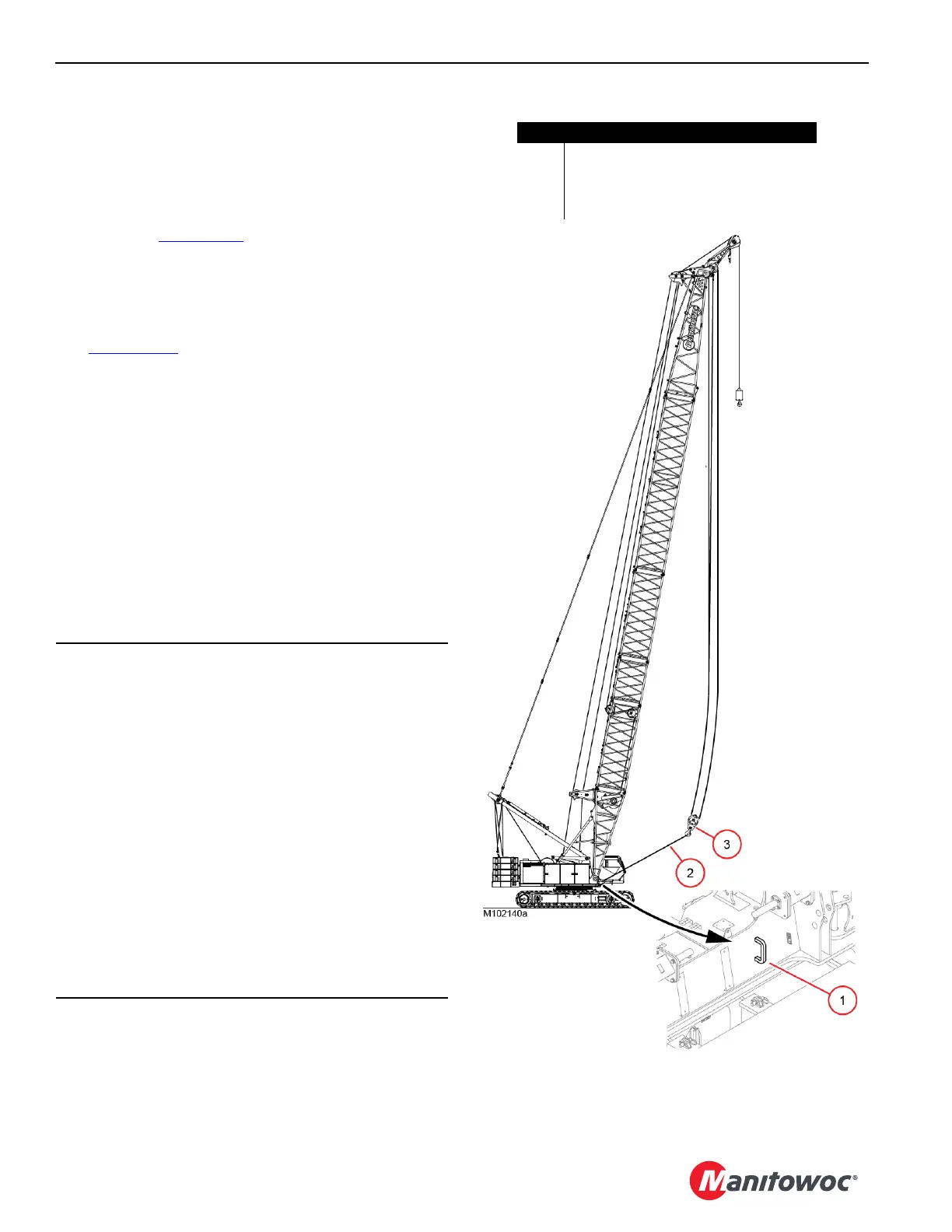

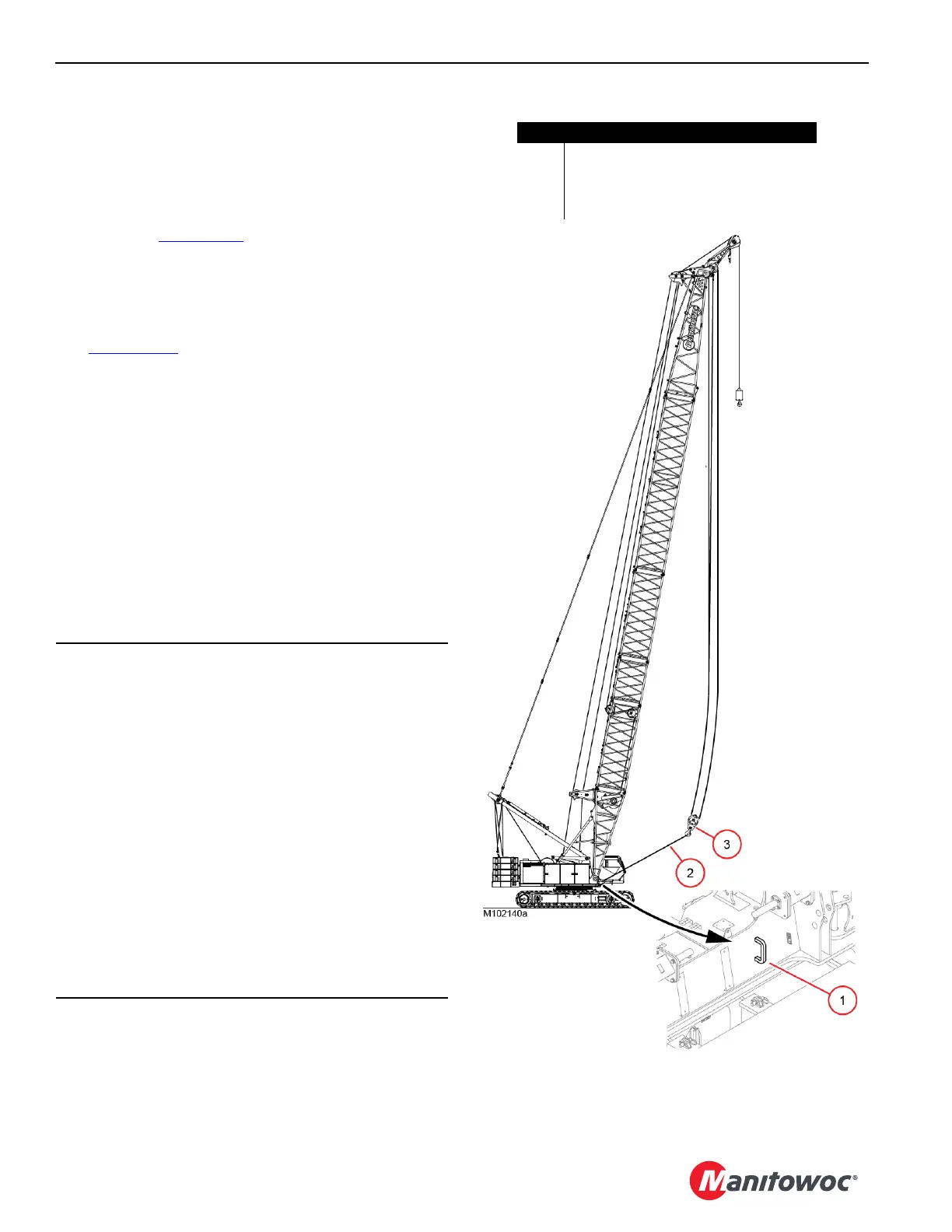

LOAD BLOCK TIEBACK

Standard on crane s/n 91651011 and above. Contact the

Manitowoc Crane Care Lattice Team for field installation on

cranes built prior to Serial Number 91651011.

General

Tieback lug (1, Figure 4-102) is provided on the front of the

rotating bed for tying back the load block when not in use.

Specifications

Shackle

See Figure 4-102 for the tieback opening size. Size the

shackle accordingly.

Sling Length

The sling must be long enough to connect it to the shackles

in the tieback holes and to the hook of the freely suspended

load block. This will prevent personnel from having to swing

the block in, toward the crane, to make the connection.

Sling Capacity

The sling must be capable of supporting the weight of the

load block and 1/2 the weight of the wire rope suspended

from the boom point. When sizing the sling, take into account

the dynamic affects of traveling and swinging the crane. It is

the crane user’s responsibility to calculate this load.

CAUTION

Avoid damage:

• Haul in the load line only until the tieback sling is taut.

The purpose of the tieback is only to prevent the load

block from swinging when not in use.

• Do not tighten the load line to the point that the load

line rubs against the lacings in the boom sections or

to the point that the load block can bounce into the

lacings.

• Operator, be aware that as you boom down, the load

lines and tieback sling will tighten even more. Pay out

the load line while booming down so that you don’t

pull the load block into the boom. Damage to lacings

or chords could result.

• Only use the lug for tying back the load block. Using

the lug for any other purpose could result in damage

to the lug and the rotating bed.

Item Description

1 Tieback Lug with

2-1/2 in (64 mm) x 6 in (152 mm) Opening

2 Sling with Shackles (owner furnished)

3 Load Block

Figure 4-102

Loading...

Loading...