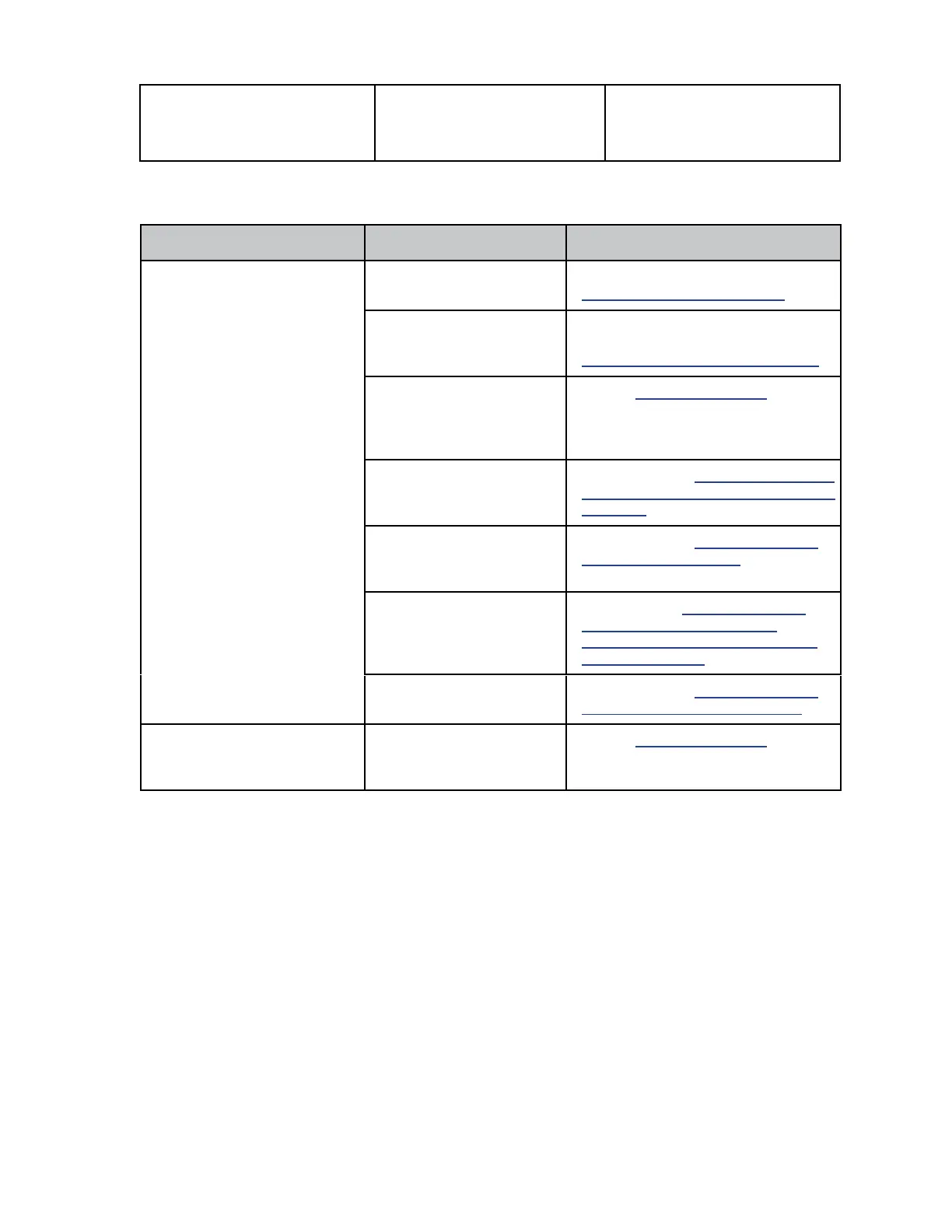

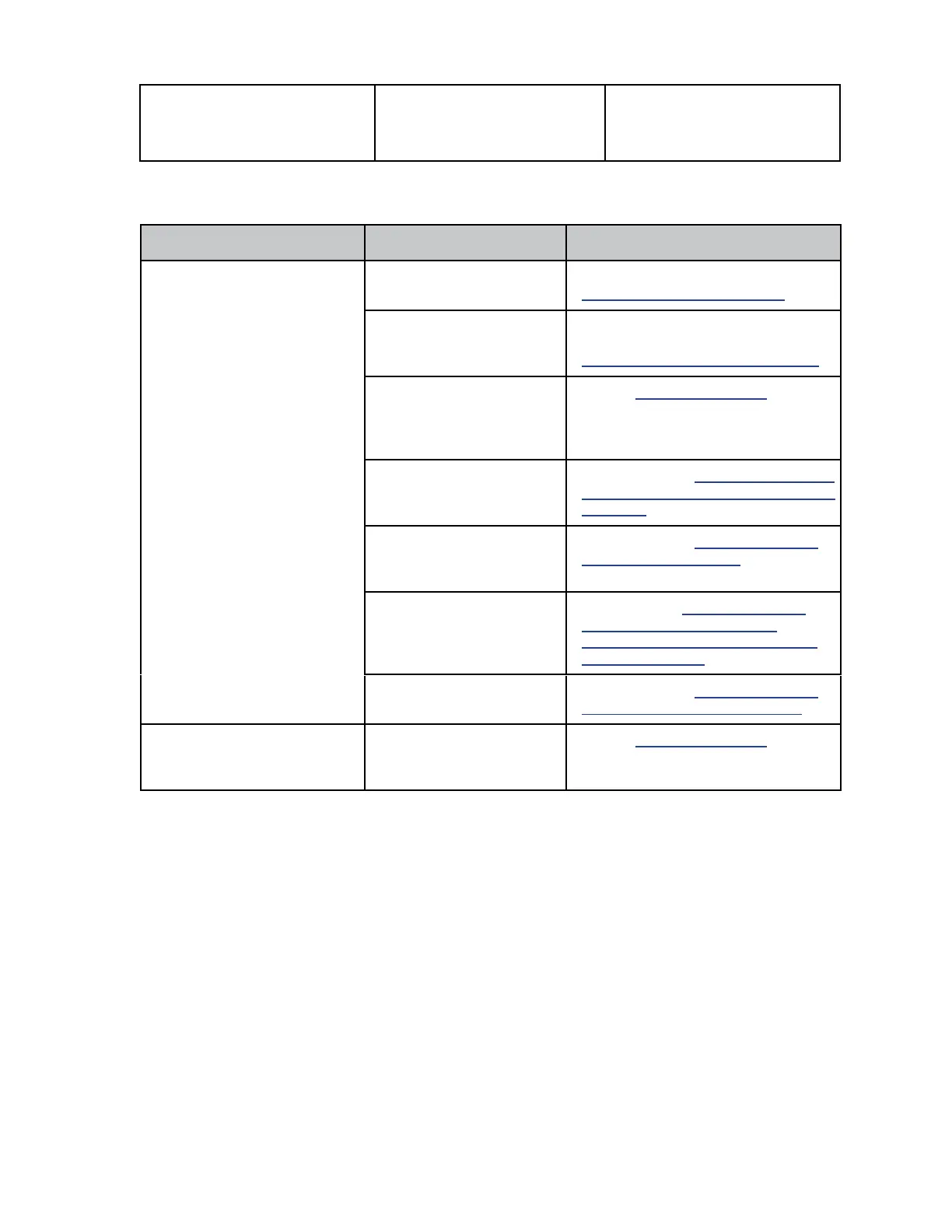

Comet Executive Gas Troubleshooting

6-11

WARNING

Only trained personnel with experience

in gas, electrical or mechanical repair

should troubleshoot and repair the unit.

Troubleshooting

WARNING

Read the REPAIR chapter and make

sure that the power is disconnected

before doing any repairs.

ISSUE POSSIBLE CAUSE SOLUTION

Poor Flatwork Finish

1. Feeding technique is im-

proper.

• Use correct feeding techniques. Refer to

Flatwork Handling on page 3-9.

2. Ironing section controls are

incorrectly set for the linen

being processed.

• Check the TEMPERATURE Control and

the setting of SPEED knob. Refer to

Processing Standards on page 3-15

3. Ironing cylinder is not being

waxed at least once a day

(Does not apply to chrome

ironing cylinders).

• Refer to Waxing on page 3-7.

4. Return ribbon drive roll

friction material is worn

smooth.

• Replace. Refer to Return Ribbon Drive

Roll Friction Material Replacement on

page 7-40.

5. Return ribbons are exces-

sively worn and are not

moving flatwork correctly.

• Replace. Refer to Return Ribbon Re-

placement on page 7-38.

6. Compression roll pressure

is not even from side to

side.

• Adjust. Refer to Compression Roll

Pressure Check on page 7-17 and/or

Compression Roll Pressure Adjust-

ment on page 7-18.

7. Compression roll padding

is worn.

• Replace. Refer to Compression Roll

Cover Replacement on page 7-19.

Flatwork Sticks to Return Rib-

bons/Exits Ironer with Exces-

sive Static

1. Chrome ironing cylinder

needs waxing.

• Refer to Waxing on page 3-7.

Loading...

Loading...