Comet Executive Gas Repair

7-23

7.5 Ironing Section

The following procedures should be used

to keep the ironing cylinder and other ironing

section components operating properly:

• Drive Chain Tension Adjustment

• Ironing Cylinder Reconditioning

• Ironing Cylinder Hardened Ring

Replacement

Drive Chain Tension Adjustment

The drive chain in the right endframe powers

the feed ribbon and return ribbon drive rolls as

well as the ironing cylinder. The chain has an

adjustable tensioning arm.

Over time, the drive chain may stretch

slightly from the eects of heat and stress. If the

unit becomes excessively noisy, or if the drive

mechanisms work unevenly because of chain

slippage, it will be necessary to adjust the tension

on the chain.

Required Tools

Wrenches:

11/16”

1-3/8” or Crescent

Perform only when the unit is OFF

with power disconnected and COOL.

1. Turn power OFF at the main disconnect

switch.

2. Open the right endframe door.

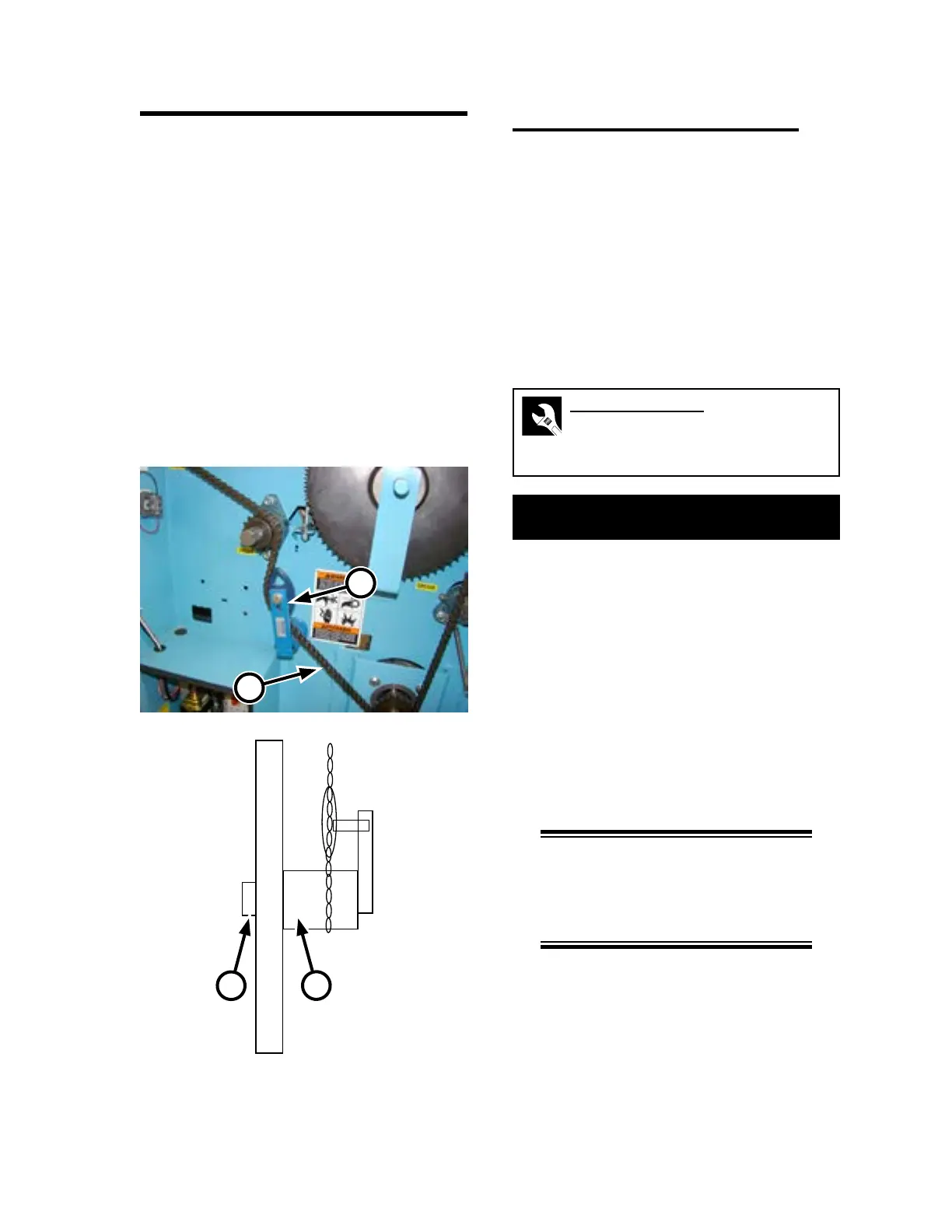

3. Check the drive chain (Figure 7-22, A)

for excessive movement. There should be

very little free play in the chain.

4. Tension on the drive chain is kept by an

idler arm chain tensioner (Figure 7-22, B).

When tension on the chain becomes loose,

adjust the idler arm tensioner.

NOTE: A stretched chain that

has been adjusted may not t the

sprocket correctly and may need

to be replaced.

5. Locate the idler arm mounting bolt (Figure

7-22, C) on the inside of the endframe.

6. Loosen the idler arm mounting bolt just

enough to allow turning of the idler arm

base with a crescent wrench.

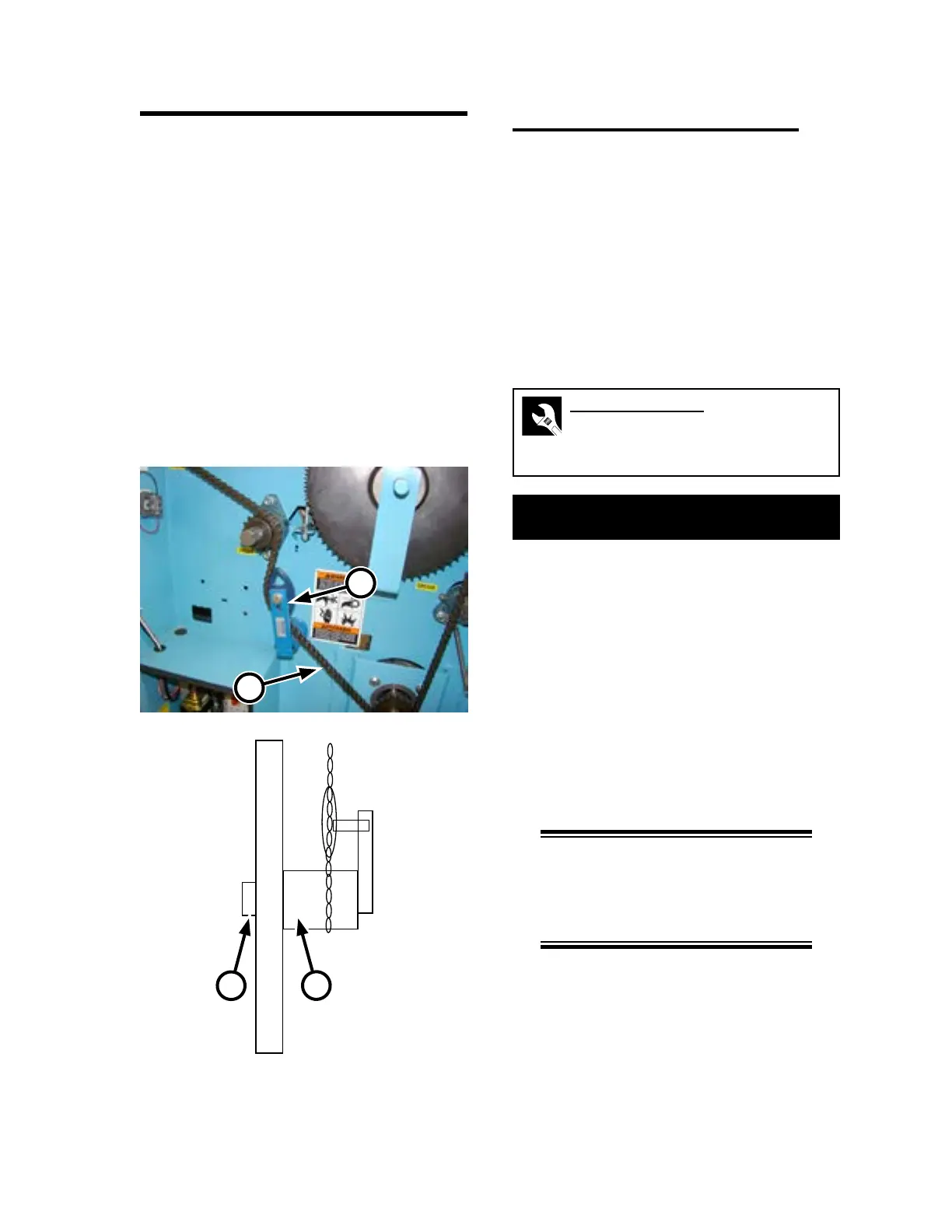

Mounting Bolt

Drive Chain

Endframe

Tension Idler Arm

Figure 7-22: The drive chain is adjusted using the

tensioning idler arm.

A

B

C

D

Loading...

Loading...