Preventive Maintenance Comet Executive Gas

4-14

Grease Bearings

Required Tools

Clean cloth

Grease gun

Grease: EP, bentonite clay, NLGI 2,

1000 cSt viscosity

Perform only when the unit is OFF

with power disconnected and COOL.

Bearings marked with yellow “GREASE”

tags are not subjected to as much stress and high

temperatures as the bearings that require weekly

greasing.

Therefore, the bearings with yellow “GREASE”

tags do not need to be greased as frequently as

the bearings with yellow “GREASE WEEKLY”

tags. Use the same high temperature grease for

all the bearings.

For instructions on greasing bearings labeled

with yellow “GREASE” tags, refer to Grease

“Weekly” Bearings on page 4-8.

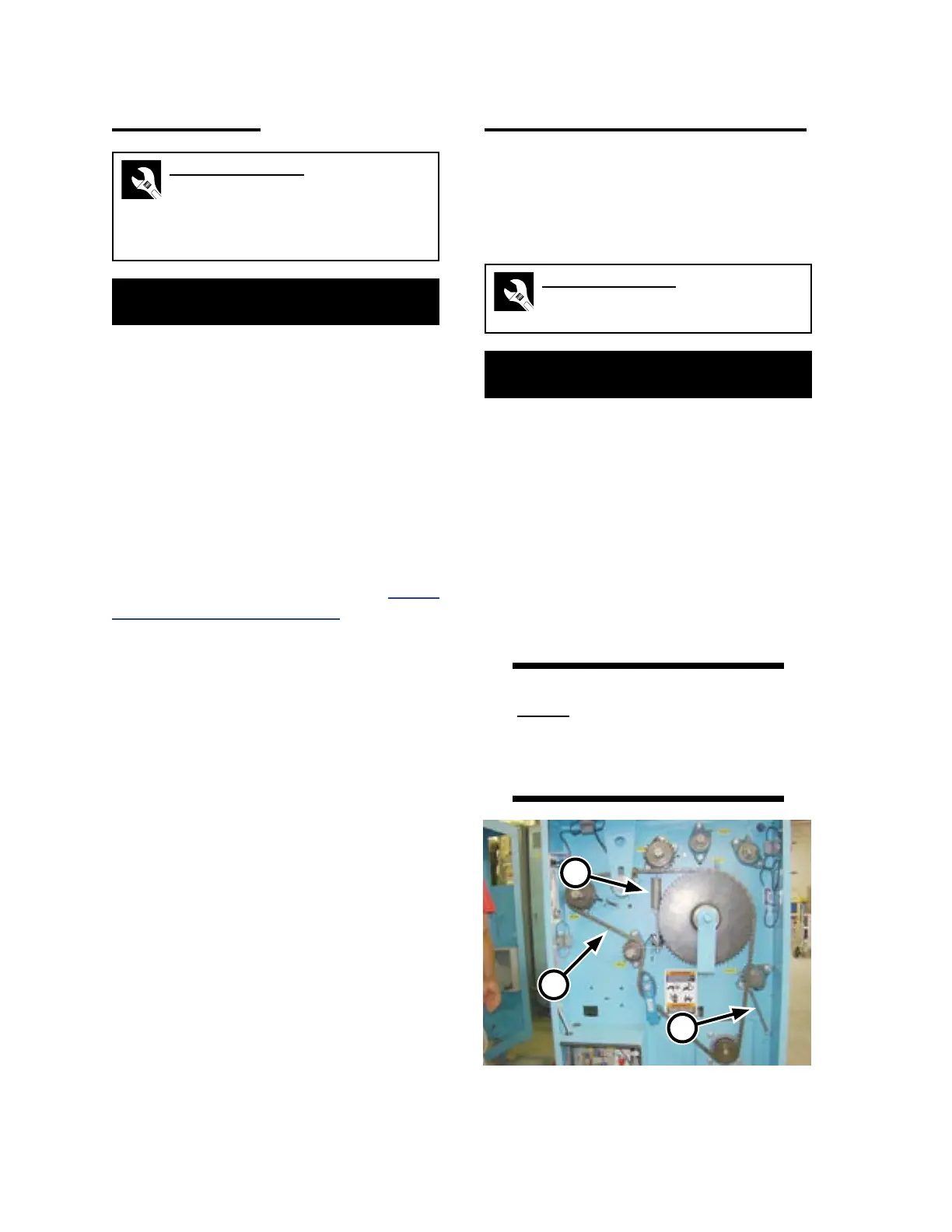

Oil Drive Chain and Tension Springs

The drive chain in the left endframe (Figure

4-10, A), and the compression roll tensioning

springs (B), and return ribbon tensioning

springs (C) in both endframes require monthly

maintenance.

Required Tools

Clean cloth

SAE 90 grade oil

Perform only when the unit is OFF

with power disconnected and COOL.

1. Turn power OFF at the main disconnect

switch.

2. Open both endframe doors.

3. Clean o old lubricant from the drive

chain and tensioning springs.

4. Lightly lubricate the chain and springs

with a good quality SAE 90 grade oil.

5. Close and secure both endframe doors.

WARNING

Never operate the unit unless

all safety covers are in place

and all safety equipment is

working correctly.

Figure 4-10: The drive chain is located inside the

right endframe.

B

C

A

Loading...

Loading...