Comet Executive Gas Installation

2-3

2.2 Installation

Procedures

Installation procedures of the unit include the

following.

• Inspection

• Uncrating and Positioning

• Exhaust Blower Installation

• Electrical Connection

• Gas Connection

• Receiving Shelf Set-Up

• Final Protective Wrapper Removal

Inspection

Carefully inspect all shipments before they are

accepted from the carrier. Upon delivery, make

sure all items listed on the bill have been received.

Any shortage, breakage, or damage noticed at

the time of delivery should be indicated on the

carrier’s freight bill and signed by the driver or

carrier’s representative.

Damage noticed after delivery should be

reported to the carrier at once. Request their

inspection of the shipment, and fill out a

concealed damage inspection report.

NOTE: Notify the carrier

immediately if any damage has

been done to the unit during

shipment.

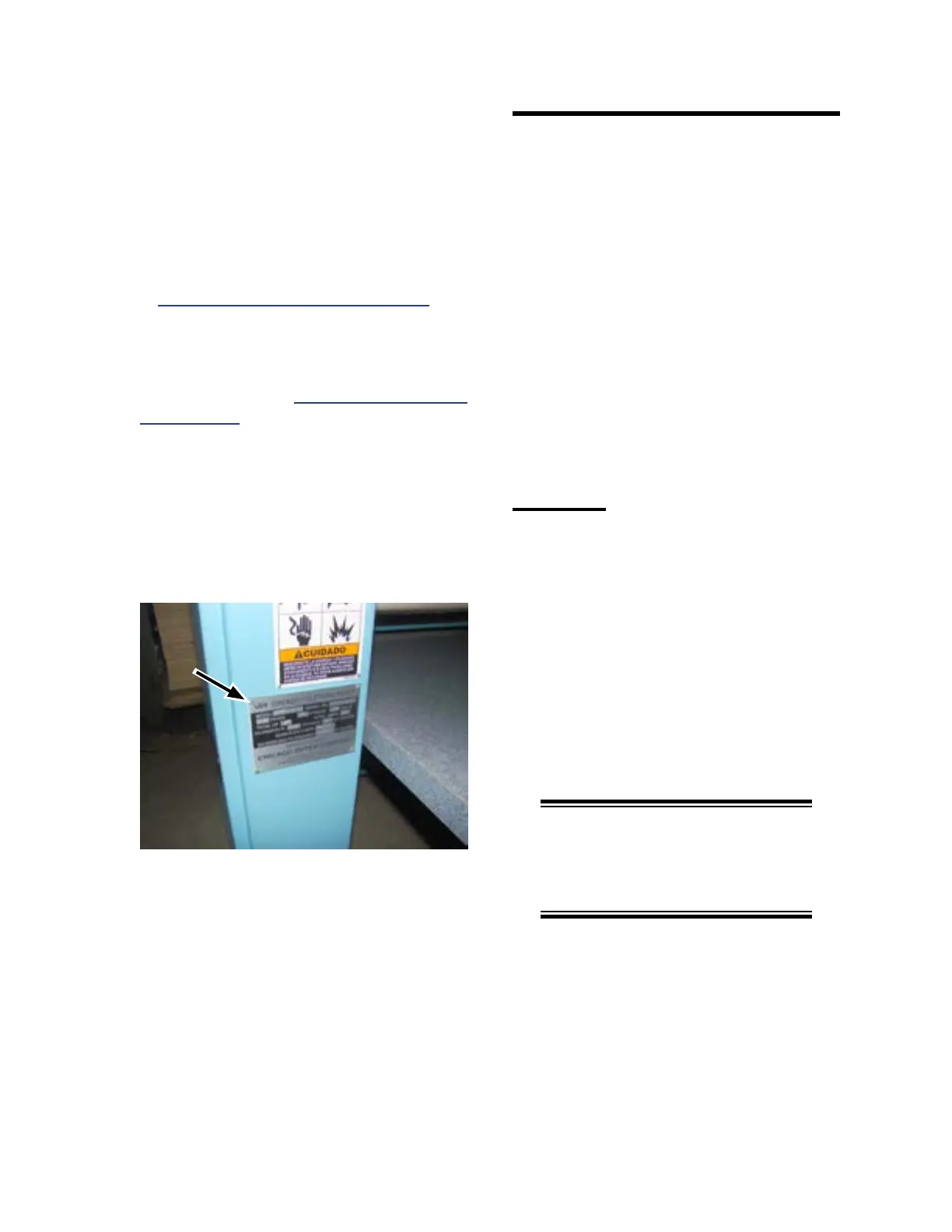

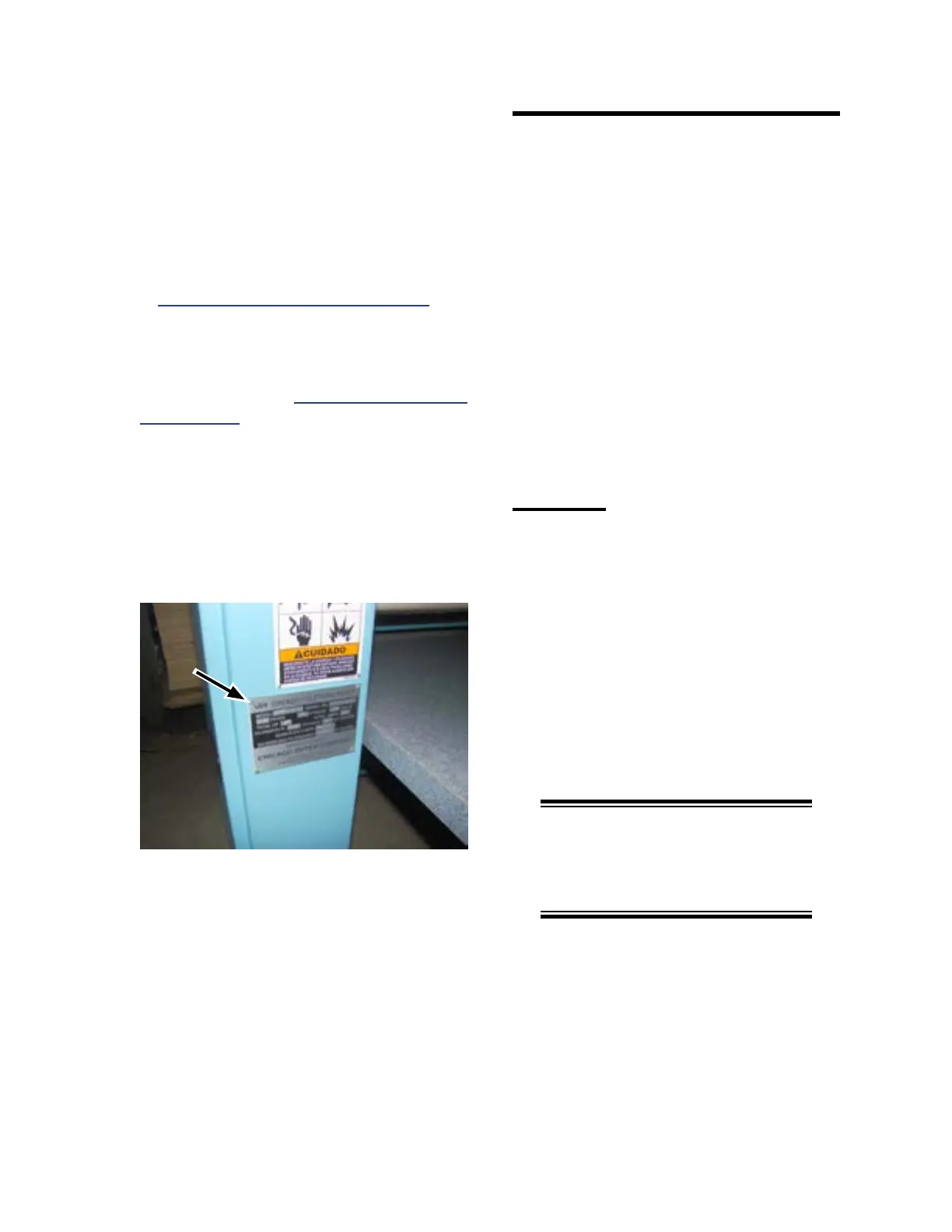

The electrical requirements of the unit are

shown on the nameplate (Figure 2-2), located

on the front of the left endframe. Wiring and a

separate, fused disconnect switch of suitable size

must be locally supplied if local codes require

one.

Check local codes for clearance requirements

to any electrical box. For more information, refer

to APPENDIX: Technical Specications.

Each unit has specic gas requirements; verify

the local gas supply matches the gas requirements

specified on the unit’s nameplate. For more

information, refer to APPENDIX: Technical

Specications.

Note that the nature of the atmospheric burner

used in the machine prevents it from operating

at full capacity when in use above an altitude of

approximately 2000 feet (609 meters). For use

at higher elevations, contact the factory service

department.

Figure 2-2: The nameplate contains important

information, including information

about altitude usage.

Loading...

Loading...