Troubleshooting Comet Executive Gas

6-6

WARNING

Only trained personnel with experience

in gas, electrical or mechanical repair

should troubleshoot and repair the unit.

Troubleshooting

WARNING

Read the REPAIR chapter and make

sure that the power is disconnected

before doing any repairs.

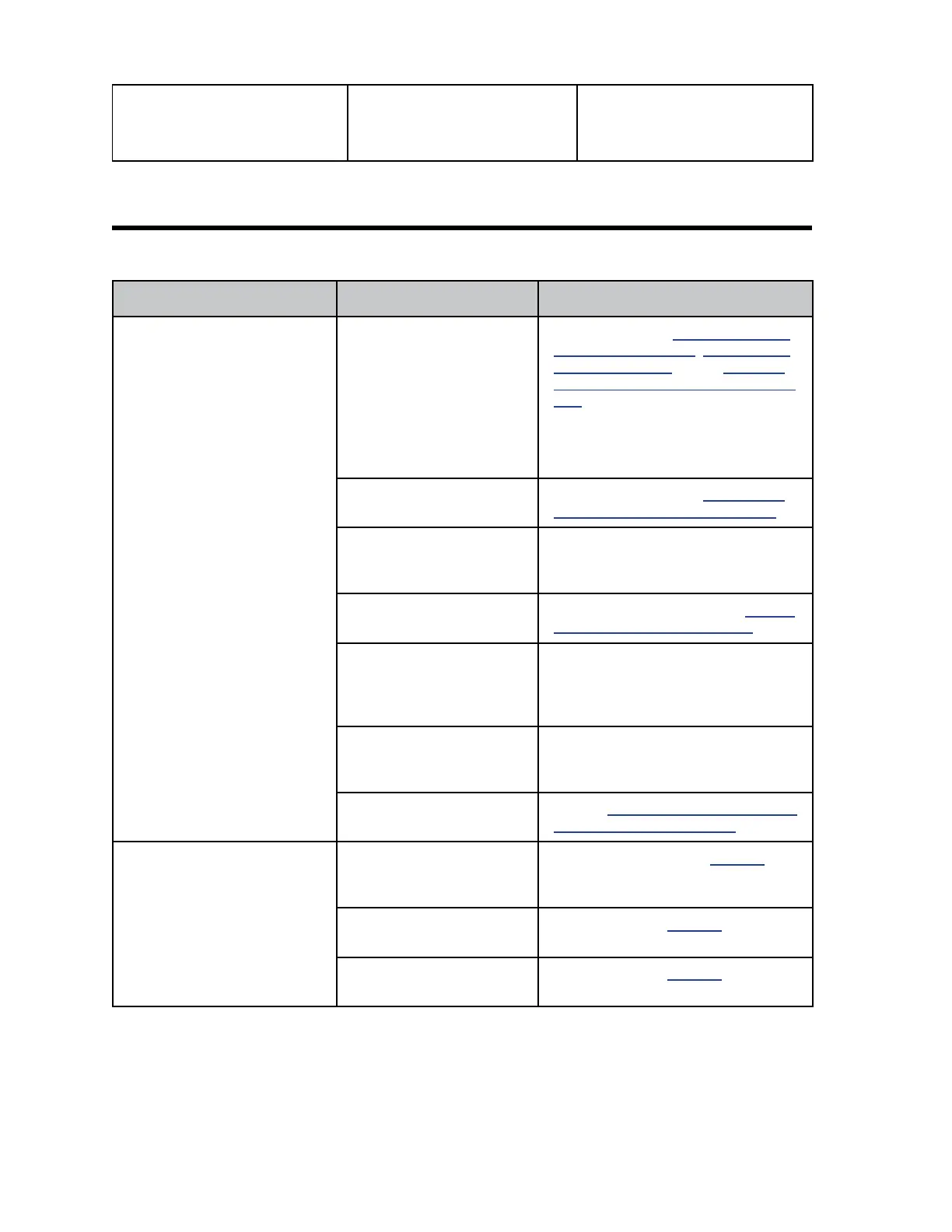

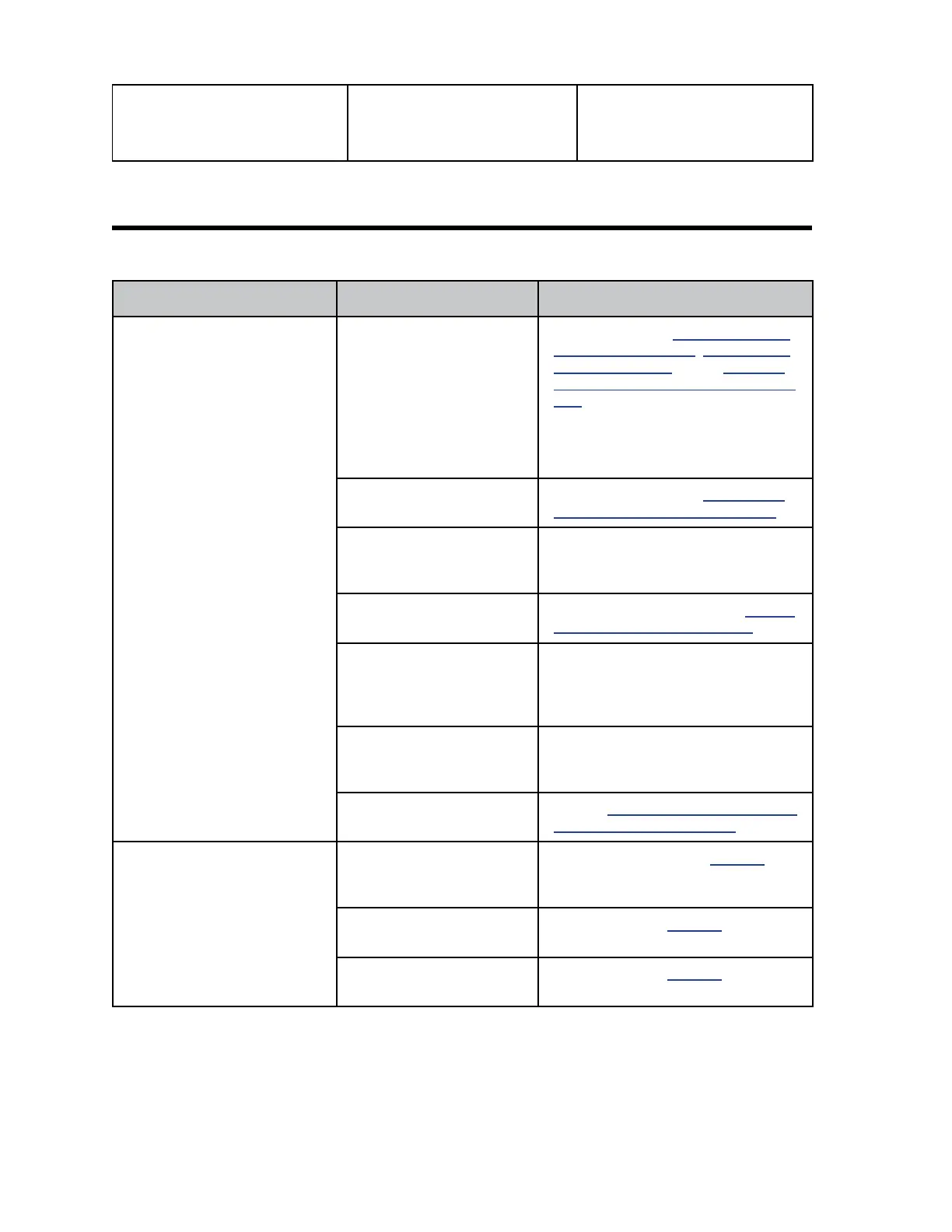

6.2 Mechanical System

ISSUE POSSIBLE CAUSE SOLUTION

Noisy Operation

1. Mechanical components

need lubrication.

• Lubricate. Refer to Grease “Weekly”

Bearings on page 4-8, Grease Bear-

ings on page 4-14, and/or Oil Drive

Chain and Tension Springs on page

4-14.

• Replace any bearing that does not

operate smoothly and quietly after being

lubricated.

2. Drive chain is loose.

• Adjust tension. Refer to Drive Chain

Tension Adjustment on page 7-23.

3. Sprockets are loose, worn,

or misaligned, or the drive

chain has excessive play.

• Inspect the sprockets and the drive

chain. Repair/replace as necessary.

4. Howling and whistling occur

when the burner is on.

• Clean the burner tips. Refer to Burner

Tip Maintenance on page 7-32.

5. Burner tail pipe clearance is

insucient.

• Check the burner tail pipe clearance

inside hollow drive shaft of ironing

cylinder. Reposition tail pipe holder, if

necessary.

6. Inverter frequency setting is

causing noisy motor opera-

tion.

• Adjust frequency. For more information,

contact the factory Service Department.

7. Drive train system error.

• Refer to Drive System Mechanical or

Electrical Error on page 6-8.

Ribbons Do Not Track Straight

1. Ribbon tension needs to be

adjusted.

• Adjust/Replace. Refer to REPAIR and

the appropriate section for the specic

procedure.

2. Ribbons are broken or

missing.

• Replace. Refer to REPAIR and the ap-

propriate section for specic procedure.

3. Roll friction material is

worn smooth.

• Replace. Refer to REPAIR and the ap-

propriate section for specic procedure.

Loading...

Loading...