Preventive Maintenance Comet Executive Gas

4-8

Grease “Weekly” Bearings

The grease ttings for the ironing cylinder

bearing (Figure 4-3, A) in the right endframe,

cam follower bearings (Figure 4-4, A) in the left

endframe, and compression roll bearings (Figure

4-3, B; Figure 4-4 B) in both endframes, are

marked with yellow “GREASE WEEKLY” tags

and need to be greased weekly.

Other bearings that are identied with the

yellow “GREASE” tags should also be greased

weekly if the unit is continuously run for long

periods.

A special high temperature lubricant is

required to properly grease all bearings. It is

important that only an EP, bentonite clay, NLGI

2, 1000 cSt viscosity grease be used.

Use of unsuitable grease can cause bearing

lockup or failure. Problems can also result if the

new grease is incompatible with the grease that

is already in the bearings.

Failure to use the correct lubricant will void

the factory warranty.

CAUTION

Before using a grease

other than specied, check

with the factory service

department to verify that

the grease meets

specications and is

compatible with the grease

already in the bearings.

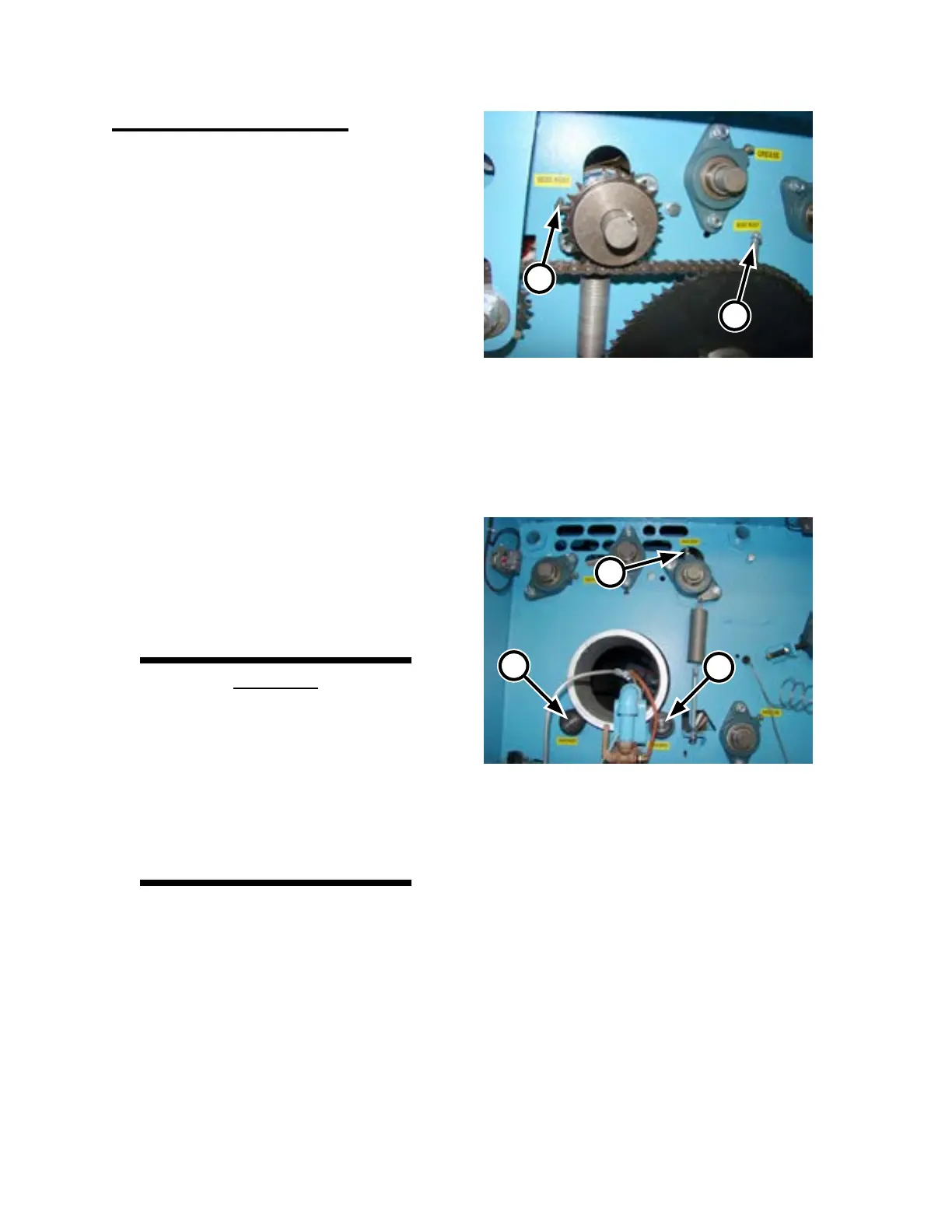

Figure 4-4: Add grease weekly to the ttings on

the cam follower bearings in the left

endframe.

A

B

A

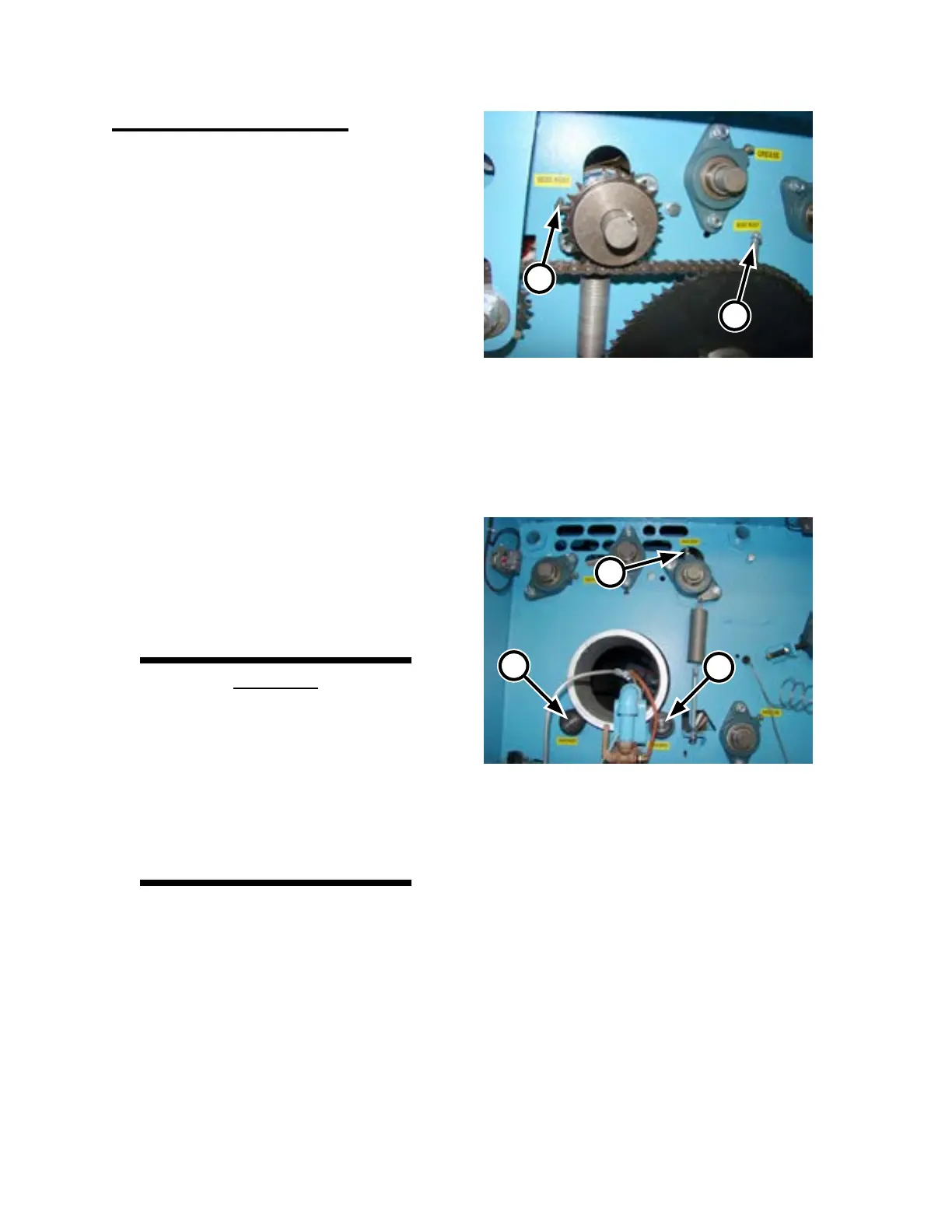

Figure 4-3: Add grease weekly to the tting for

the ironing cylinder bearing in the

right endframe and to the ttings for

the compression roll bearing in each

endframe.

A

B

Loading...

Loading...