Repair Comet Executive Gas

7-16

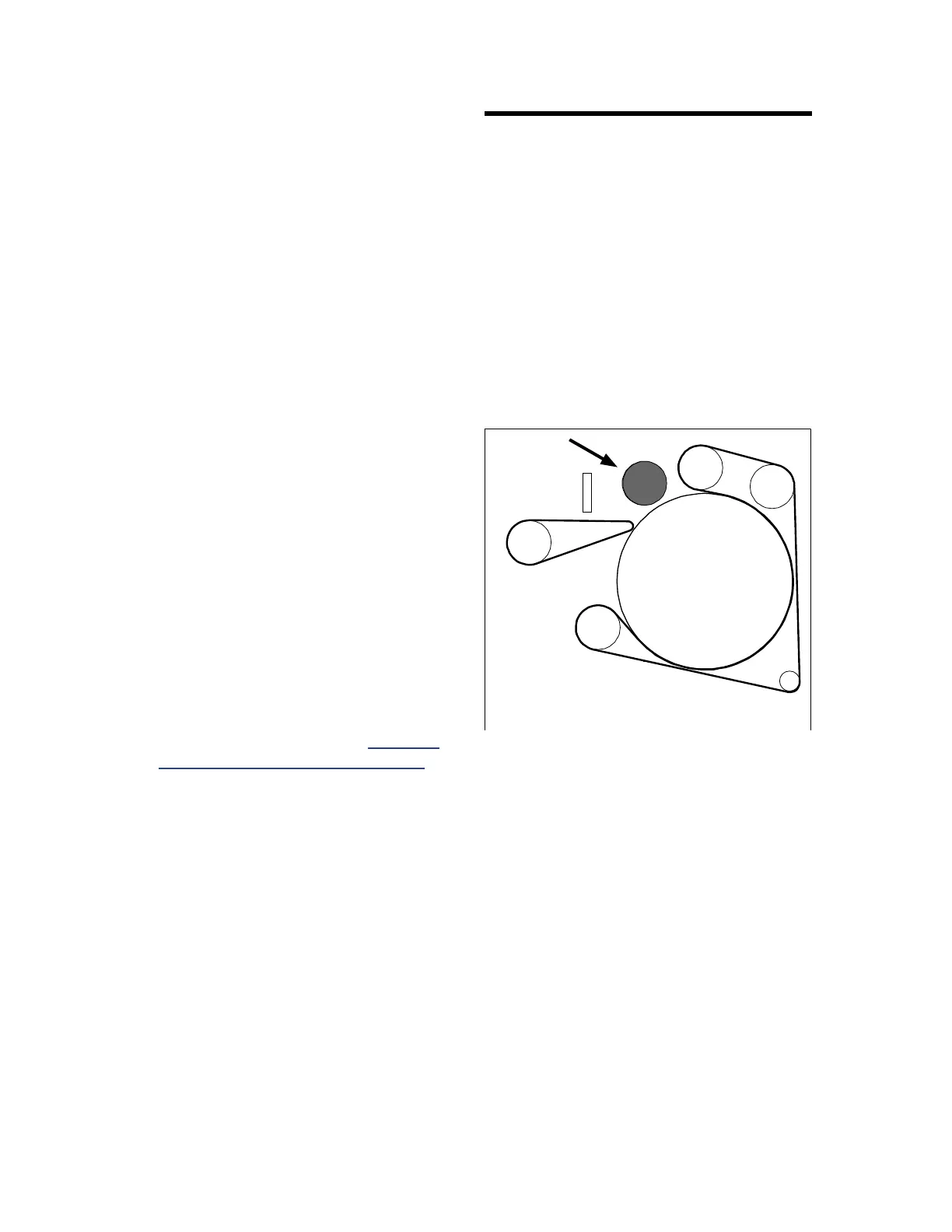

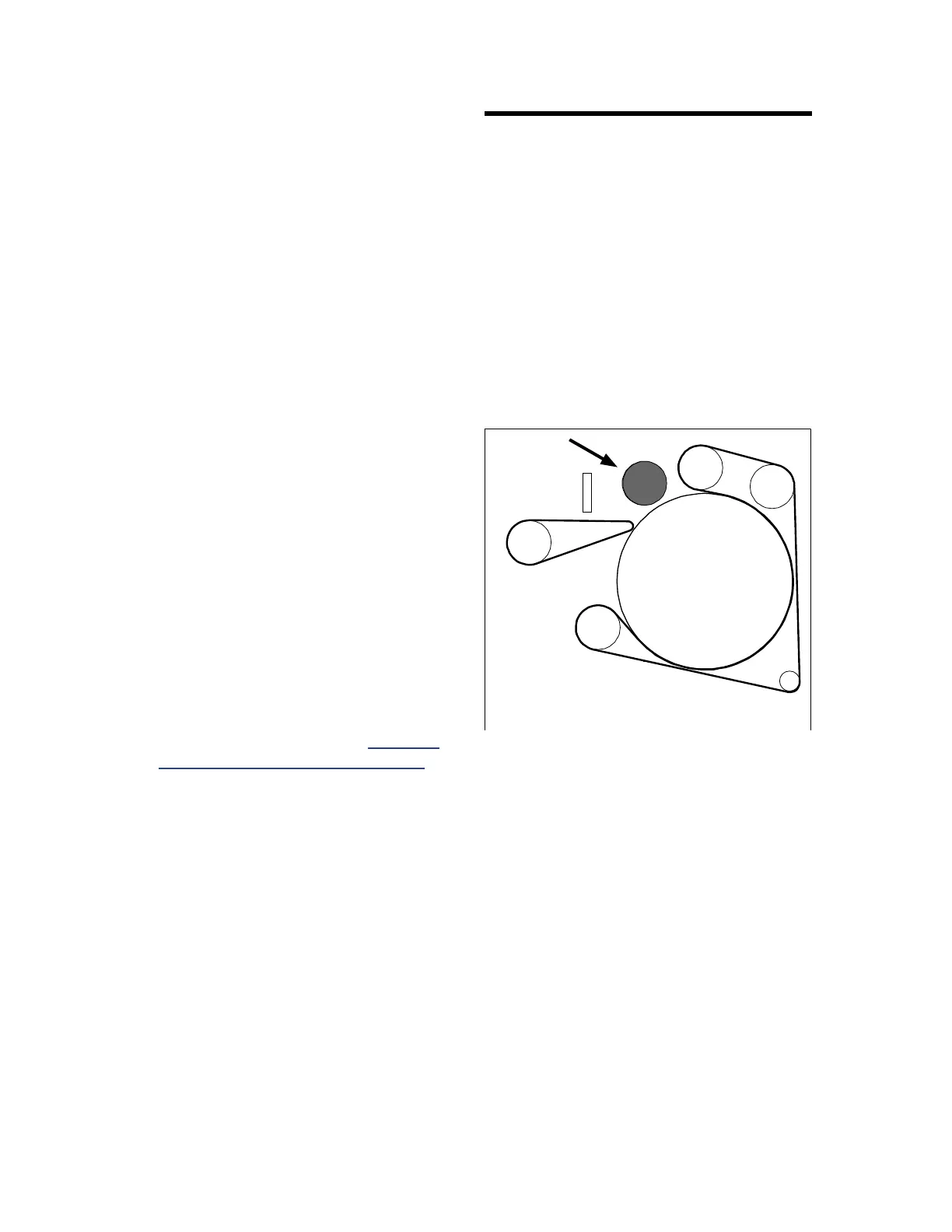

Figure 7-14: The compression roll helps to move the

atwork into the ironing section.

3. Repeat Steps 1 and 2 at the other end of

the unit.

4. Make sure the spacing at each end of the

unit is 1/4” (6 mm) and the bolts in the

slotted holes are securely tightened.

5. Check the spacing between the feed table

and the ironing cylinder at the center of the

unit. The correct spacing is 3/8”.

• If the spacing is less than 3/8”

(9 mm), tighten the nuts equally on

each side of the tension adjustment

rod (Figure 7-13, B) until the middle

of the feed table is 3/8” from the iron-

ing cylinder.

• If the spacing is more than 3/8”

(9 mm), loosen the nuts equally on each

side of the tension adjustment rod (Fig-

ure 7-13, B) until the middle of the feed

table is 3/8” from the ironing cylinder.

6. Reconnect the feed ribbons. Make sure the

ribbons are below the tension adjustment

rod, and also below and between the feed

ribbon guides.

7. Stagger the positions of the lacing clips to

give atwork a smooth ow.

8. Adjust ribbon tension; refer to Feed Rib-

bon Tension Adjustment on page 7-5.

7.4 Compression Roll

The compression roll (Figure 7-14) improves

flatwork finish. Some of compression roll

components require periodic adjustment,

replacement or occasional repair.

These procedures include:

• Compression Roll Pressure Check

• Compression Roll Pressure Adjustment

• Compression Roll Cover Replacement

Loading...

Loading...