SECTION - 6 DRIVE SYSTEM AND ENGINE INSTALLATION

90-899883183 DECEMBER 2007 Page 31 / 54

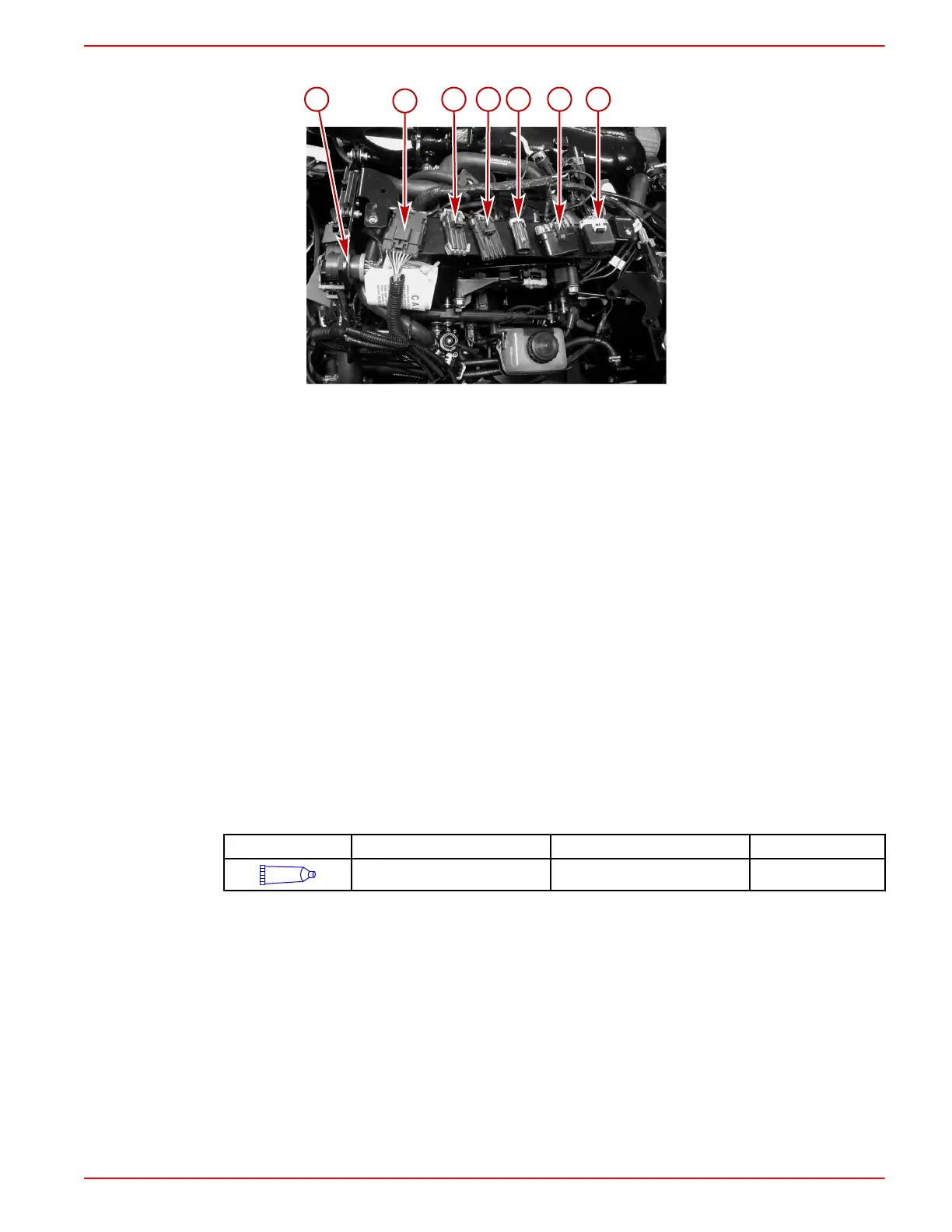

3. Connect the following:

a - 14‑pin harness connector

b - Transom harness connector

c - Paddle wheel and tank level

connector

d - Diagnostic connector

e - Power harness connector

f - Fuses

g - Fuses

CONTINUITY WIRE CONNECTION

IMPORTANT: The transom continuity circut is incorporated into the transom harness.

Electrical Connections

NOTE: Refer to Section 7 for additional electrical information.

To avoid damage to the electrical system, observe the following when working on or around the

electrical harness, or when adding other electrical accessories:

• Do not icorporate accessories into the engine harness.

• Do not probe or puncture wires for testing.

• Do not reverse the battery leads.

• Do not splice wires into the harness.

• Do not attempt diagnostics without the proper, approved service tools.

IMPORTANT: Route and secure all wires and hoses to avoid contact with hot spots and moving

parts.

Tube Ref No. Description Where Used Part No.

25

Liquid Neoprene All electrical connections 92- 25711 3

INSTRUMENTATION CONNECTIONS

We recommend using Quicksilver Instrumentation and Wiring Harnesses. On dual station

applications, oil pressure and water temperature senders on the engine must be changed. Refer

to the appropriate Mercury Precision Parts Accessories Guide for assistance.

The four basic gauges that must be used with the engine are:

• Tachometer

• Oil pressure

• Water temperature

• Voltmeter

NOTE: An accessory kit is available to provide accessory power up to 40 amps.

Loading...

Loading...