SECTION - 6 DRIVE SYSTEM AND ENGINE INSTALLATION

90-899883183 DECEMBER 2007 Page 51 / 54

Alpha Trim Cylinder Reassembly

!

CAUTION

Contamination can damage the hydraulic system or cause the system to malfunction. Failure of

power trim or steering components can result in injury or product damage. Ensure that the work

area, shop tools and all components are clean and lint free during reassembly.

1. Apply sealant to threads of shock piston bolt.

Tube Ref No. Description Where Used Part No.

7

Loctite 271 Threadlocker Trim cylinder bolt threads 92-809819

2. Install washer and bolt and torque.

Description Nm lb. in. lb. ft.

Trim cylinder shock piston bolt 23 17

IMPORTANT: During service procedures, clamp the trim cylinder on the front mounting flange.

Clamping the center section of the trim cylinder can cause damage.

IMPORTANT: Use only 2‑4‑C with Teflon on the end cap threads. Other substances may act as

an insulator and cause poor electrical continuity between the cap and cylinder, which could

promote corrosion.

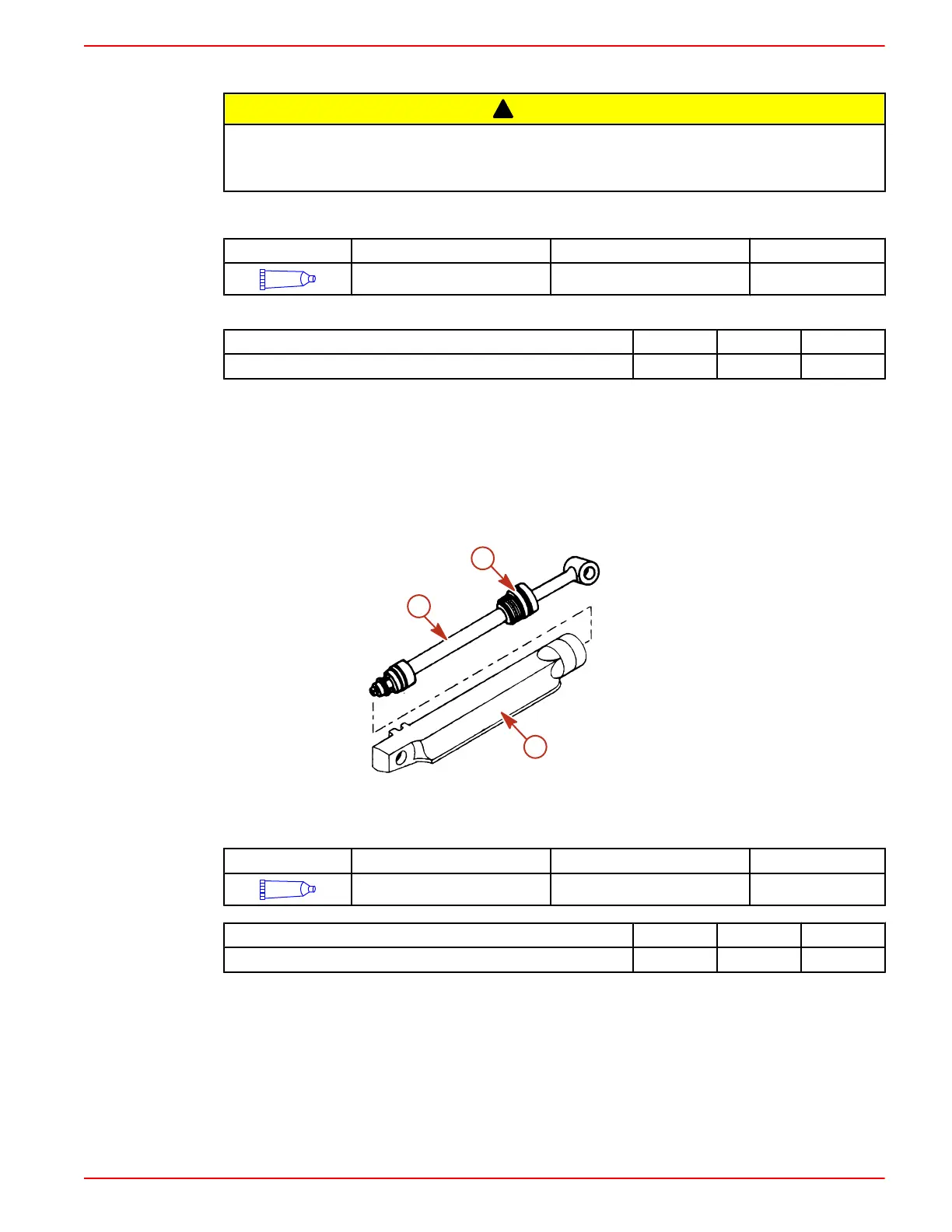

3. Apply lubricant to end cap threads and install piston rod assembly into cylinder.

4. Torque end cap using the spanner wrench.

c

b

a

7847

a - End cap

b - Piston rod assembly

c - Cylinder

Tube Ref No. Description Where Used Part No.

34

Special Lubricant 101 Trim cylinder end cap 92-802865Q02

Description Nm lb. in. lb. ft.

Trim cylinder end cap 61 45

Loading...

Loading...