TIMING, SYNCHRONIZING & ADJUSTING

Page 2C-4 90-855347R1 JANUARY 1999

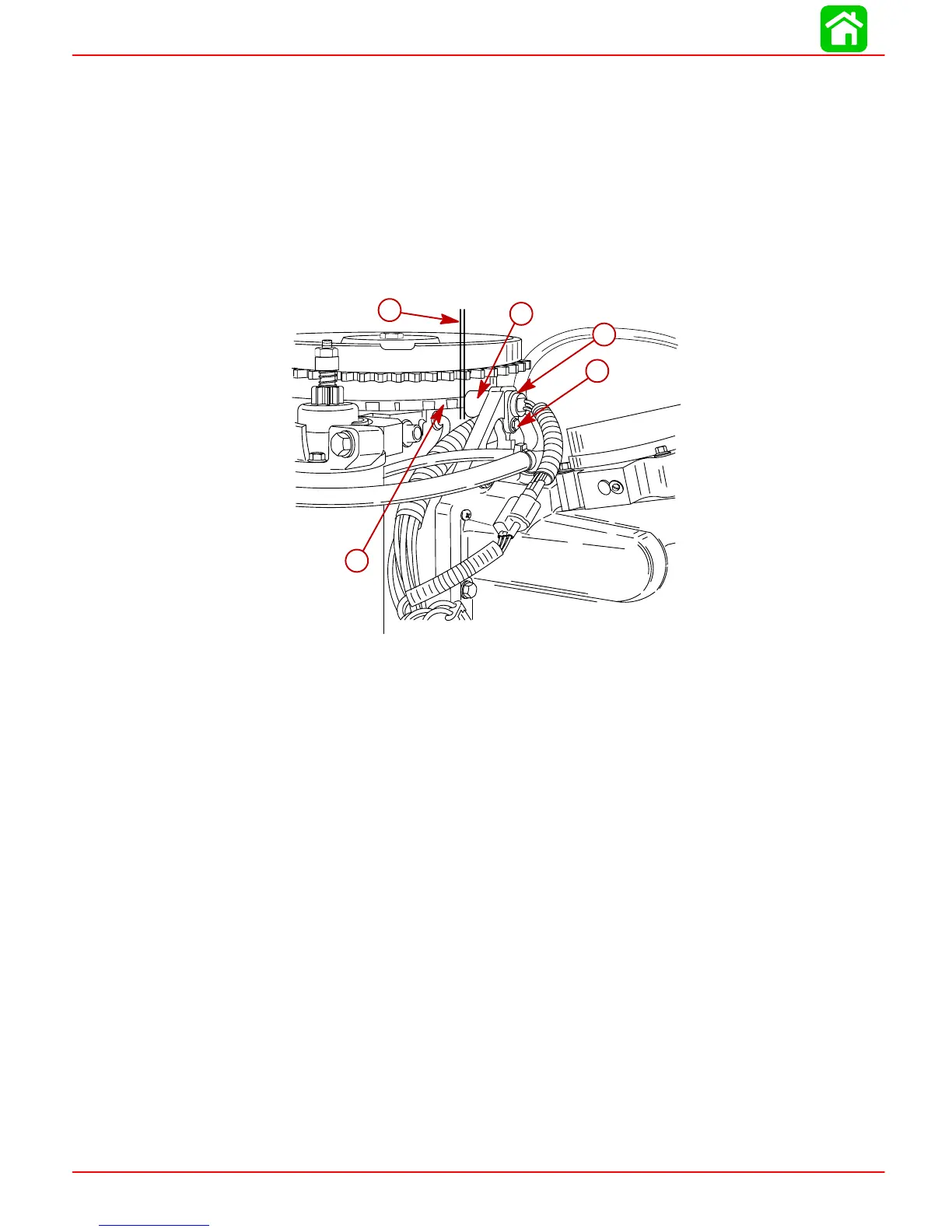

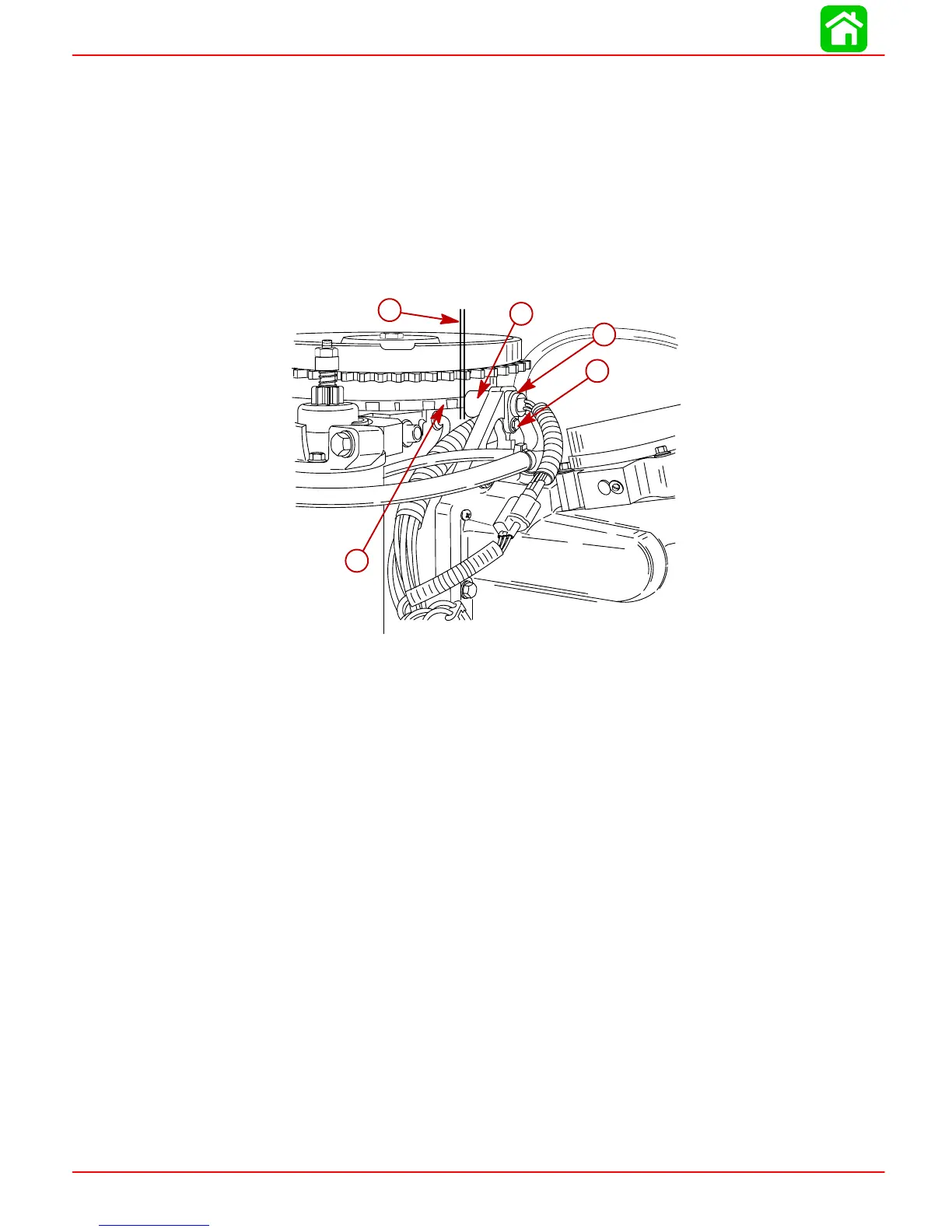

Crank Position Sensor

NOTE: Crank Position Sensor is normally not adjustable, but shims are available if sensor

is found to be to close to flywheel.

1. Remove flywheel cover.

2. Using a feeler gauge, measure the air gap between the crank position sensor and a

tooth on the flywheel. Gap should be 0.025 in. - 0.040 in. (0.635 mm - 1.02 mm).

IMPORTANT: Crank Position Sensor must be perpendicular to flywheel tooth.

3. Reinstall flywheel cover.

d

c

56069

a

c

d

b

e

a-Air Gap [0.025 in - 0.040 in.(0.635 mm - 1.02 mm)]

b-Crank Position Sensor

c-Flywheel Tooth

d-Bracket Screw (Drive Tight)

e-0.010 in. (0.254 mm) or 0.020 in. (0.508 mm) Shim if required – refer to parts

manual

Loading...

Loading...