CHARGING & STARTING SYSTEM

Page 2B-18 90-855347R1 JANUARY 1999

IMPORTANT: The regulator, rectifier and brush assembly are the only components

individually replaceable on this alternator. If the rotor or stator is defective, the en-

tire rotor, stator and housing must be replaced as an assembly.

IMPORTANT: Clean anti-corrosion paint from electrical connections prior to reas-

sembly. Coat all electrical connections with LIQUID NEOPRENE (92-25711-1).

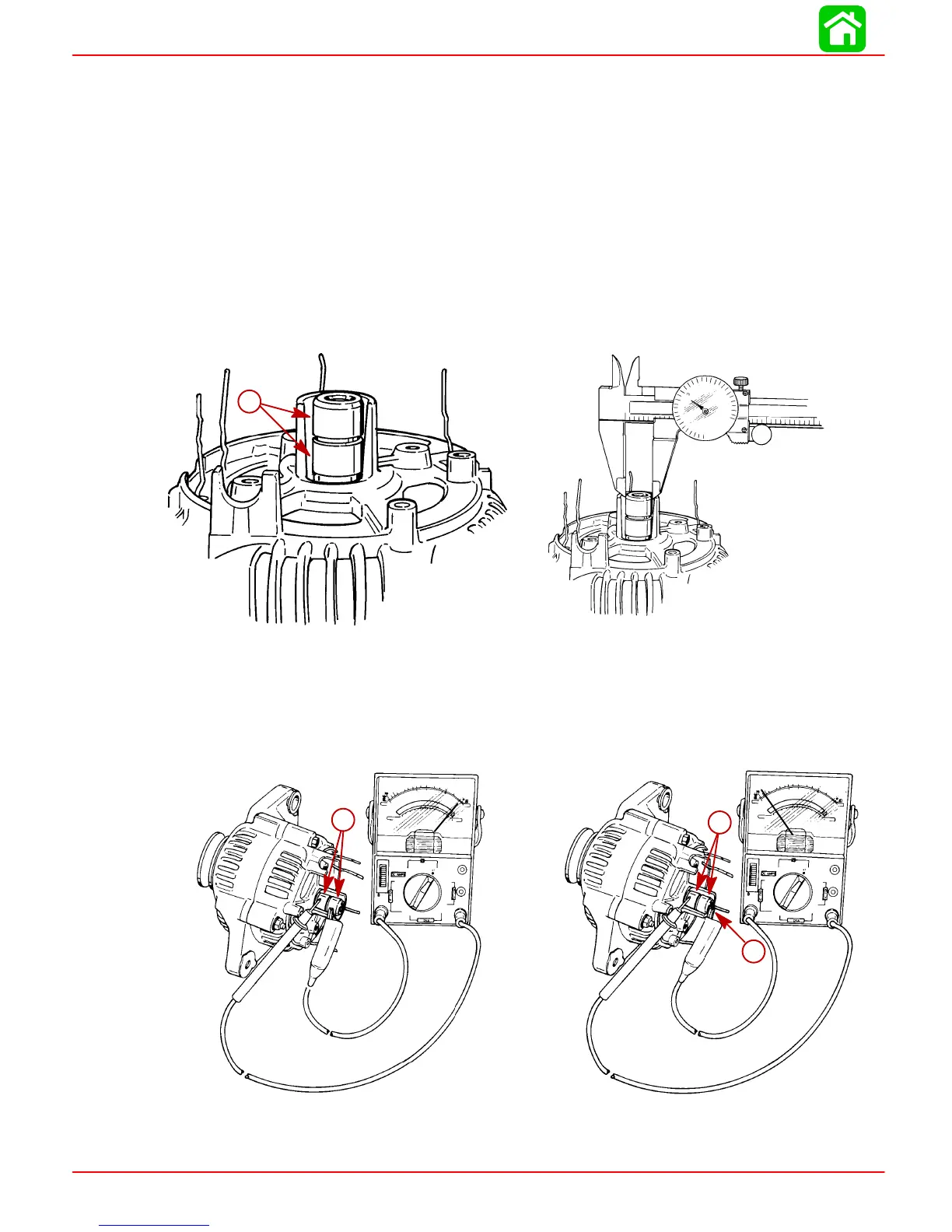

Rotor Test

1. Inspect slip ring surface for roughness, abnormal wear and/or burning. If such condi-

tions exist, rotor is not considered serviceable and alternator should be replaced.

2. Measure the outer diameter of the slip rings using vernier calipers. STANDARD DI-

AMETER: 0.567 in. (14.4 mm); MINIMUM DIAMETER: 0.551 in. (14 mm). If slip ring

diameter is less than minimum, rotor is not considered serviceable and alternator

should be replaced.

51680

51684

a

a

a-Slip Rings

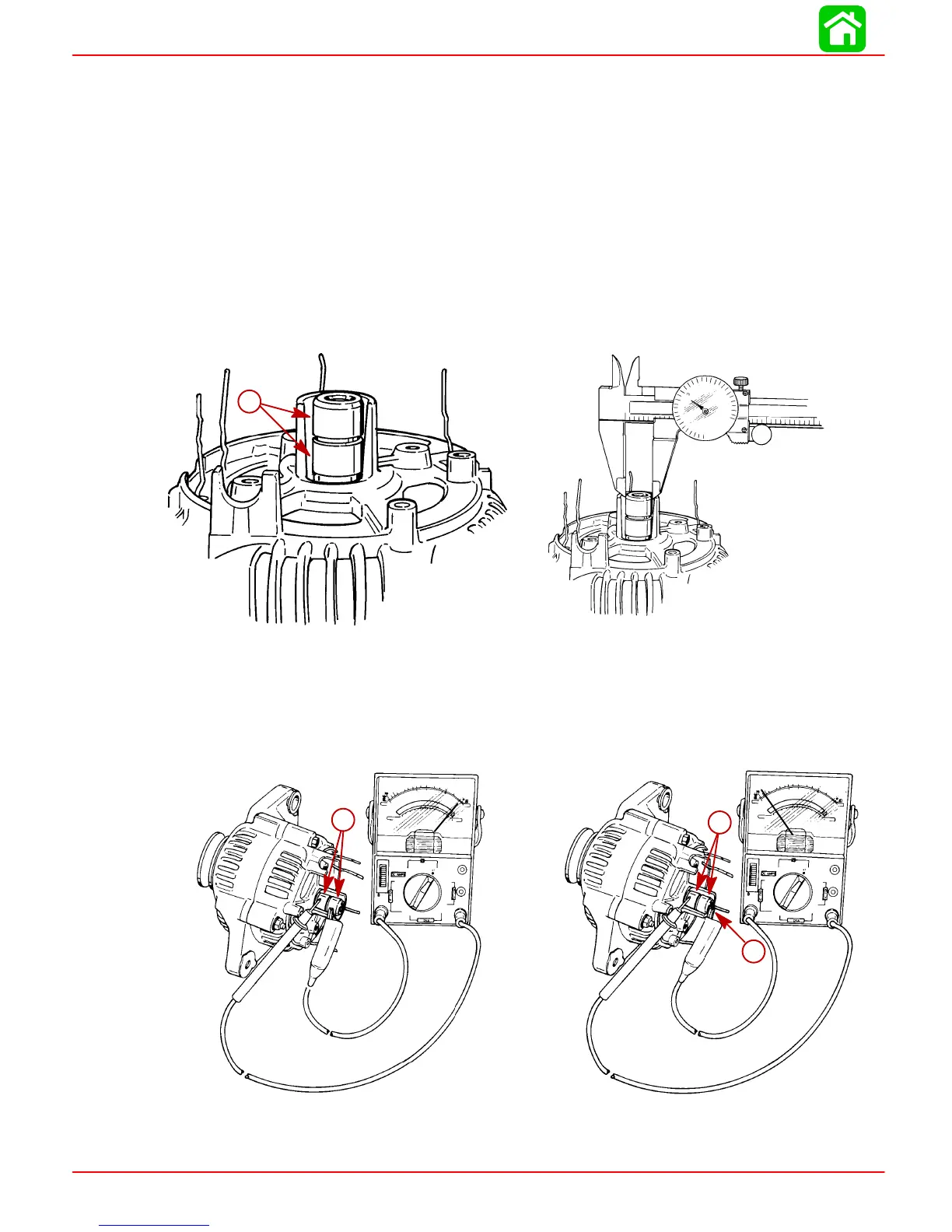

3. Inspect rotor for an open circuit. Using an ohmmeter, check for continuity between slip

rings. Resistance should not exceed 3 ohms. If no continuity exists, rotor is defective.

4. Check rotor for short to ground. NO CONTINUITY should exist between slip rings and

rotor shaft. If CONTINUITY exists, rotor is defective.

51683

a

b

51682

a

a

a

b

a-Slip Rings

b-Rotor Shaft

Loading...

Loading...