CHARGING & STARTING SYSTEM

90-855347R1 JANUARY 1999 Page 2B-5

2. When adding distilled water to battery, be extremely careful not to fill more than 3/16

in. (4.8 mm) above perforated baffles inside battery. Battery solution or electrolyte ex-

pands from heat caused by charging. Overfilling battery will cause electrolyte to over-

flow (if filled beyond 3/16″ above baffles).

3. Grease terminal bolts well with 2-4-C Marine Lubricant and store battery in a COOL-

DRY place. Remove battery from storage every 30-45 days, check water level and

put on charge for 5 or 6 hours at 6 amperes. DO NOT FAST CHARGE.

4. If specific gravity drops below 1.240, check battery for reason and recharge. When

gravity reaches 1.260, discontinue charging. To check specific gravity, use a hydrom-

eter, which can be purchased locally.

5. Repeat preceding charging procedure every 30-45 days, as long as battery is in stor-

age, for best possible maintenance during inactive periods to ensure a good service-

able battery in spring. When ready to place battery back in service, remove excess

grease from terminals (a small amount is desirable on terminals at all times), recharge

again as necessary and reinstall battery.

Flywheel Removal and Installation

Removal

1. Remove flywheel cover from engine.

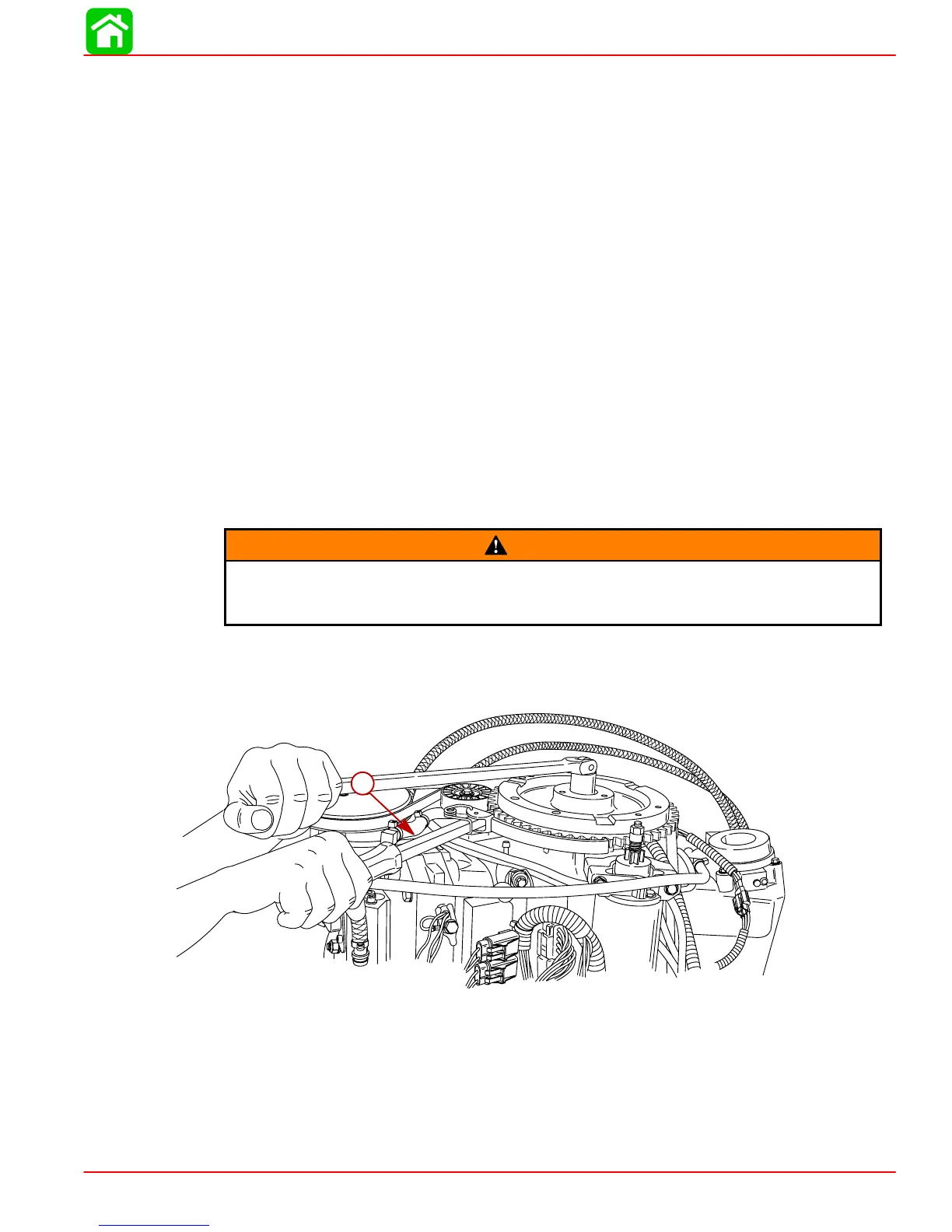

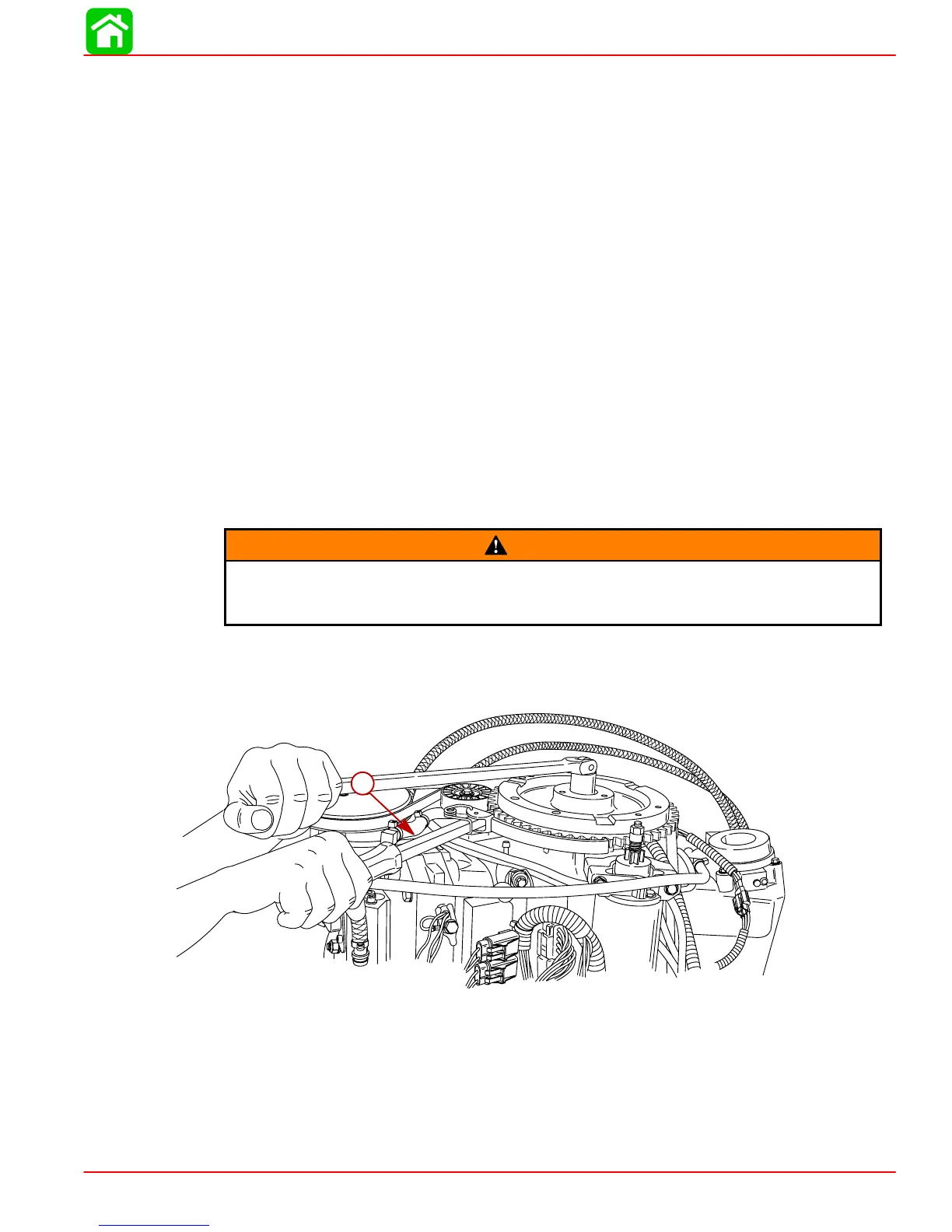

WARNING

Engine could possibly start when turning flywheel during removal and installa-

tion; therefore, disconnect (and isolate) spark plug leads from spark plugs to pre-

vent engine from starting.

2. Disconnect spark plug leads from spark plugs.

3. While holding flywheel with flywheel holder (91-52344), remove flywheel nut and

washer.

57415

a

a-Flywheel Holder (91-25344)

4. Install a crankshaft Protector Cap (91-24161) on end of crankshaft, then install Fly-

wheel Puller (91-73687A2) into flywheel.

Loading...

Loading...