DIRECT FUEL INJECTION

Page 3B-20 90-855347R1 JANUARY 1999

Compressor Notes: To aid in starting when the air rail pressure is low and before the

compressor has time to build pressure, the direct injector is held open by the ECM. This

allows the compression from inside the cylinders to pressurize the air rail faster (1 or 2

strokes, or 60

0

of crankshaft rotation).

Idle Notes: Idle quality is controlled by fuel volume and fuel timing. The throttle shutters

will be open at idle speeds. The shift cut-out switch will interrupt the fuel to 3 of the cylin-

ders to assist in shifting.

The TPS signals the ECM to change the fuel and spark without movement of the throttle

shutters. The throttle cam is manufactured to allow the TPS sensor shaft to move before

opening the throttle shutters.

The crankshaft position sensor is different from the standard 3.0 liter sensor. The crank

position sensor serves two functions (flywheel speed and position).

Testing Electric Fuel Pump Pressure Output

Low Pressure Electric Fuel Pump

IMPORTANT: After completing fuel pressure tests, reconnect and secure fuel outlet

hose to fuel pump with full circle stainless clamps in Clamp Tool Kit 91-803146T.

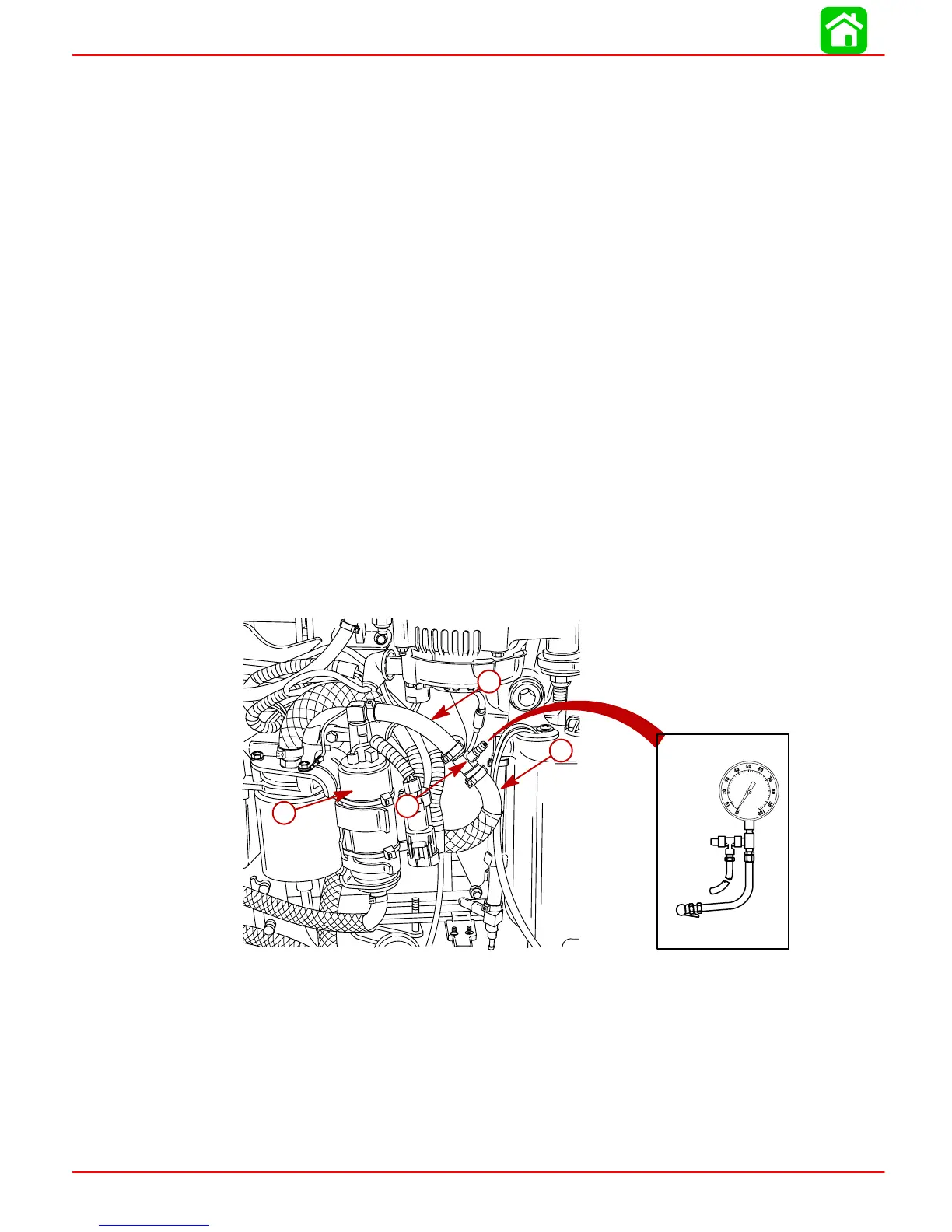

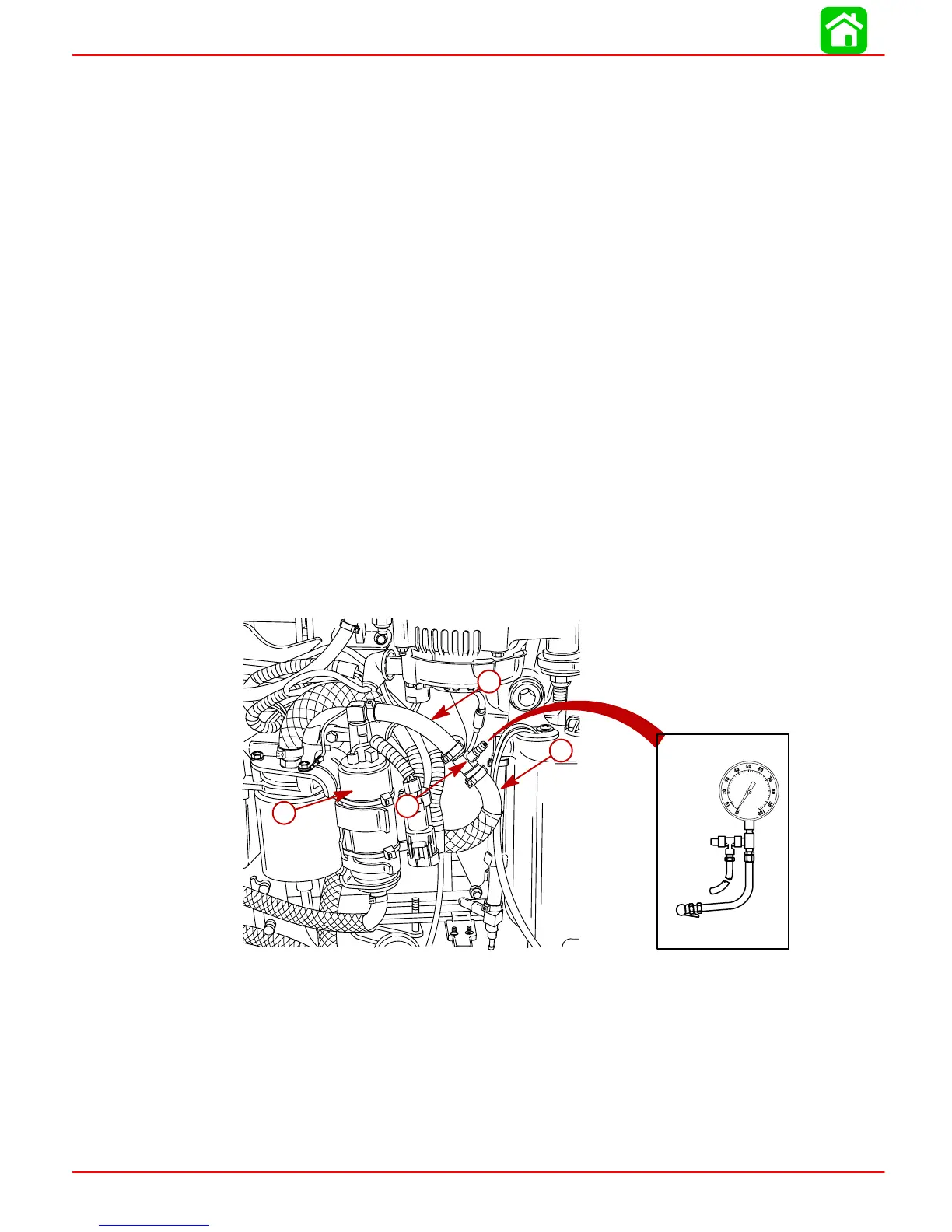

1. Remove outlet fuel hose from low pressure pump. Install a short piece of hose (obtain

locally) onto pump outlet fitting. Install Schrader Valve t-fitting (22-849606) from

Schrader Valve Fuel Pressure Kit (849021A4) between outlet fuel hose (removed

from pump) and new fuel hose (installed on pump. Secure hose connections with sta-

straps. Connect Fuel/Air Pressure Gauge (91-16850A2) to Schrader Valve. Gauge

should indicate 6-9 psi (41.37 – 62.04 kPa).

57416

a

b

c

91-16850A2

d

a-Outlet Fuel Hose

b-Low Pressure Electric Fuel Pump

c-Fuel Hose (obtain locally)

d-Schrader Valve (22-849606)

Loading...

Loading...