IGNITION

Page 2A-16 90-855347R1 JANUARY 1999

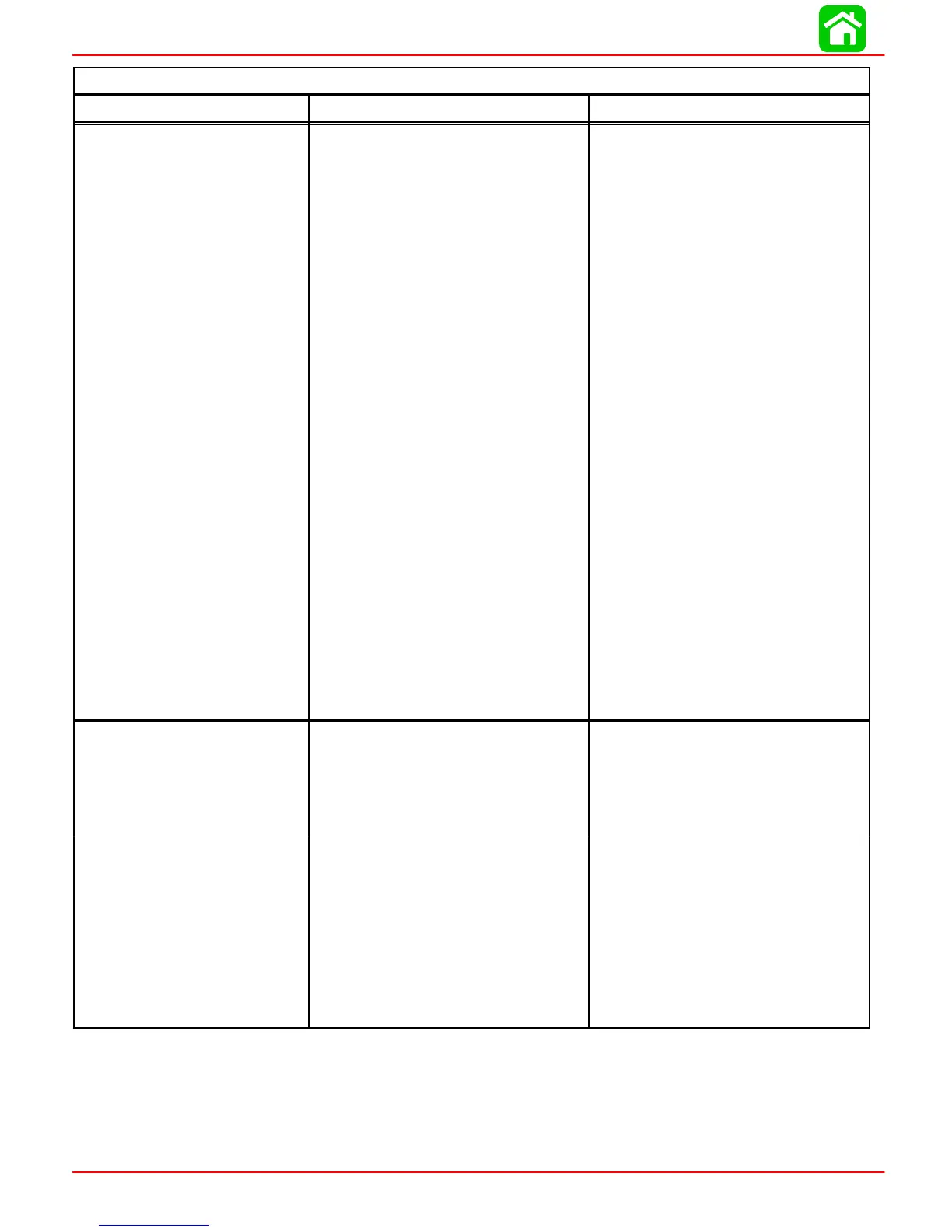

DFI Troubleshooting Guide (continued)

Symptom Cause Action

1. Engine cranks but will not

start (continued)

1.9 ECM not functioning Injection System:

Listen for injector “ticking” when

cranking or connect spare injector

to each respective harness. Tick-

ing should start after 2 cranking

revolutions.

Ignition System:

– Check for proper operation by

using Inductive Timing Light

91-99379.

– Check battery voltage

(RED/YEL Lead) @ ignition

coils.

– Check for blown fuse (C15).

– Check battery voltage to fuse

from main power relay

(PURPLE Lead).

– Check for shorted stop wire

(BLK/YEL).

– Check crank position sensor

setting [0.015 in. – 0.040 in.

(0.38mm – 1.01mm)] from

flywheel or for defective crank

position sensor.

– Defective ECM.

Power Supply:

Clean and inspect remote control

male and female harness connec-

tors.

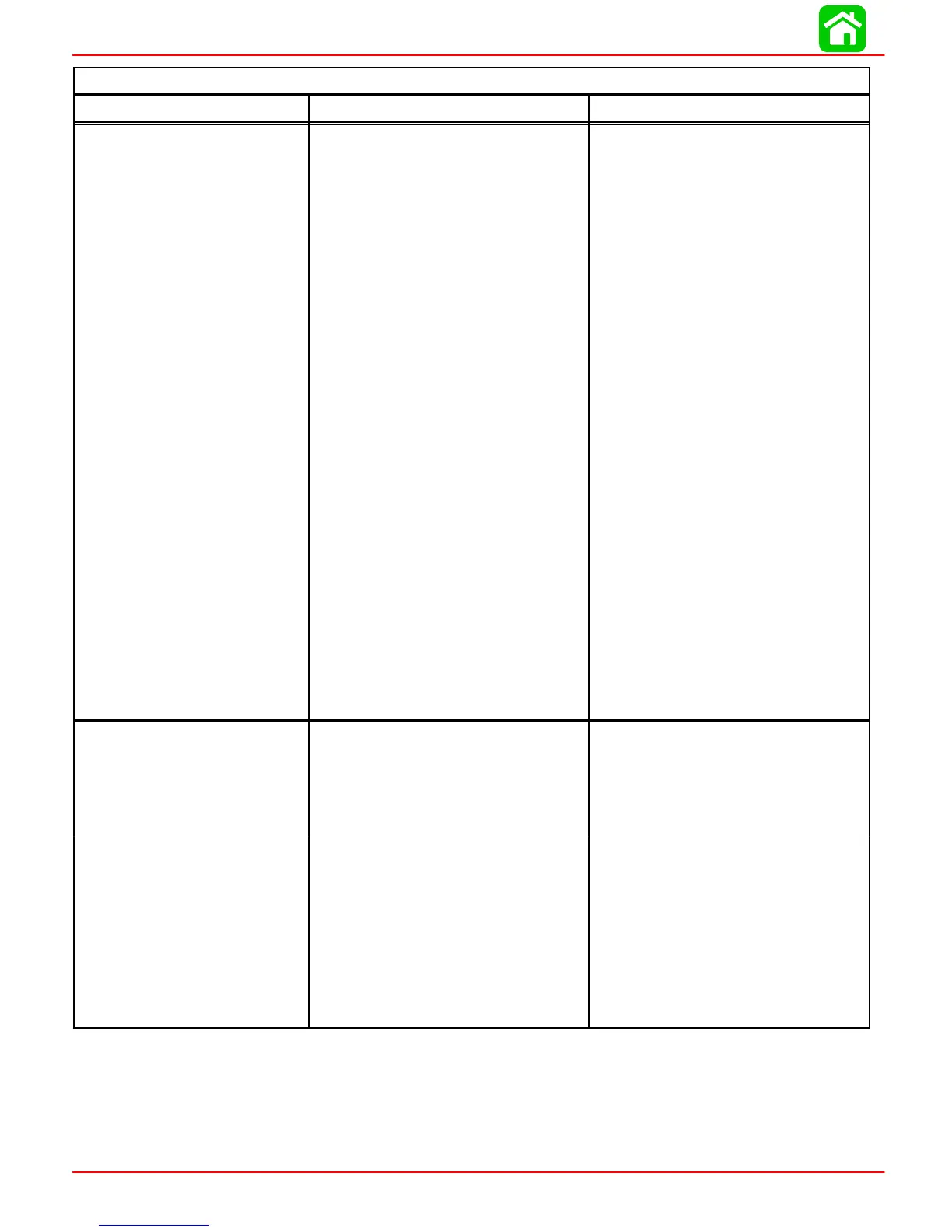

2. Engine cranks, starts and

stalls

2.0 Low air pressure in rail See 1.2

2.1 Low fuel pressure in rail See 1.2 and 1.3

2.2 Abnormally high friction in

engine

Check for scuffed piston or other

sources of high friction.

2.3 Air in fuel system/lines See 1.3 Crank and start engine

several times to purge.

2.4 TPS malfunction Check motion of throttle arm. Stop

nuts should contact block at idle

and WOT. Check TPS set-up. Must

connect DDT with adapter harness

(84-822560A5) to ECM.

2.5 Remote control to engine

harness connection is poor

Clean and inspect male and fe-

male connectors.

Loading...

Loading...