6 - ORDINARY MAINTENANCE

6 - 22

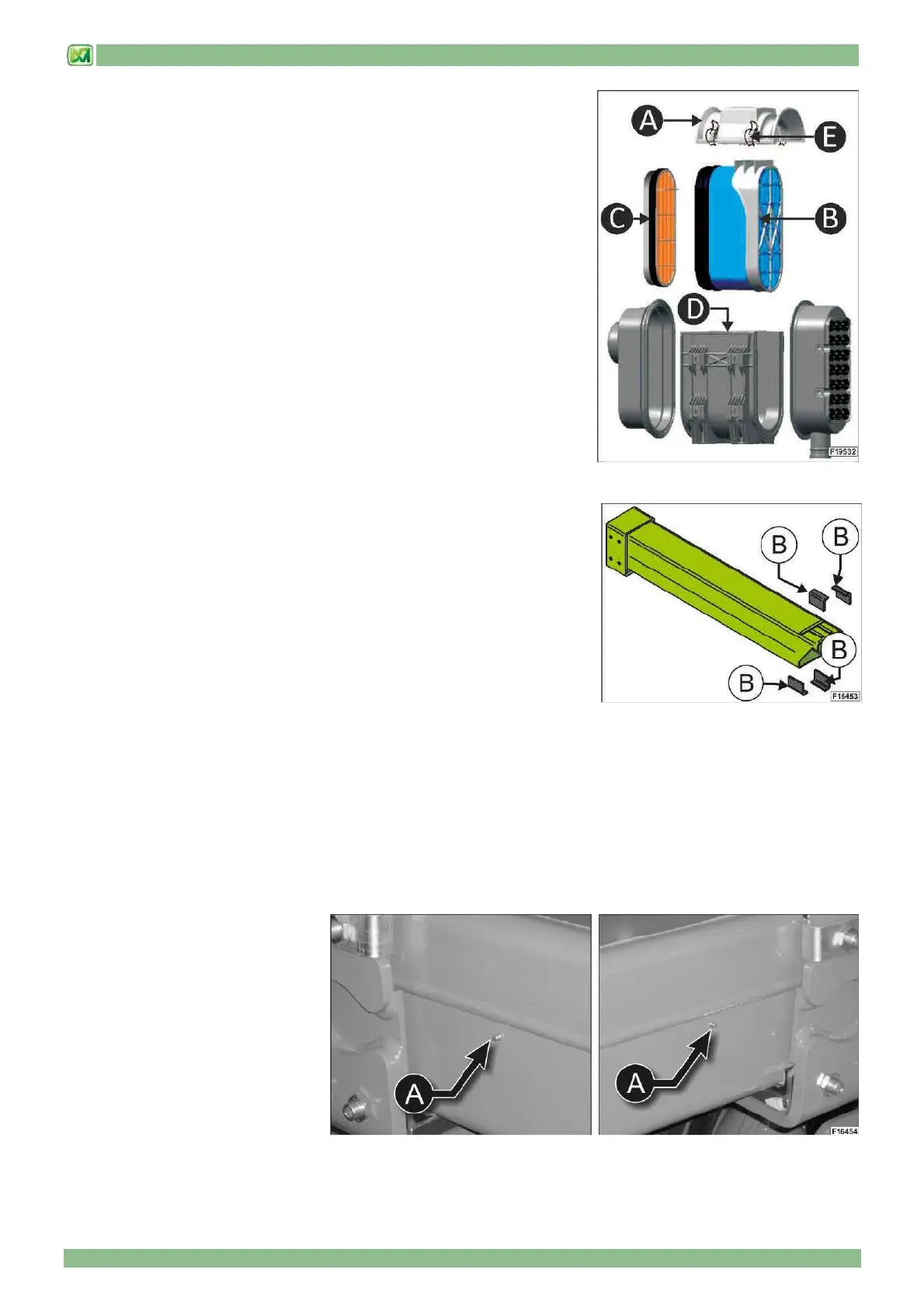

• ENGINE AIR FILTER

A) cover

B) locking device

C) filter cartridge

D) safety cartridge

E) filter body

- remove the filter cover by using the release devices (E)

- pull out the filter cartridge (B) from its seat

- pull out the safety cartridge (C) from its seat

- fit a new safety cartridge (C) in its seat

- fit a new filter cartridge (B) in its seat

- clean the inside of the filter body (D) and the cover (A).

- close the cover (A) using the specific clamping devices (E)

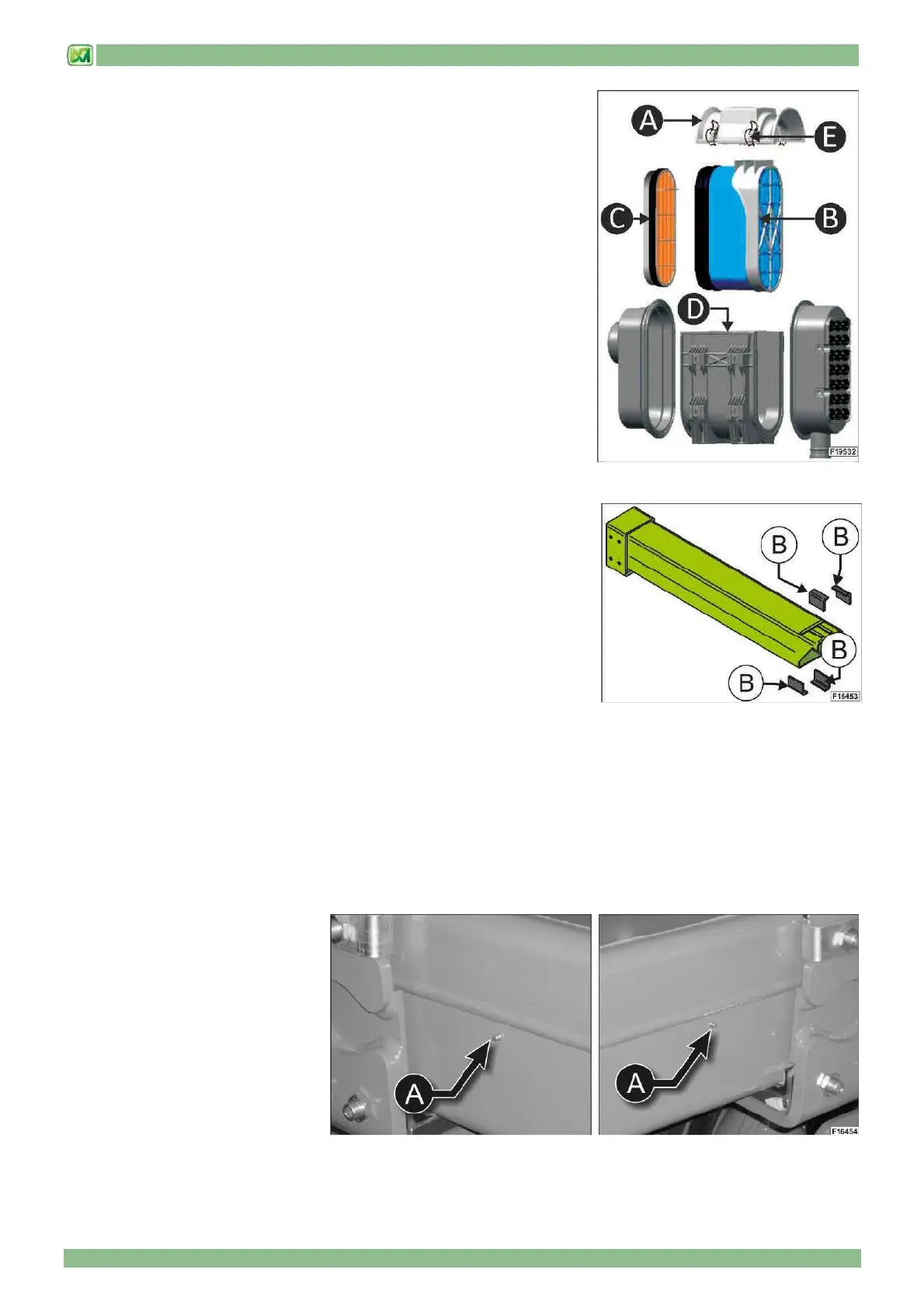

• SLIDING PADS OF THE TELESCOPIC BOOM (INNER PADS)

A visual inspection of the inner sliding pads "B" is necessary to ensure maximum

reliability, performance and durability of the telescopic boom.

To inspect the inner sliding pads of the telescopic boom, remove rear case "4"

first (see also paragraph "COVERS").

Perform the following checks on the inner sliding pads of the telescopic boom:

1 - visual inspection of inner sliding pads to check for wear

2 - visual inspection of inner sliding pads to check for wear uniformity

3 - visual inspection of inner sliding pads to check for any breaks

4 - visual inspection of inner sliding pads to check for any burrs or large shavings (plastic powder is accepted).

Should any of the above conditions occur, please contact Merlo Technical Assistance Service.

• SCREWS AND BOLTS

Check tightness. See torque chart in this manual (section MACHINE TECHNICAL INFORMATION). The nuts and bolts control

instructions of some machine parts are indicated in the paragraph RUNNING-IN PERIOD.

• PIPELINE GUIDE PIPE

(only for models P40.9 PLUS –

P60.10 – P72.10 – P60.10EE –

P72.10EE)

Completely extend the boom and

grease (about 200 cc) in the points

shown (A).

Loading...

Loading...