2 - MACHINE TECHNICAL INFORMATION

2 - 30

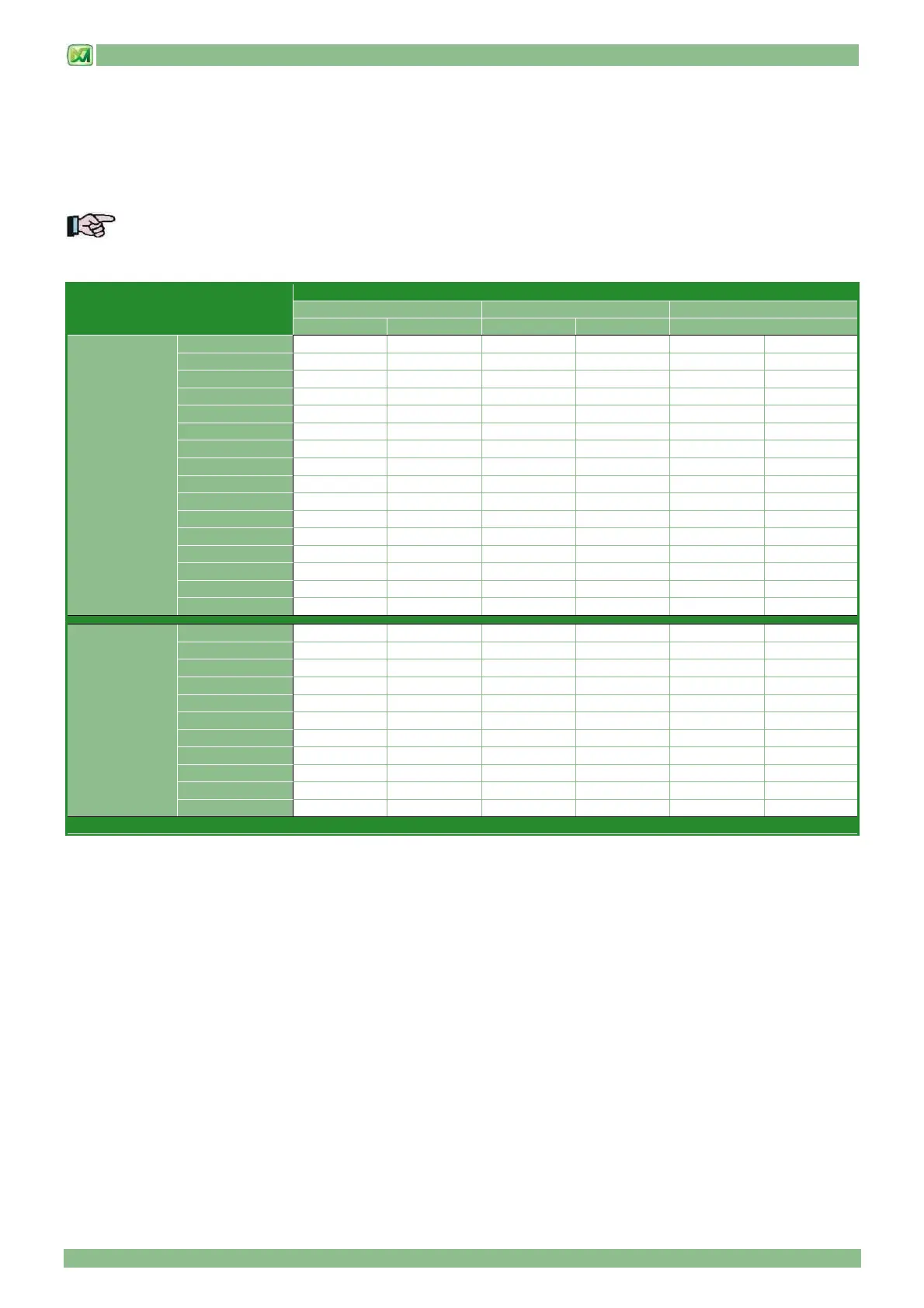

TIGHTENING TORQUES FOR ISO METRIC THREADS

The tightening torque "Ma" of either a screw or a nut is the moment of a force required to put the screw under a certain initial

tension. The tightening torque value is used to adjust the dynamometric wrench, as well as to prevent the screw from breaking

due to fatigue. The following table shows the tightening torques "Ma" related to the external diameters of screws having metric

threads. These are just indicative values, because the exact values depend on both the friction and the machining conditions of

the screw supporting surfaces.

NOTE!

This table refers to a slowly applied tightening and with dynamometric cables.

SIZE OF BOLT

TYPE OF BOLT

8.8 10.9 12.9

Nm Kgm Nm Kgm Nm Kgm

COARSE

PITCH

M3 x 0.5

1.8 0.18 2.6 0.27 3 0.31

M4 x 0.7

3.1 0.32 4.5 0.46 5.3 0.54

M5 x 0.8

6.1 0.62 8.9 0.91 10.4 1.06

M6 x 1

10.4 1.06 15.3 1.56 17.9 1.82

M7 x 1

17.2 1.75 25 2.55 30 3.06

M8 x 1.25

25 2.55 37 3.77 44 4.49

M10 x 1.5

50 5.10 73 7.44 86 8.77

M12 x 1.75

86 8.77 127 12.95 148 15.09

M14 x 2

137 13.97 201 20.49 235 23.96

M16 x 2

214 21.81 314 32.01 368 37.51

M18 x 2.5

306 31.19 435 44.34 509 51.89

M20 x 2.5

432 44.04 615 62.69 719 73.29

M22 x 2.5

592 60.35 843 85.93 987 100.61

M24 x 3

744 75.84 1060 108.05 1240 126.4

M27 x 3

1100 112.13 1570 160.04 1840 187.56

M30 x 3.5

1500 152.91 2130 217.13 2500 254.84

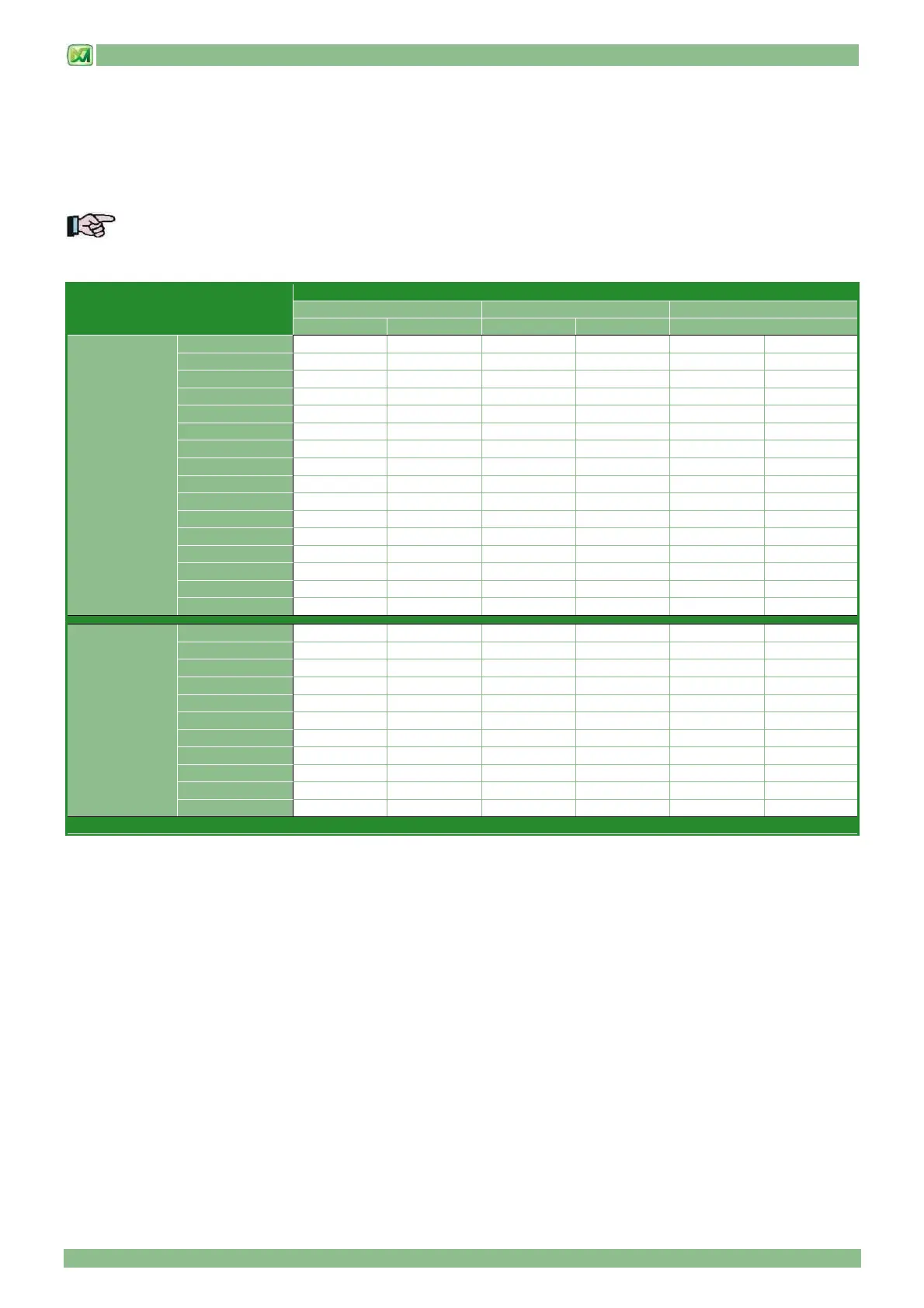

PICHT

FINE

M8 x 1

27 2.75 40 4.08 47 4.79

M10 x 1.25

53 5.4 78 7.95 91 9.28

M12 x 1.25

95 9.68 139 14.17 163 16.62

M14 x 1.5

150 15.29 220 22.43 257 26.2

M16 x 1.5

229 23.34 336 34.25 393 40.06

M18 x 1.5

345 35.17 491 50.05 575 58.61

M20 x 1.5

482 49.13 687 70.03 804 81.96

M22 x 1.5

654 66.67 932 95.01 1090 111.11

M24 x 2

814 82.98 1160 118.25 1360 138.63

M27 x 2

1200 122.32 1700 173.29 1990 202.85

M30 x 2

1670 170.23 2370 241.59 2780 283.38

Nm = Newton-meter / lbft = pound - foot kgm = kilogram - meter

END OF SECTION

Loading...

Loading...