High vacuum or suction may create fluid siphoning. In this

situation, you must check the integrity of the set used (possible

leakage). In order to address those issues our sets are fitted

with an anti-siphon valves or need to be used with an anti

siphon valve inserted in the line.

Pressure variation may generate flow discontinuity mainly

noticeable at low flow rates and depending upon the infusion

system characteristics such as infusion set compliance,

stickiness, compliance of syringes and mechanical back lash.

Anti-siphon valves will also eliminate any risk of free flow during

set changes. The vertical distance between the top level of fluid

administered inside the container and the injection site should

be one meter height maximum. An air leakage in a set with a

line not equipped with an anti-siphon valve may generate an

uncontrolled flow delivery.

Do not use in conjunction with positive pressure infusion

devices that could generate back pressure higher than 2000

HPa susceptible to damage infusion administration set and the

pump.

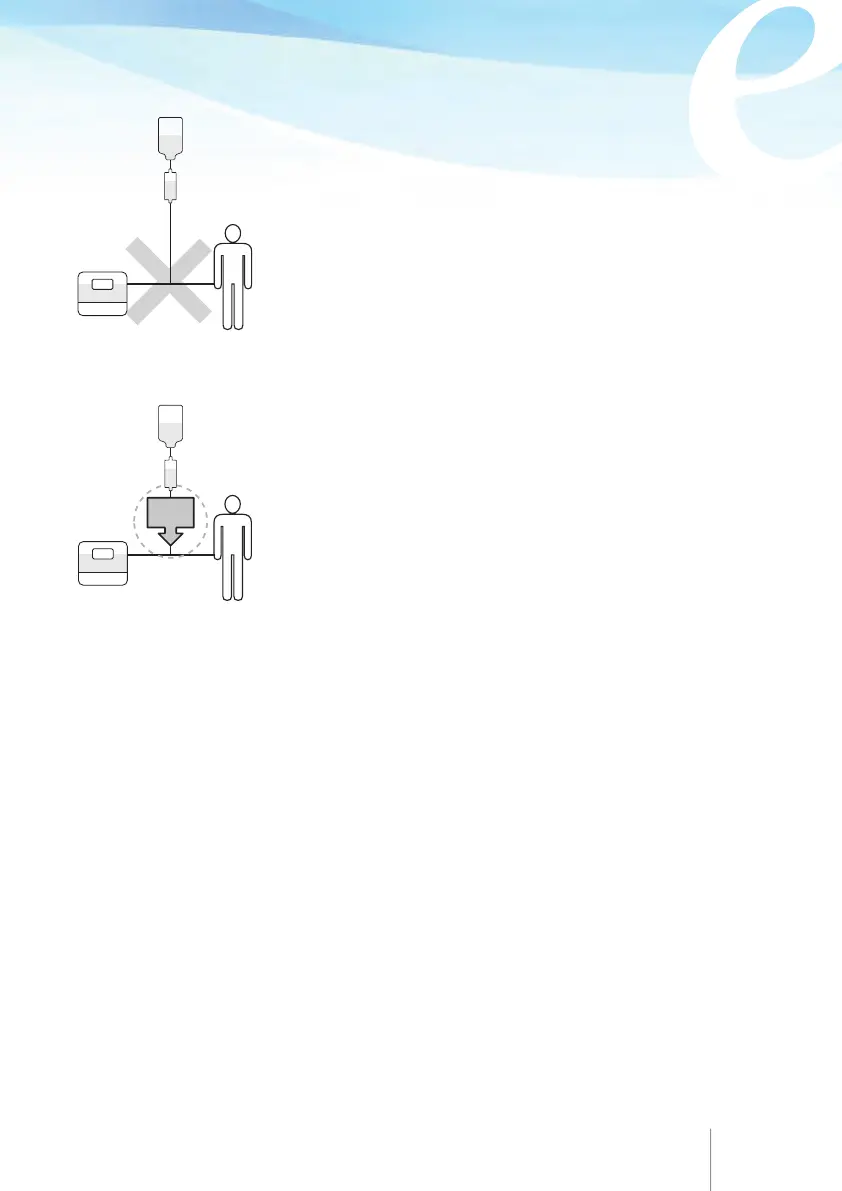

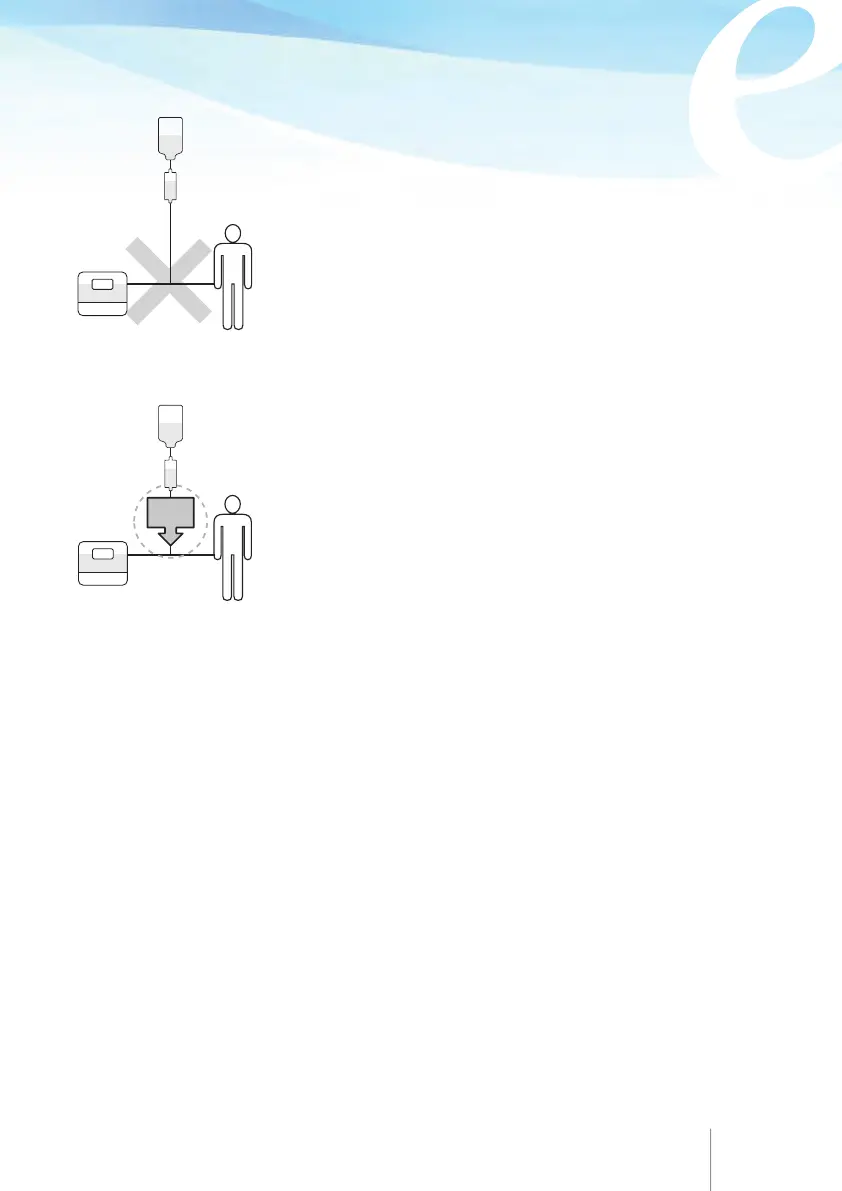

Micrel recommends the use of one-way valves or positive

pressure infusion devices for multi-line infusions. If there is

no one way valve on a gravity infusion line during a multi-line

infusion, this will make it impossible to detect occlusions on the

patient side, and could result in accumulation of the drug being

infused in the gravity line, which could later be infused in an

uncontrolled manner when the occlusion is released. Place the

connection between the feeder line and the pump line as near

to the patient side as possible in order to minimise the dead

space and consequently the impact of any change in flow rate

on the feeder line.

104 105

Loading...

Loading...