Troubleshooting Anesthetic Gases and O

2

Concentration Monitoring

7 - 10 Operator’s Manual of Anesthesia System

NOTE: Inaccuracy is specified at 10-55 °C operating temperature and default

compensated for an H

2

O partial pressure of 11 mBar (i e 22 °C @40% RH

ambient conditions) and using a DRYLINE

TM

sampling system. Any

other ambient H

2

O partial pressure will dilute the gas sample to a

different extent, causing a measurement error. Under typical operating

conditions this effect is negligible. An increase of the ambient H

2

O

partial pressure to 30 mBar (i e 28 °C @80% RH or 33 °C @60% RH) will

cause a general error for all measured gases of -2%

REL

. For automatic

compensation of the ambient humidity effect on the gas sample

composition, the actual ambient H

2

O partial pressure can be input to

AION

TM

from the host via the communication interface.

7.9 Troubleshooting

If the gas inlet (including watertrap, sampling tube and airway adapter) is occluded by condensed

water, airway occlusion will be prompted on the screen.

To remove the occlusion:

• Check the airway adapter for occlusion and replace it if necessary.

• Check the sampling tube for occlusion or kinking and replace it if necessary.

• Check the watertrap for water accumulation. Empty the watertrap. If the problem persists,

replace the watertrap.

If the problem persists, internal occlusions may exist. Contact your service personnel.

If the exhaled O

2

concentration is higher than the inhaled O

2

concentration, it may be because of an

overly low pump rate. It is recommended to set [Pump Rate] to [High].

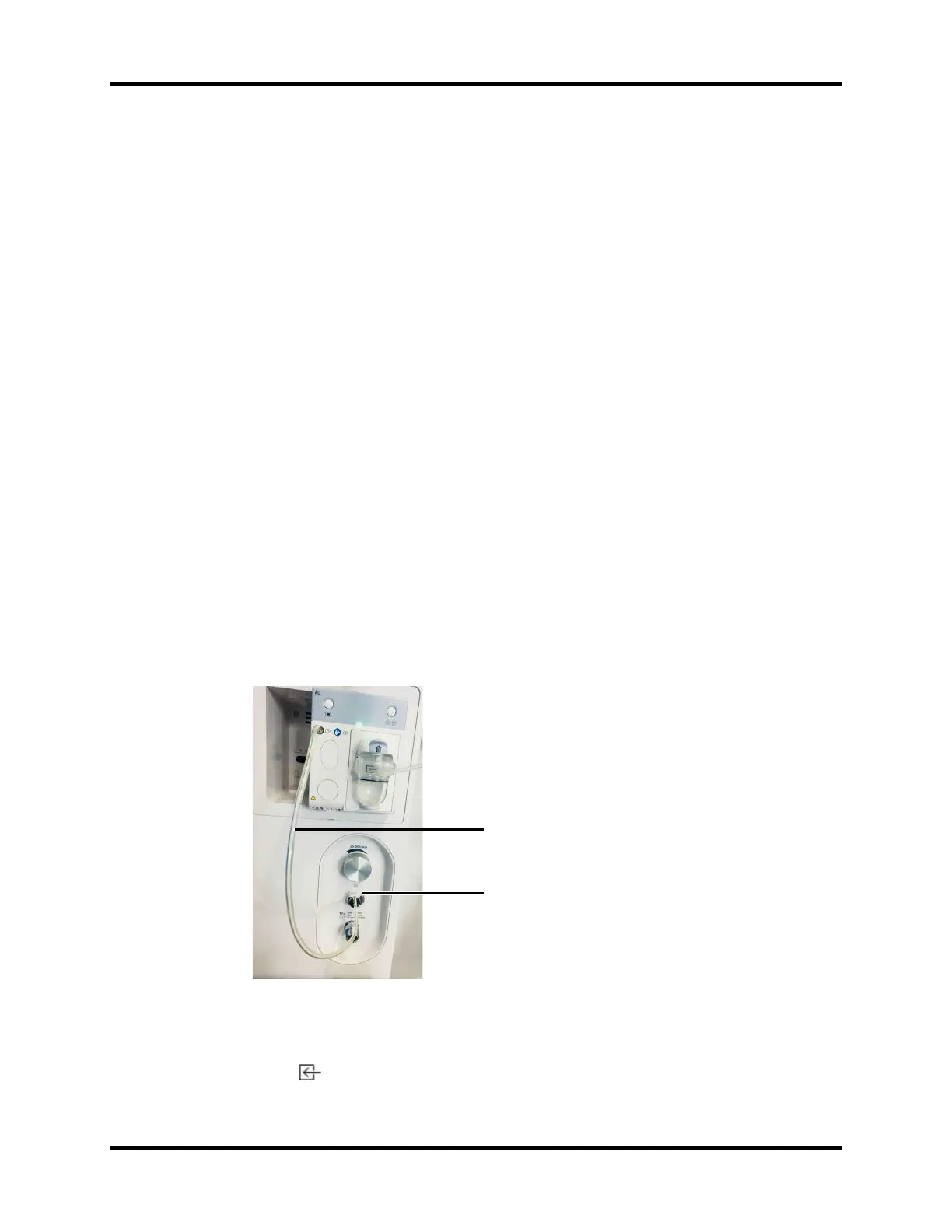

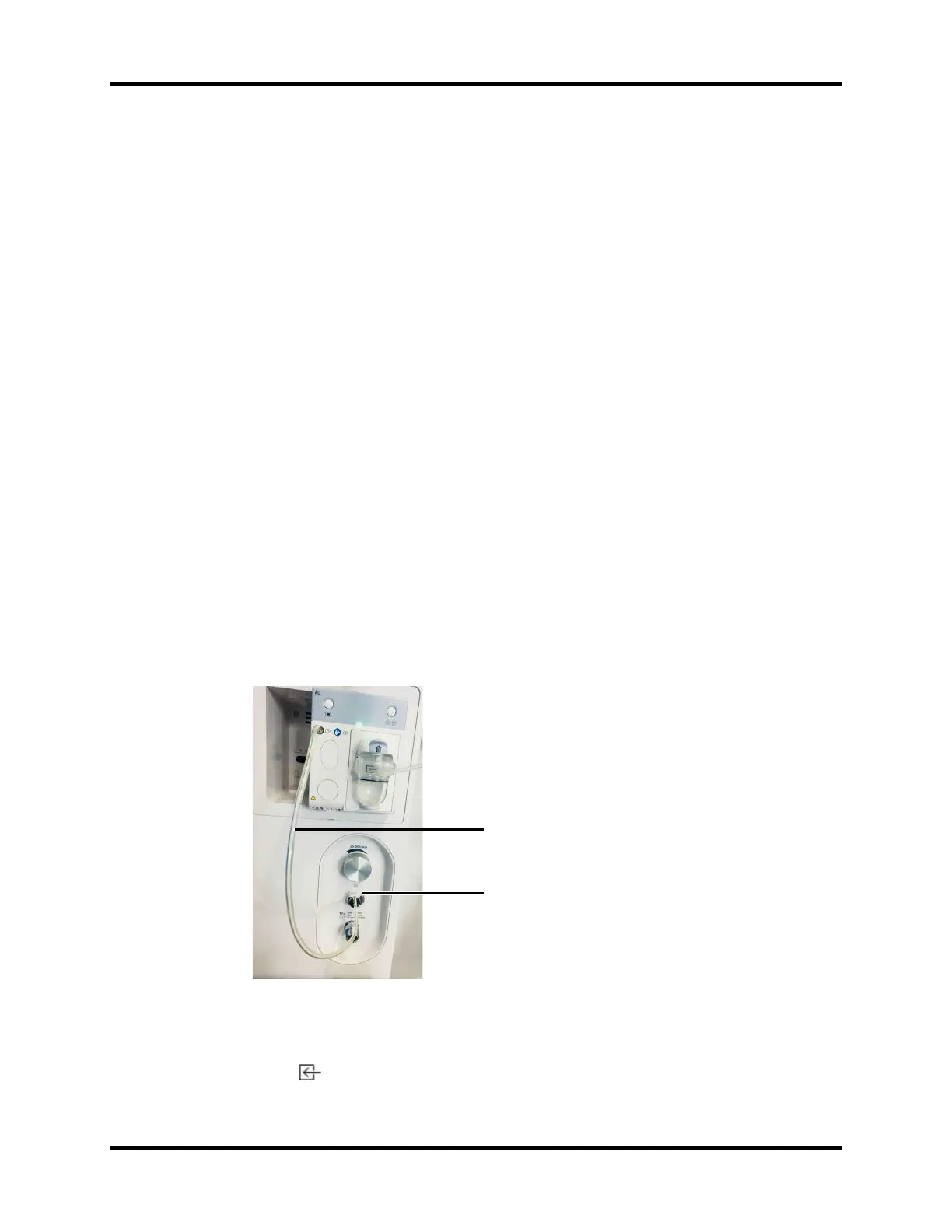

7.10 Sample Gas Recirculation

Figure 7-6 Sample gas recirculation

To return the sample gas to the patient circuit, plug the exhaust tube into the sample gas return port

marked . A click indicates that the connector of the exhaust tube is installed in place, as shown

above. Depress the metal clip to pull out the exhaust tube.

Loading...

Loading...