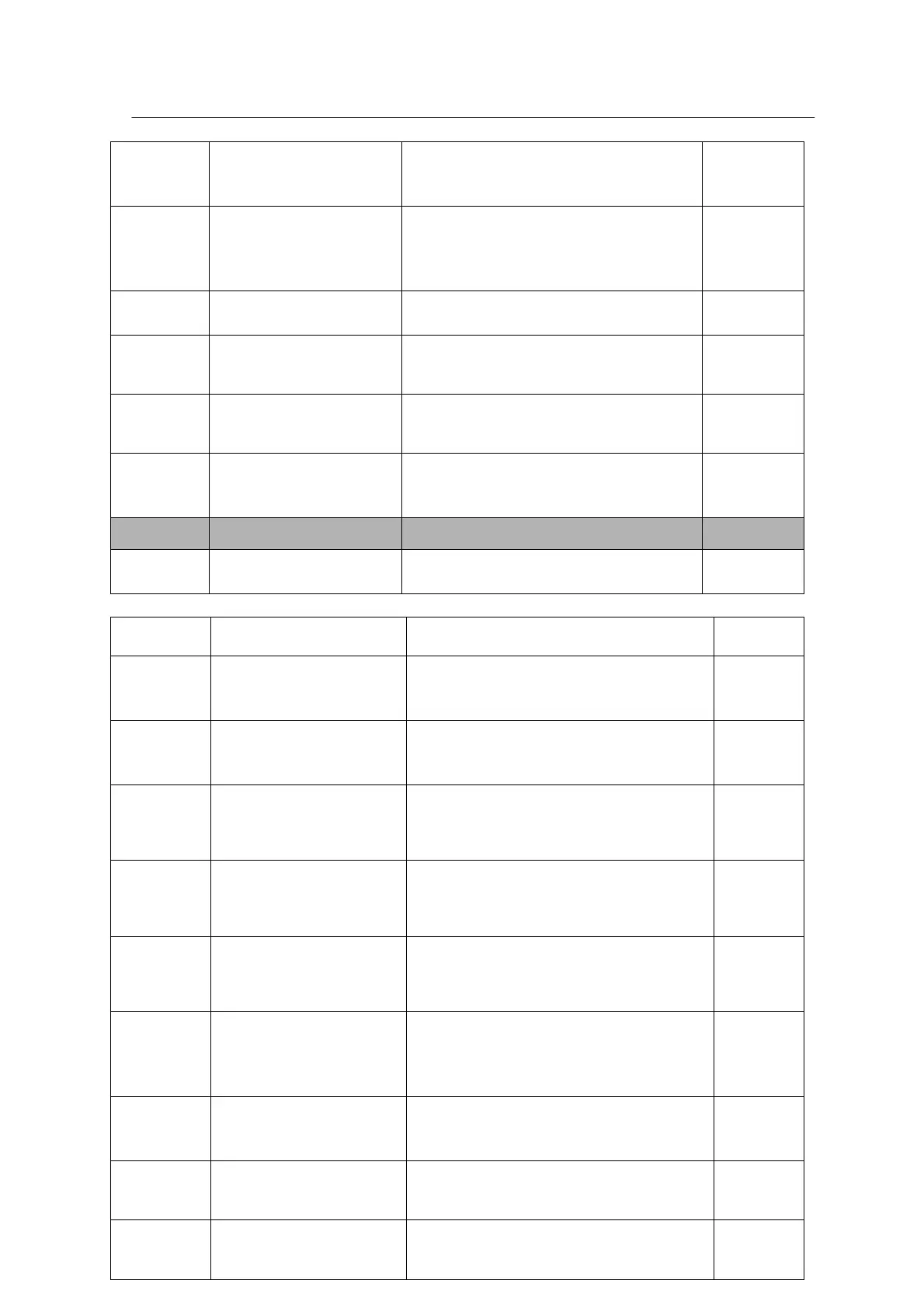

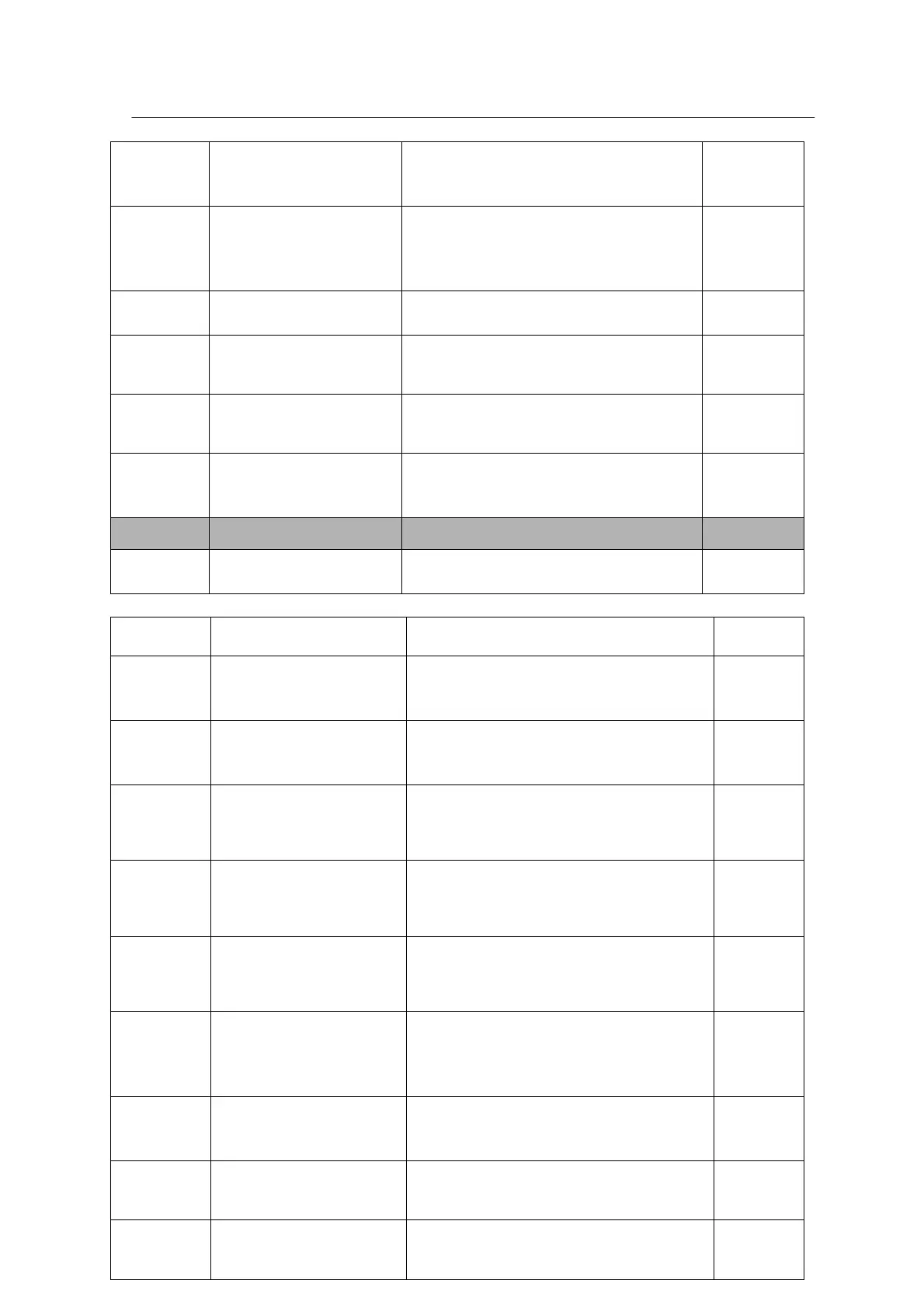

Chapter 5 Solutions for Errors 5-

9

Remove the chip from

the bad chip

discharging conveyer.

Error of the sensor that

detects the discharging

position on the bad chip

discharging conveyer.

Position detection

sensor error

Check the solenoid valve and Air line.

Check the sensor.

Check the solenoid valve and Air line.

Check the sensor.

PCB is present on the

Work 1 conveyer when

homing.

Take out the board and do homing.

PCB is present on the

Work 1

Take out the board and do homing.

PCB is present on the

loading conveyer when

homing.

Take out the board and do homing.

PCB is present on the

exit conveyer when

homing.

Take out the board and do homing.

PCBs are present on the

entrance and Work 1

conveyers when homing.

Take out the board or adjust the sensor

position.

PCBs are present on the

Work 1 and Work 2

conveyers when homing.

Take out the board or adjust the sensor

position.

PCBs are present on the

Work 2 and exit

conveyers when homing.

Take out the board or adjust the sensor

position.

Large offset between

the PCB width of the

conveyer and PCB

width in the Job file.

Check the conveyer width and the PCB

size. Check the job file.

The conveyer cannot

move because the Z-

axis is lowered.

Check the Z -axis position and then run

the conveyer.

ORG error during

conveyor operation

Carry out PCB Manual Control after Z -

axis homing.

Conveyor PCB

discharging error.

Check conveyer belt and sensor.

Loading...

Loading...