Failed to reset parameter

Enter data on intelligent

feeder. Use the default

parameter.

Communication related

warning message

Communication error increases.

If it continues, check the feeder cable.

Needs inspection as

feeding count exceeds a

designated value (cf. 5

million feedings)

Needs inspection due to excessive

usage. You can still use the feeder.

Feeding is performed as

the operator presses the

right switch

Check points before production

Make sure to check the following points before starting

production.

Check if the part supply

point of the feeder is in

the center of the picking

position.

1) Check the picking position

after auto feeding. Make sure not to

each the position moved by the

impact of mounting.

2) Use auto teaching (refer to

the manual).

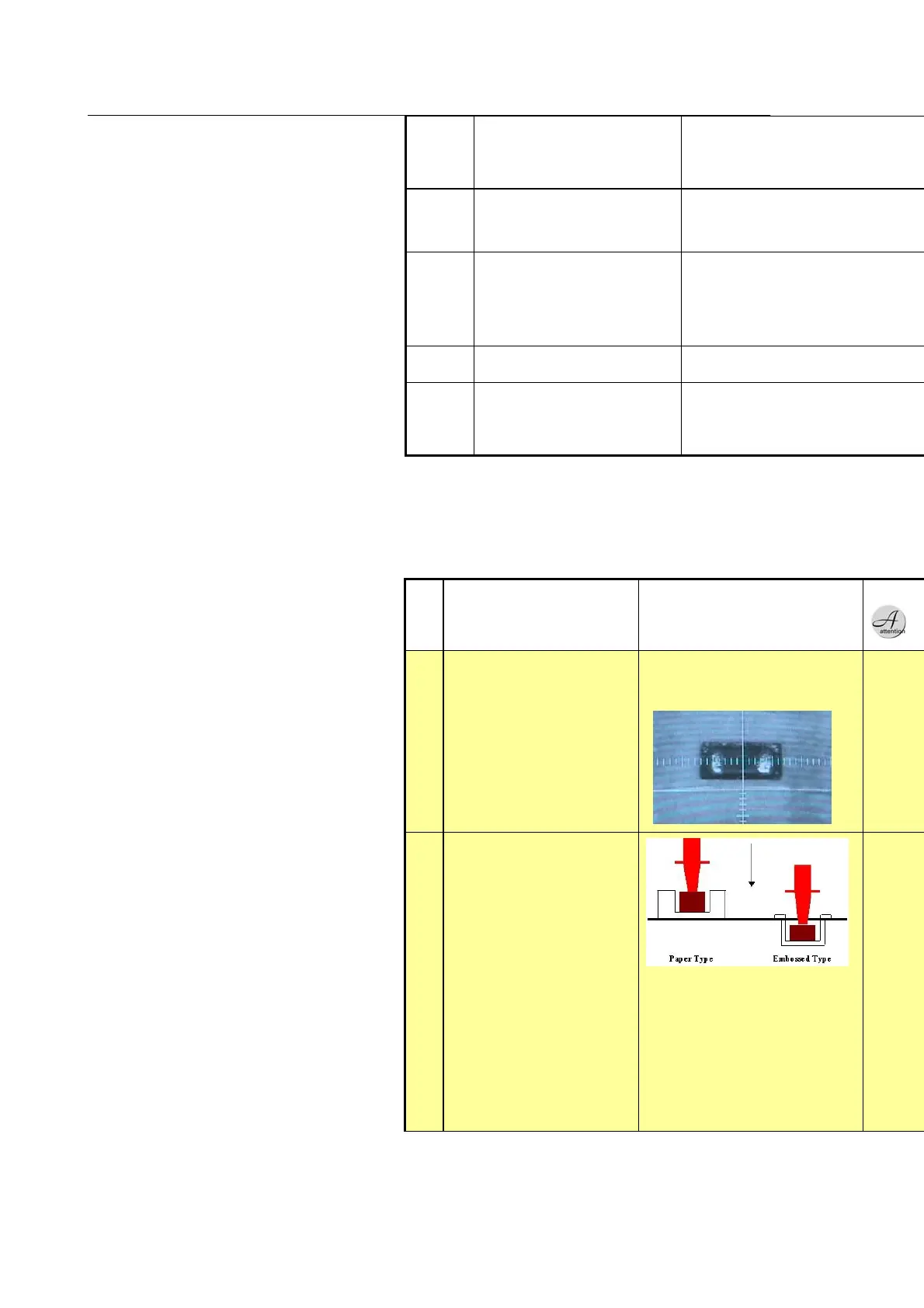

Is the pickup height

appropriate?

Measure the distance

between the nozzle end

and picking surface (chip

surface), and enter the

height value. The default

is

25.0.

Hint> Measure height for 1608 paper

and emboss, and enter the typical

value, rounding off to the second

decimal place. If the measured value

is

24.82, enter 24.9.

In case of 1005 and 0603, make the

table to reduce loss.

Refer to the equipment manual or

contact CS for height measuring

method.

Loading...

Loading...