4-8 Mx-Series Operation Manual

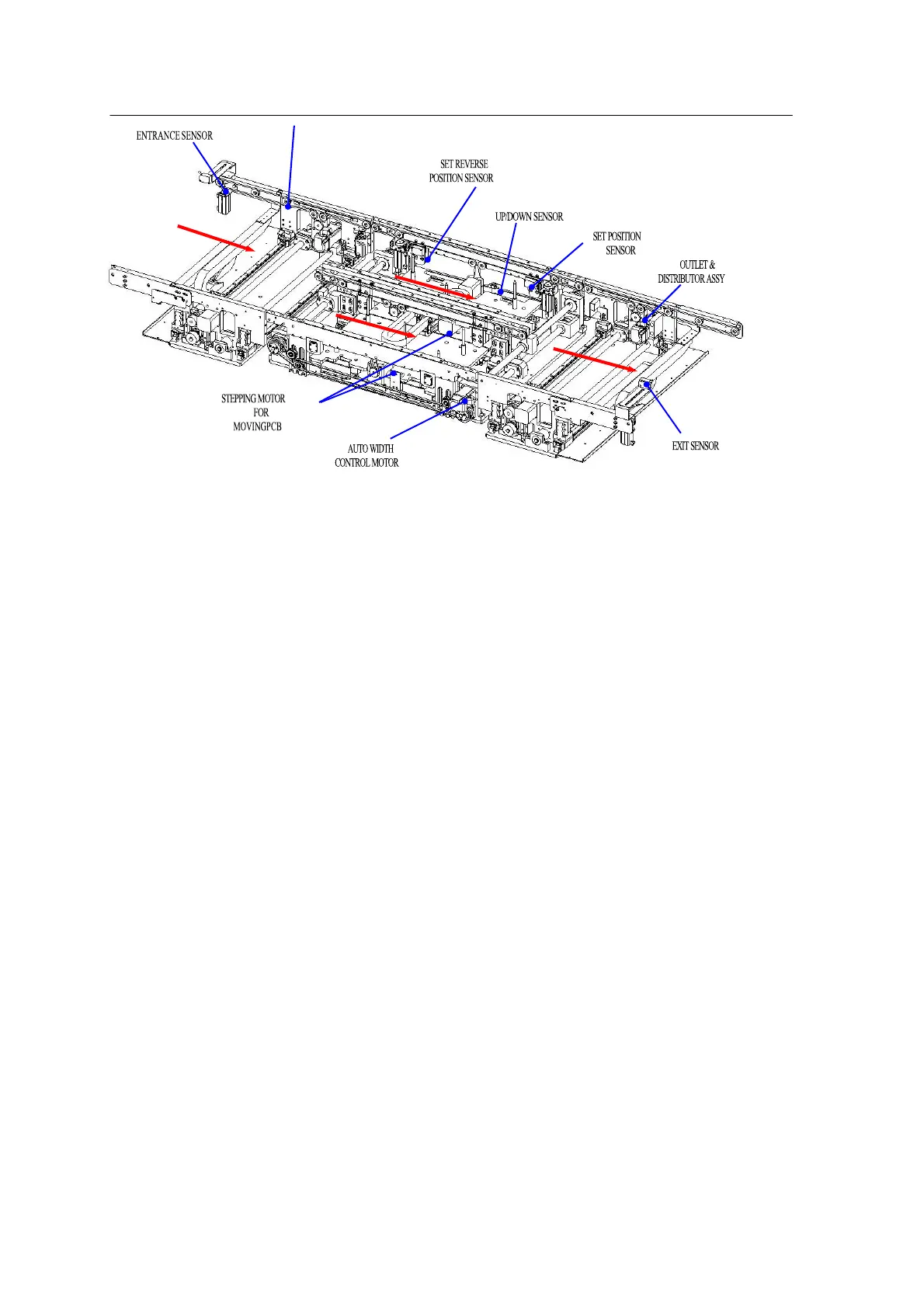

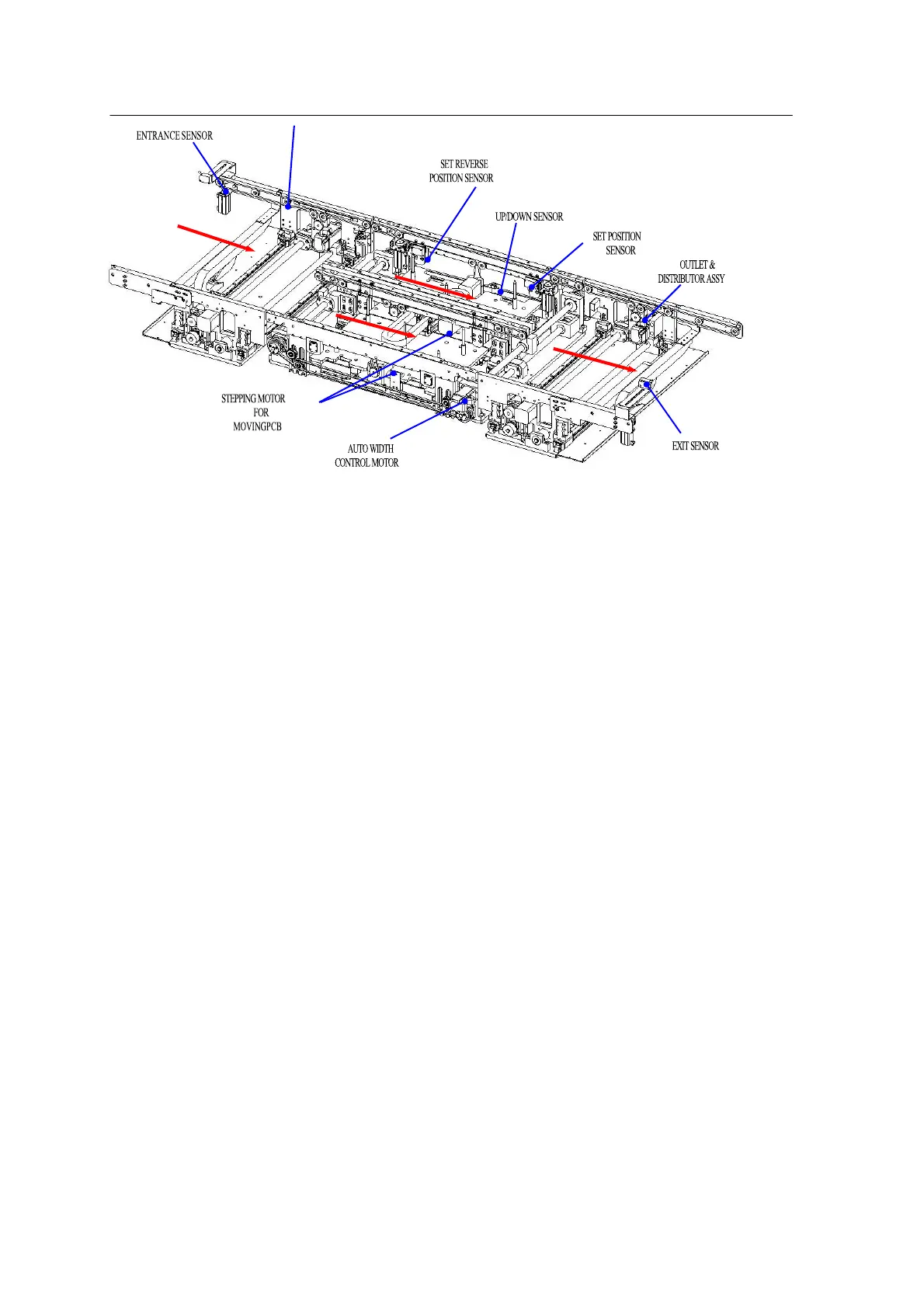

<Figure 4-4 3-stage structure of dual conveyer>

• Functions

The inlet conveyer receives a PCB (Printed Circuit Board) and transfers it to

the placement position on the work conveyor.

When the PCB enters the WORK area, the main stopper stops the PCB and

fixes it with the fixation plate and Push Up Device so the head can place the

component.

When component placement is completed, the PCB is transferred to the

next process through the outlet conveyer.

• Features

- Manual/automatic PCB/conveyer width adjustment is supported.

Manual: Manual conveyer width adjustment using a handle

Automatic: Automatic width control depending on the input value.

- PCB mobility protection during placement: When placing a component,

PCB is fixed by the fixation plate and the Push Up Device to prevent the

PCB from bending down or up and to maintain accuracy of placement. In

addition, the work environment is provided irrespective of PCB thickness (*

This is applicable only within the PCB thickness Spec.)

• Soft stop: The soft stop function that controls deceleration of the conveyer

prevents the placed component from being moved or misaligned by impact

when the transferred PWB stops at the work area.

Loading...

Loading...