Glossary

10.06.2014 131

standard

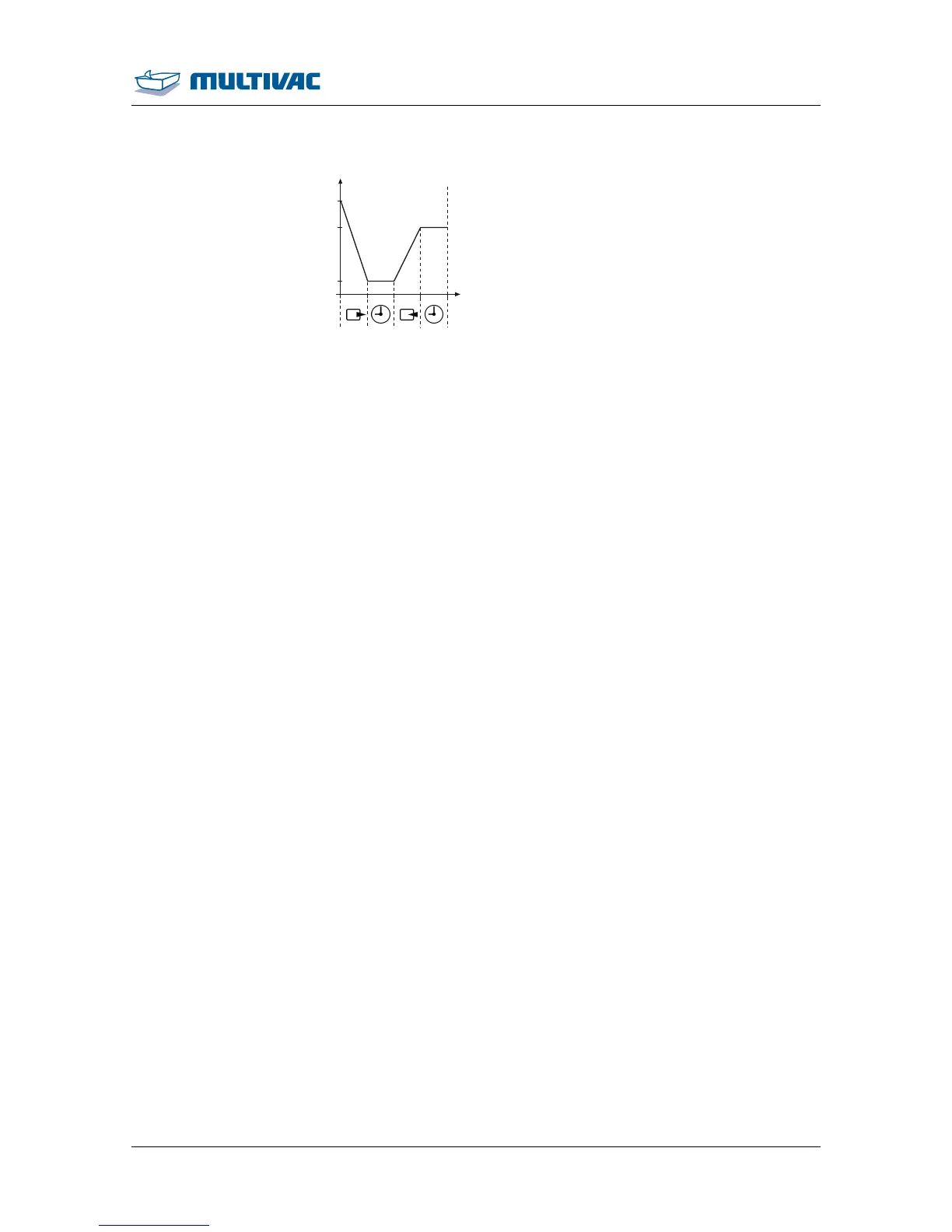

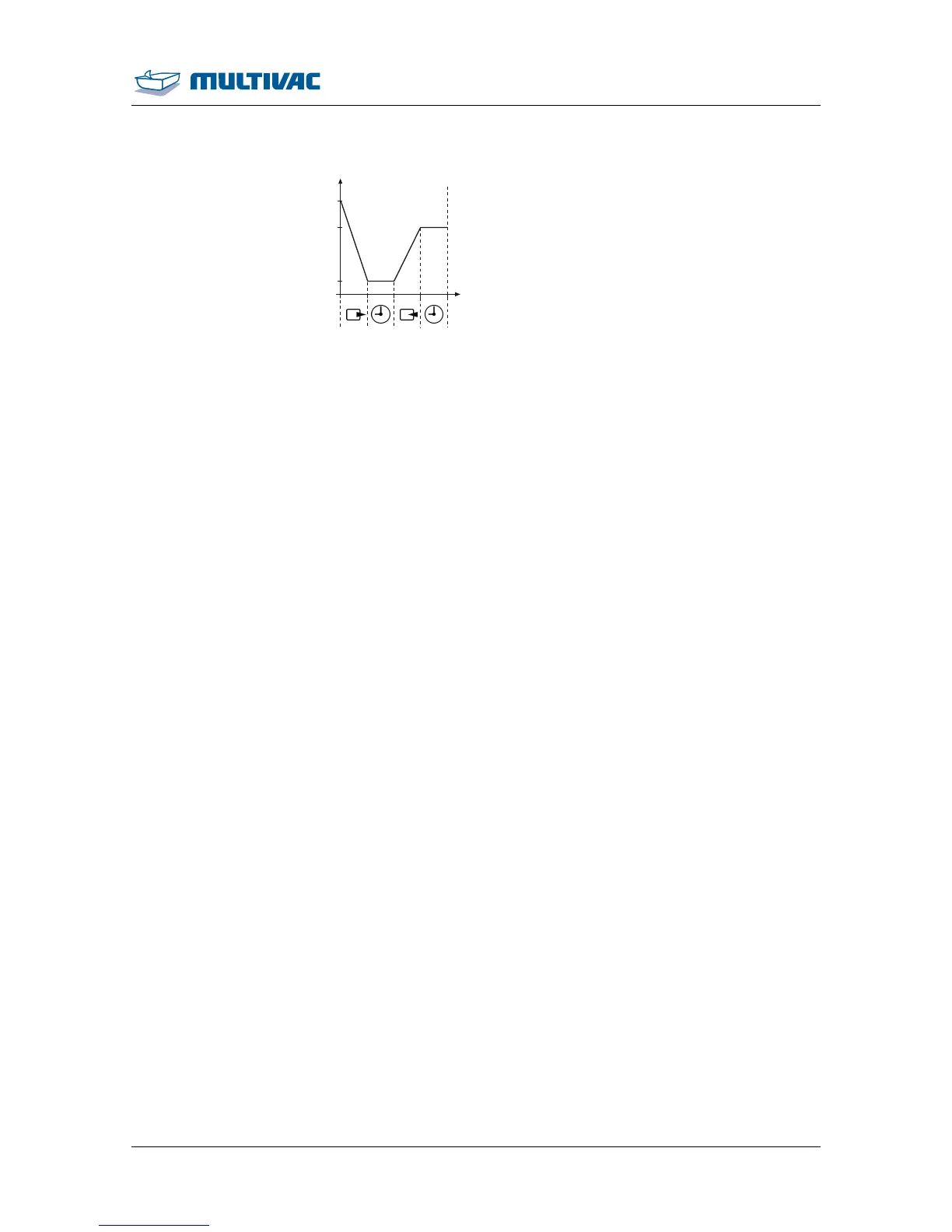

P3

P2

P1

t

P

Fig. 59: Example diagram of standard process

P1

Evacuation pressure

P2

Gas flushing pressure

P3

Ambient pressure

During the standard process, air is suctioned out until the set pres-

sure is reached. Afterwards, gas is flushed at the set pressure (op-

tion).

Technician

A technician is defined as someone who, based on his/her technical

training, knowledge and experience with the product and familiarity

with relevant applicable norms, can evaluate the tasks delegated to

him/her and recognise and avert dangers.

total cycles

[Parameter of the control unit]

Shows the completed machine cycles.

Vacuum pump - Pro-

duction data

[Parameter of the control unit]

Counts the vacuum pump's hours of operation. Counting starts as

soon as the vacuum pump is turned on. The display cannot be

changed.

Vacuum pump run-

ning-on time

[Parameter of the control unit]

After sealing the film pouch, the vacuum pump switches off in a

time-delayed manner by the amount of the running-on time. The

running-on time bridges the temporary stopping of the vacuum

pump. This prevents the vacuum pump from overheating due to con-

tinual switching on and off.

Vacuum test

[Parameter of the control unit]

Automatic leakage test of the vacuum system and the sealing dia-

phragm.

Ventilate diaphragm

[Parameter of the control unit]

During this time the sealing diaphragm is evacuated. The sealing is

without sealing pressure.

Ventilation

During ventilation the pressure in the chamber adapts to the ambient

pressure. As a result of this, the film pouch shrinks tightly to the

product. After the chamber has been ventilated the lid opens auto-

matically, if it is not locked. .

Loading...

Loading...