6-2Service ManualXYAA6336

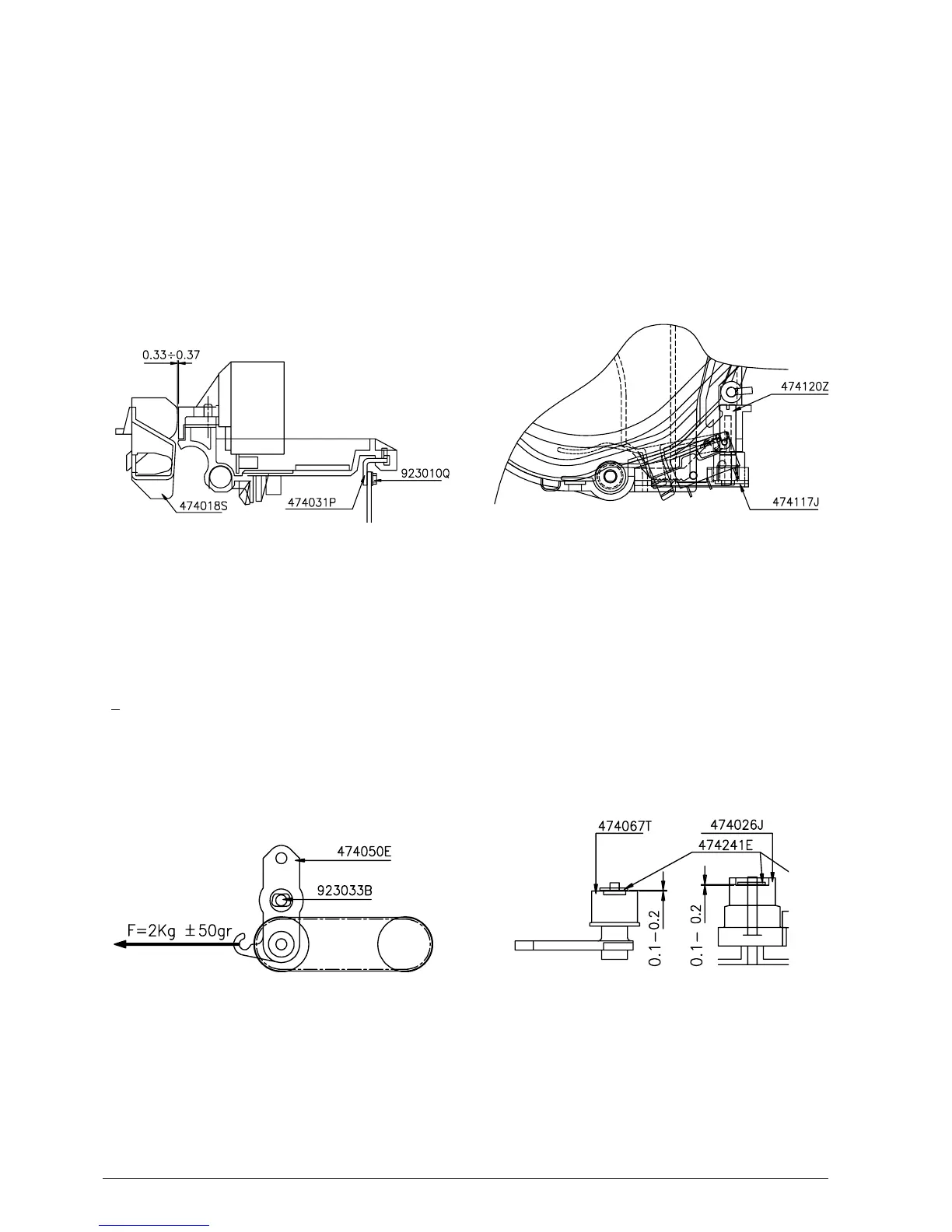

6.2 ADJUSTING THE PARALLELISM

AND PRINT HEAD-PLATEN

DISTANCE

By means of friction screws 923010Q, higher or lower

the plate code 474031P until obtaining the parallelism

between the print head and platen. Then check, using

a probe, for a clearance of 0.33 - 0.37 mm between

the needle profile and platen code 474018S (Fig 6-2).

6.4 ADJUSTING THE OUT OF

JOURNAL AND RECEIPT PAPER

MICROSWITCH SUPPORT

PR4: Position the microswitch support half way along

the total run using the tab regulator code 474120Z

(Fig. 6-4) or according to the client's requirements.

PR4 SR: Position the microswitch support as follows:

for a 139.7 mm wide roll, all the way forwards towards

the operator; for 114.3 and 82.6 wide rolls, half way

along the total run; for the 72.6 mm wide roll, all the

way backwards from the operator.

Figure 6-2

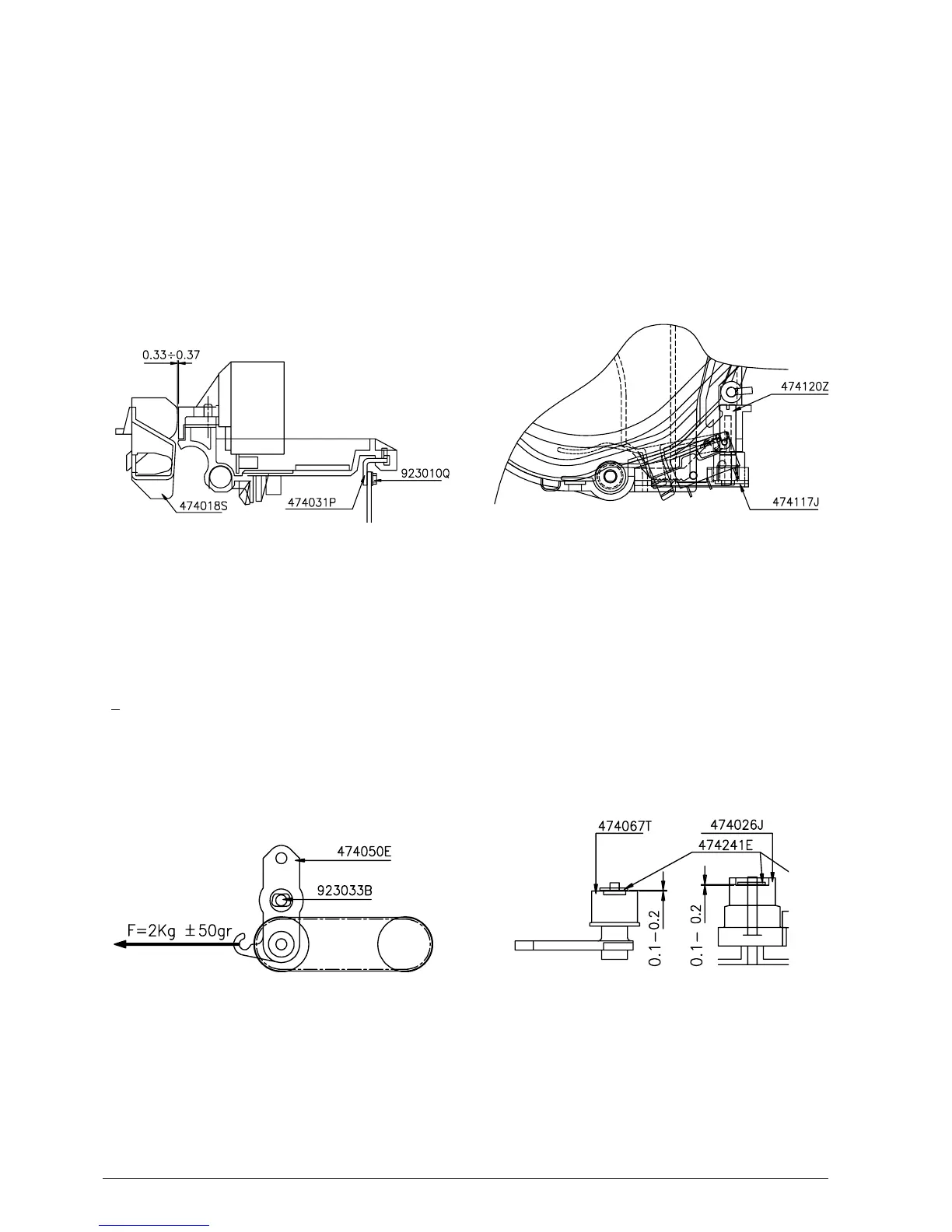

6.3 ADJUSTING THE TENSION OF THE

CARRIAGE TRANSPORT BELT

Pulling the end pulley support bracket with a

dynamometer in the direction of the arrow, tighten the

transport belt until reaching a value of 2 Kg

+ 50 gr. Using the screw code 923033B, block the

bracket code 474050E on the structure code 474015P

(Fig. 6-3).

Figure 6-3

Figure 6-4

Figure 6-5

6.5 MOUNTING THE SNAP RINGS ON

THE CARRIAGE TRANSPORT

ASSEMBLY

During the assembly of codes 474067T, 474059B and

474026J, snap ring code 474241E must have a

clearance of 0.1 - 0.2 (Fig. 6-5). Clearance is obtained

by inserting a probe between the snap ring and the

stop point.

Loading...

Loading...