190

Interrupt Functions Section 5-1

Setting the Input Functions in the PLC Setup

Normally, bits CIO 0.00 to CIO 0.01 and CIO 1.00 to CIO 1.03 are used as

normal inputs. When using these inputs for input interrupts, use the CX-Pro-

grammer to change the input’s setting in the PLC Setup.

Procedure

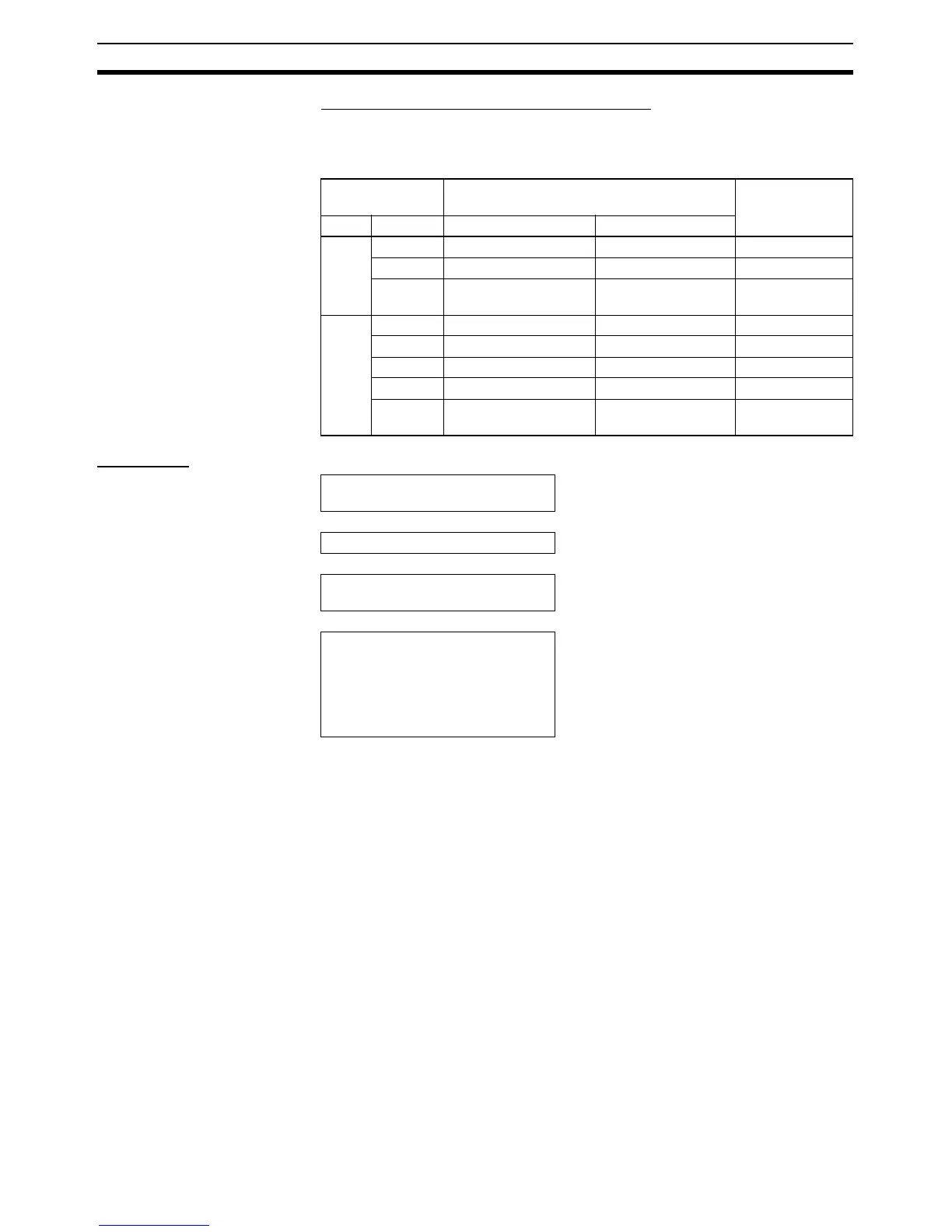

Input terminal

block

Input operation setting Task number

Word Bit Normal inputs Input interrupt

CIO 0 00 Normal input 0 Input interrupt 0 Interrupt task 140

01 Normal input 1 Input interrupt 1 Interrupt task 141

04, 05, 10

and 11

Normal inputs 2, 3, 4,

and 5

--- ---

CIO 1 00 Normal input 6 Input interrupt 2 Interrupt task 142

01 Normal input 7 Input interrupt 3 Interrupt task 143

02 Normal input 8 Input interrupt 4 Interrupt task 144

03 Normal input 9 Input interrupt 5 Interrupt task 145

04 and 05 Normal inputs 10 and

11

--- ---

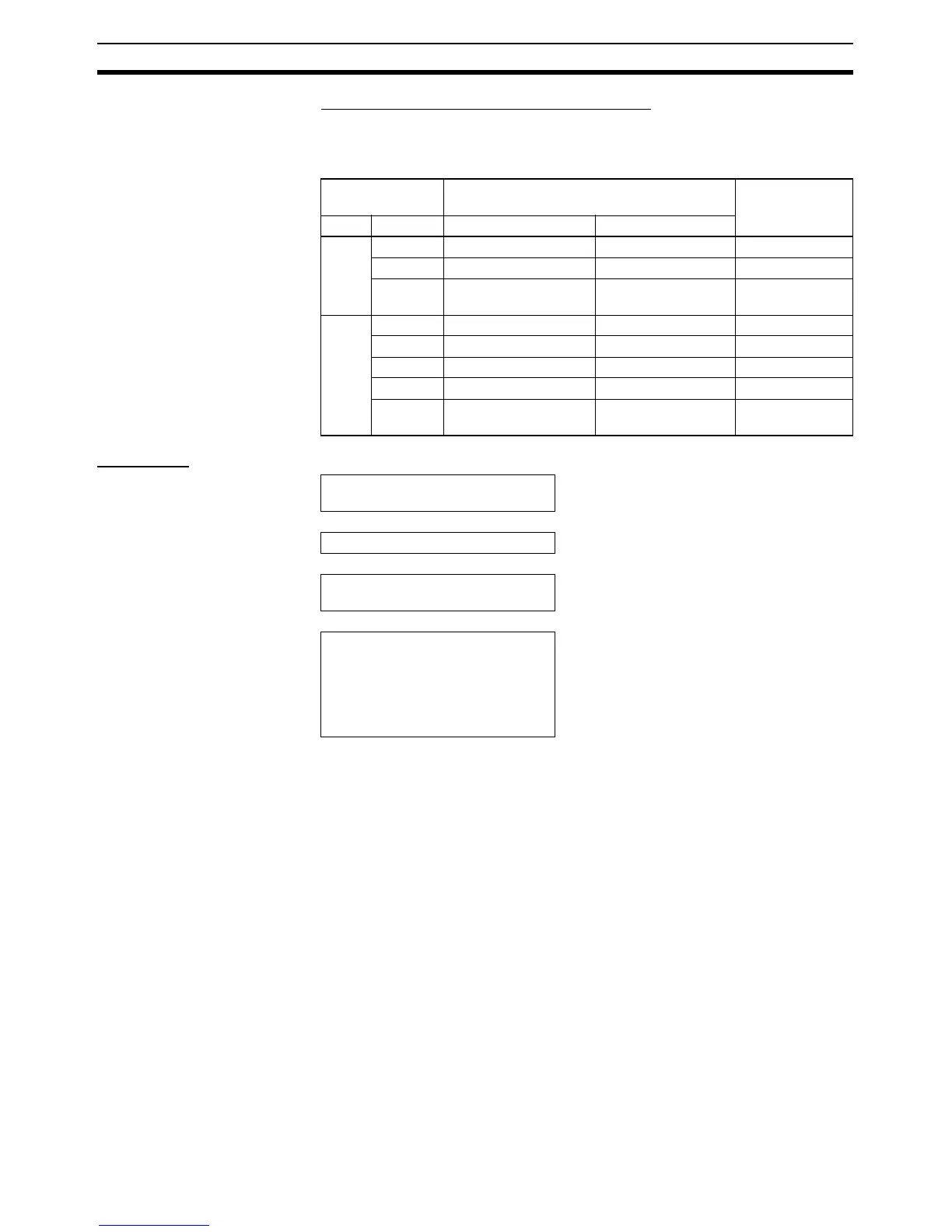

Select the input interrupts.

• Determine the inputs to be used for input

interrupts and corresponding task numbers.

↓

Wire the inputs. • Wire the inputs.

↓

Set the PLC Setup.

• Use the CX-Programmer to select the inter-

rupt inputs in the PLC Setup.

↓

Write the ladder program.

• Write the programs for the corresponding

interrupt task numbers.

• Use MSKS(690) to specify up-differentiation

or down-differentiation.

• Use MSKS(690) to enable input interrupts (in

direct mode).

Loading...

Loading...