5-17

5 Motion Control Parameters

NJ/NX-series CPU Unit Motion Control User’s Manual (W507)

5-2 Axis Parameters

5

5-2-3 Unit Conversion Settings

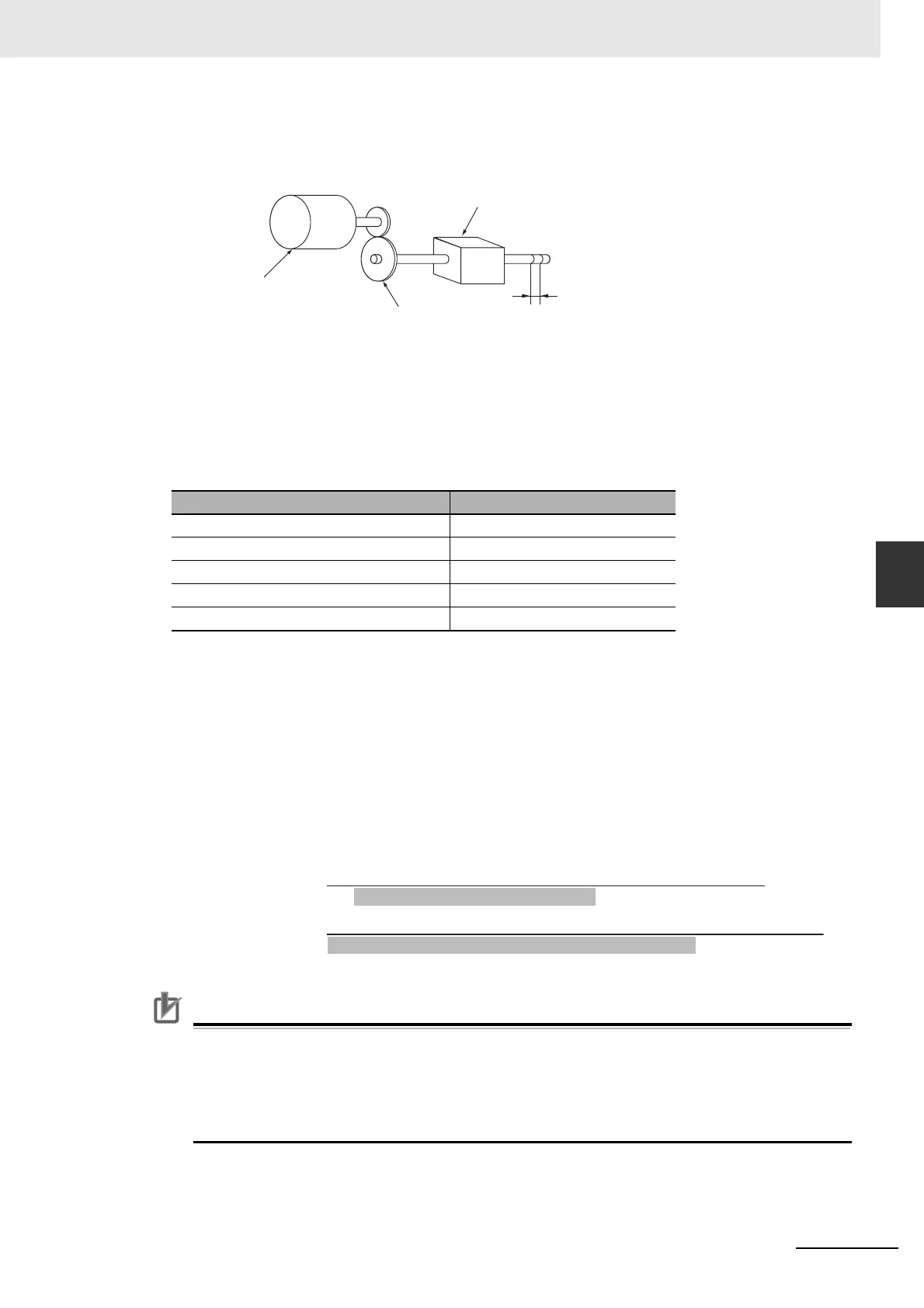

In this example, an OMRON 1S-series Servomotor with a 23-bit absolute encoder is used.

Mechanically, the reduction ratio of the reducer is 3/5 and the workpiece moves 10 mm for every

rotation of the ball screw.

The Unit of Display parameter is set to millimeters. The Command Pulse Count Per Motor Rotation

is set to the resolution of the encoder on the Servomotor.

The Work Travel Distance Per Rotation is set to 10 mm, which equals to the ball screw pitch.

A reducer with a reduction ratio of 3/5 is used, so the ball screw turns three times for every five rota-

tions of the Servomotor. For this reduction ratio setting, the work gear ratio is set to 3 and the motor

gear ratio is set to 5.

With these settings, the command unit for positions in the user program is 1 mm.

For example, to move to an absolute position of 100.5 mm, the Position (Target Position) input vari-

able to the MC_MoveAbsolute (Absolute Positioning) instruction is set to 100.5.

When Using a Reducer and the Count Mode Is Rotary Mode

When you set to use a reducer and the Count Mode is Rotary Mode, the following calculation for-

mula is used to have the electric gear ratio.

In Rotary Mode, the Work Travel Distance Per Rotation is automatically determined and set by the

result of “Modulo maximum position - Modulo minimum position”.

Precautions for Correct UsePrecautions for Correct Use

The electronic gear converts units to the values that are used for positioning by the MC Func-

tion Module and motion control instructions.

Motion control instructions specify the target position as LREAL data. However, an instruction

error will occur if the command position after conversion to pulses by the electronic gear

exceeds 40 bits.

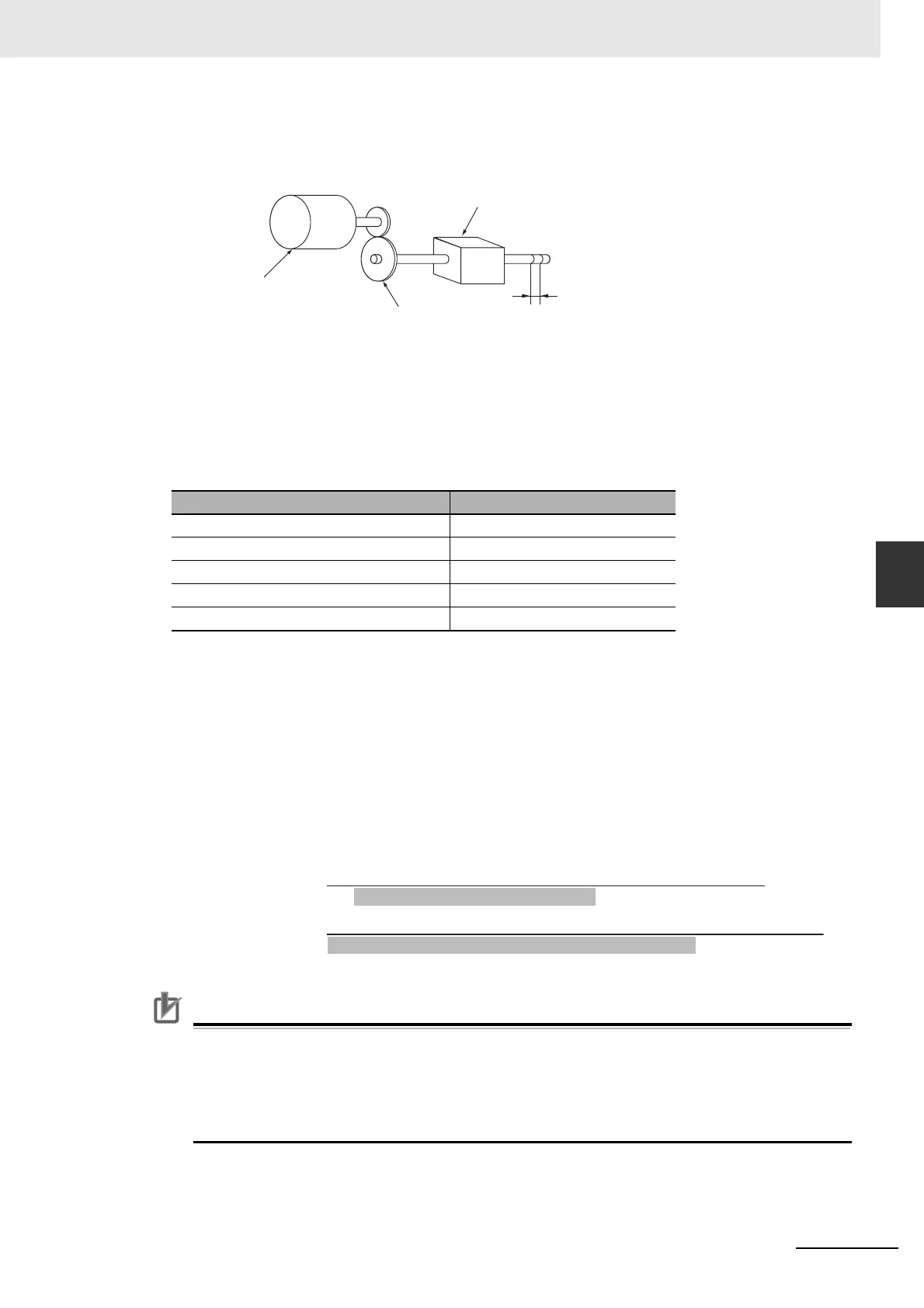

Parameter name Setting

Unit of Display mm

Command Pulse Count Per Motor Rotation 8,388,608

Work Travel Distance Per Rotation 10

Work Gear Ratio 3

Motor Gear Ratio 5

Reduction ratio: 3/5 Ball screw pitch: 10 mm

Servomotor encoder

resolution: 23 bits/rotation

(8,388,608 pulses per rotation)

Workpiece

Electronic gear ratio =

Command Pulse Count Per Motor Rotation

× Motor Gear Ratio

Command Pulse Count Per Motor Rotation

× Motor Gear Ratio

Work Travel Distance Per Rotation

× Work Gear Ratio

=

(Modulo maximum position - Modulo minimum position)

× Work Gear Ratio

Loading...

Loading...