Sealing

28

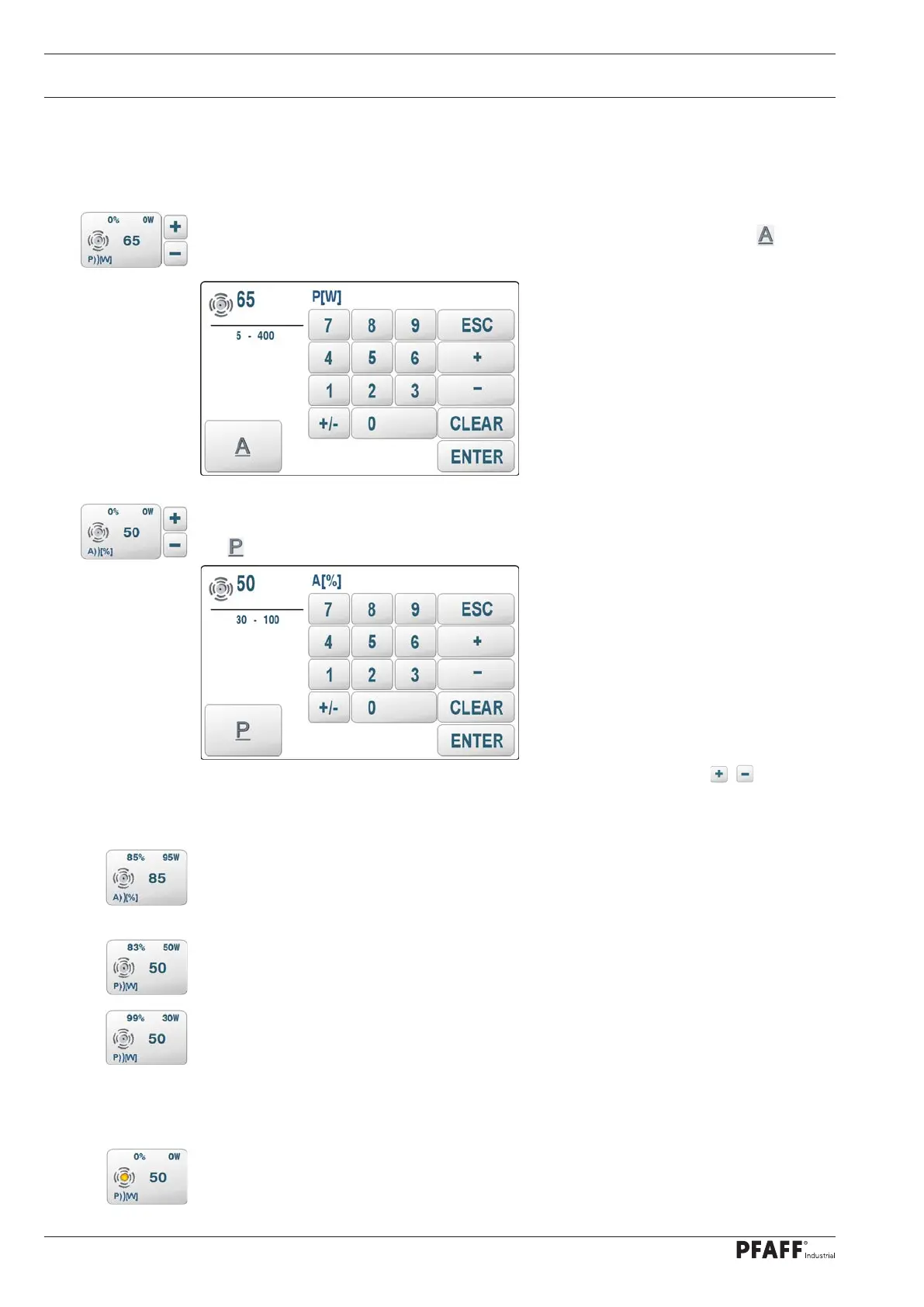

10.02.02 Ultrasonic power/amplitude

The ultrasonic generator of the 8311 can be operated with amplitude control or with power

control. The switch over takes place when inputting the setpoint value.

An ultrasonic power of between 5 W and 400 W can be entered by pressing the ultrasonic

power touch field. A new input screen will open for this purpose. The special key can be

used to switch to amplitude welding.

An ultrasonic amplitude of between 30% and 100% can be entered by pressing the

ultrasonic amplitude touch field. A new input screen will open for this purpose. The special

key can be used to switch to power welding.

The displayed parameter can also be changed directly by scrolling with the / keys.

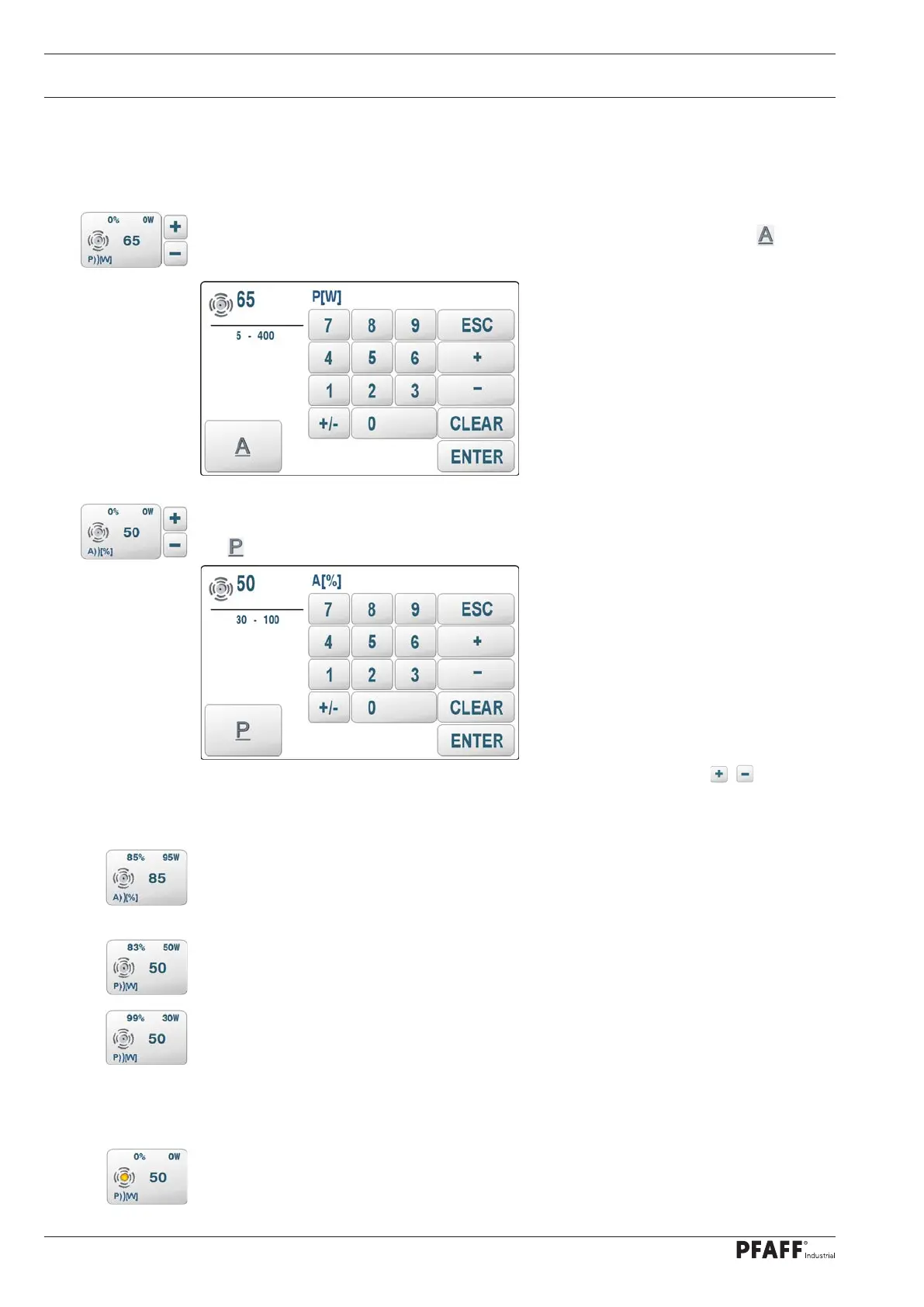

In welding mode, the current values (actual values) of the ultrasonic amplitude and the

ultrasonic power are displayed at the top of the touch field.

Sample display – amplitude welding: The current amplitude value is approximately the same

as the setpoint value. It is not affected by the other welding parameters. The resulting power

(and therefore the welding result) in contrast is also determined by the other parameters

(force, speed, roller gap).

Sample display – power welding: If the other parameters (force, speed, roller gap) match,

the generator can maintain the power at the desired setpoint value by varying its regulating

amplitude variable.

Sample display – faulty power welding: In this example, the generator cannot maintain the

power at the desired setpoint by varying its regulating amplitude variable. This status can be

seen by the amplitude value of 98%..100% at reduced power. The other parameter (force,

speed, roller gap) must be adjusted here.

If deviations of the generator actual values are not tolerated, error limits can be defined; if

these are exceeded, the machine interrupts the welding process with an error message.

Displays of 0% 0W indicate that the ultrasonic generator is currently switched off.

A yellow LED on the Sonotrode symbol additionally indicates that the generator has been

switched off by the control software (Sonotrode protection function or welding program

command welding off).

Loading...

Loading...