Sealing

45

10.07 Programmed sealing

Programs can be created with up to 12 sections by linking multiple data sets P1..P50 into

one unit. It is possible to switch to the next linked data set (section) via a welding distance

(length specification), via programmable inputs (switches), via a change in material thickness

or by the operator pressing the pedal.

The welding parameters of the individual sections remain constant during processing.

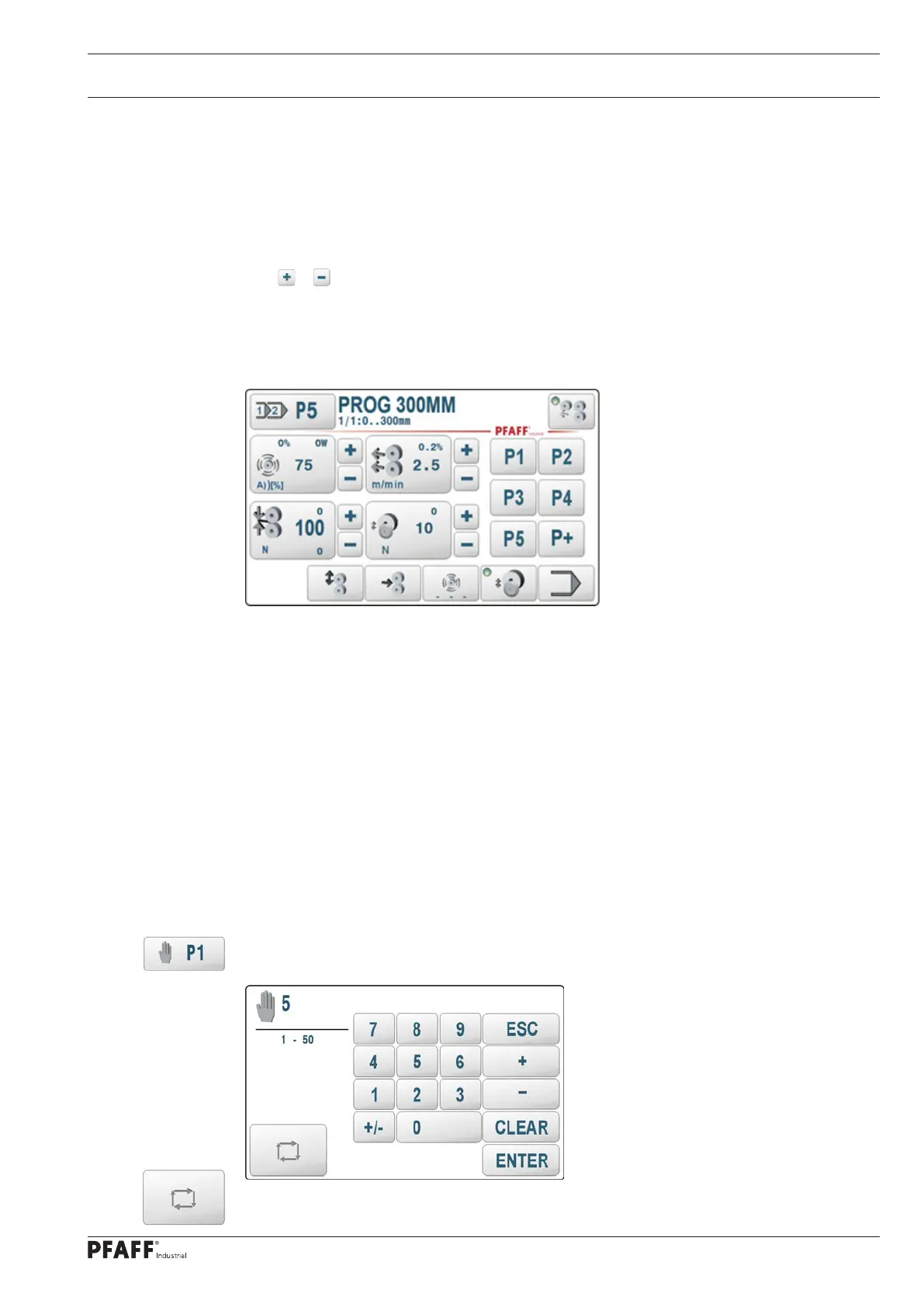

The / keys can also be used to adjust parameters during the welding process.

After executing the program (warp) or after cancelling the process with the pedal -1 function,

the process returns to the first section of the program chain (or switches to another program

chain – see sequences). An editor is available to create a welding program, which creates

the links between the necessary data sets.

10.07.01 Program

By linking several data records P1..P50 to one unit, programs with up to 12 areas can

be created. The program number is the number of the first area. Switching to the next

linked data record (area) can take place via a welding section (length specification), via

programmable inputs (switches), by changing the material thickness or by pressing the

operator's pedal.After the program (chain) has been processed or after it has been canceled

with the pedal -1 function, processing returns to the first area (start area) of the program

chain (or it switches to another program chain - see Sequences). An editor is available for

creating a welding program, which links the required data records.

The parameter sets P1..P5 are always visible as quick selection buttons. We therefore

recommend that you choose this as the start area of a new program. The other areas are

allocated from the remaining free data records P1..P50 by the editor.

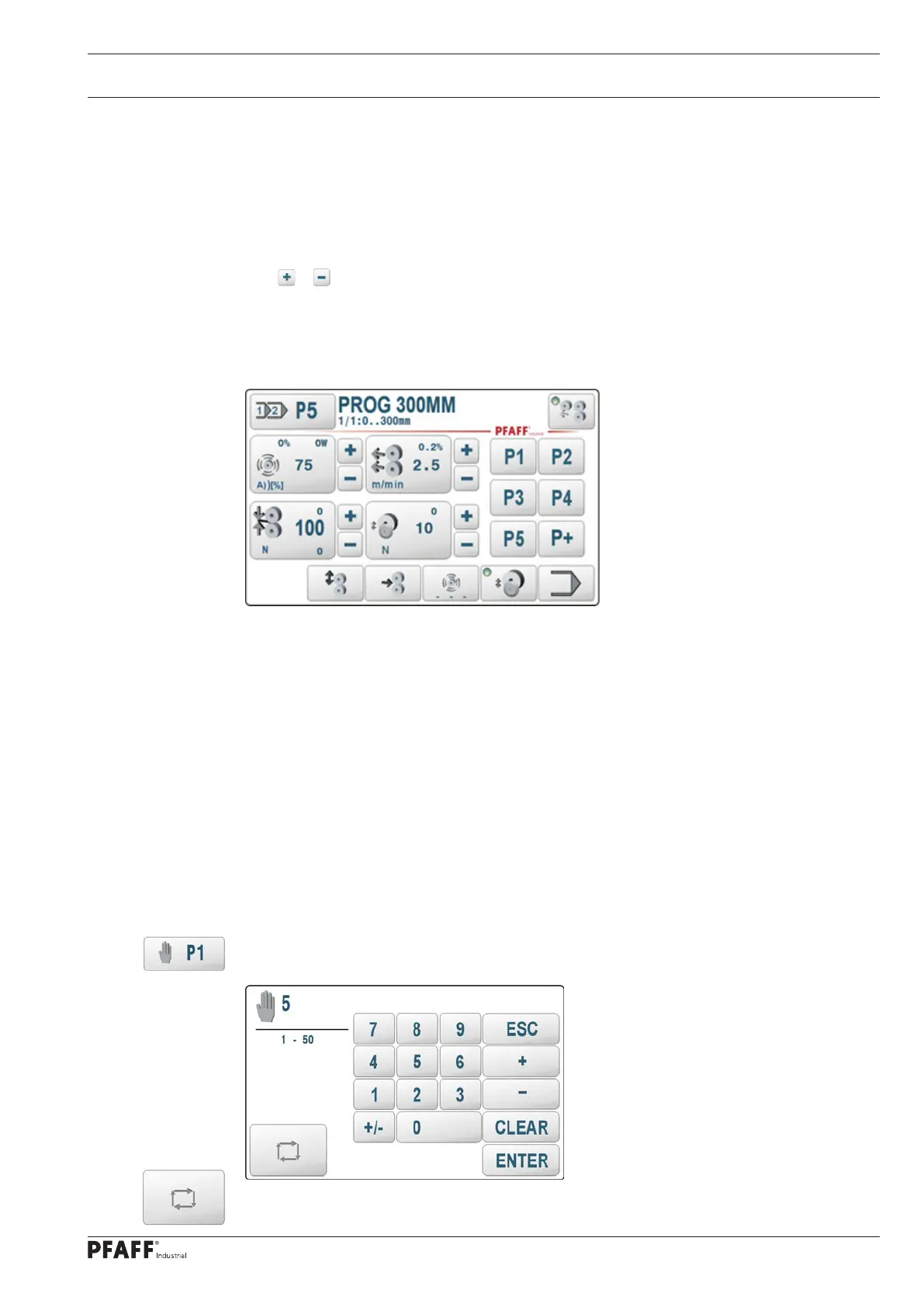

Selection of a start area

Pressing the program number selection touch field opens a new screen for selecting a

welding parameter number P1..P50. We choose any free area (here P5)

Set P5 as the start area of program P5 with the selection key.

Loading...

Loading...