Sealing

36

10.03 Basting

The upright rollers are closed and the ultrasound is switched on briefly during the basting

process. This creates a welding point that fixes the material.

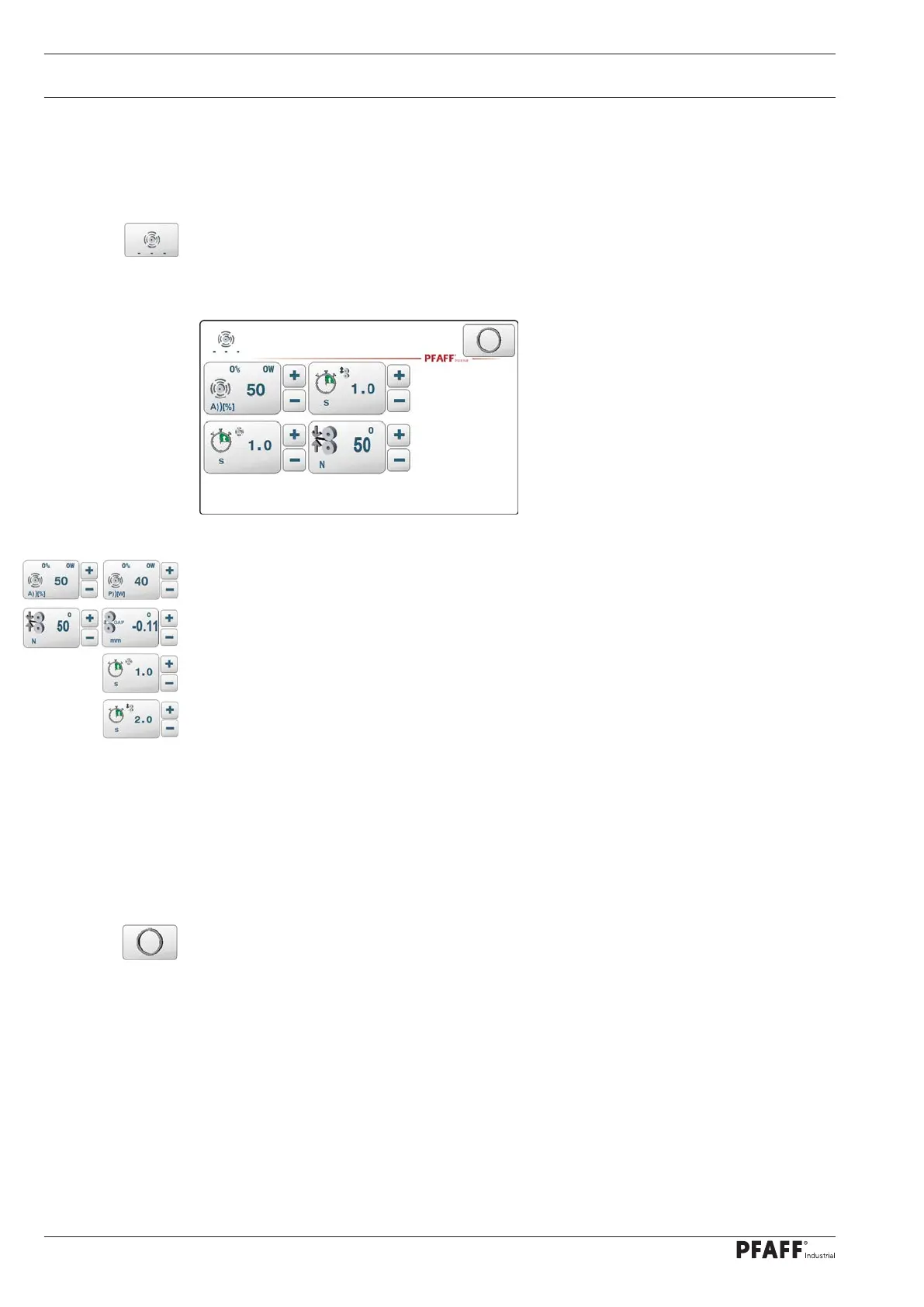

If you press the baste touch field in stop mode, a new screen is opened in which the basting

parameters can be defined. The machine moves the top feed roller to the interme-diate

position. The workpiece is positioned manually. The pe-dal is used to trigger the basting

process.

Parameters:

Enter the ultrasonic amplitude or ultrasonic power

Enter the welding force or roller gap

Enter the switch-on duration of the ultrasound

Enter the holding time

After the basting/welding process has been started with the pedal (Pos2), the top feed roller

moves to the set welding force or the set roller gap. The ultrasound is switched on for the

switch-on duration with the selected amplitude or power. The ultrasound is switched off

again after the switch-on duration has elapsed. The top feed roller remains in the force/gap

position for the set holding time and then moves back up to the intermediate position. The

workpiece is repositioned and the process can be repeated as often as desired.

The end key is used to end the basting process. The machine returns to the previously

selected welding program.

Loading...

Loading...