Sealing

32

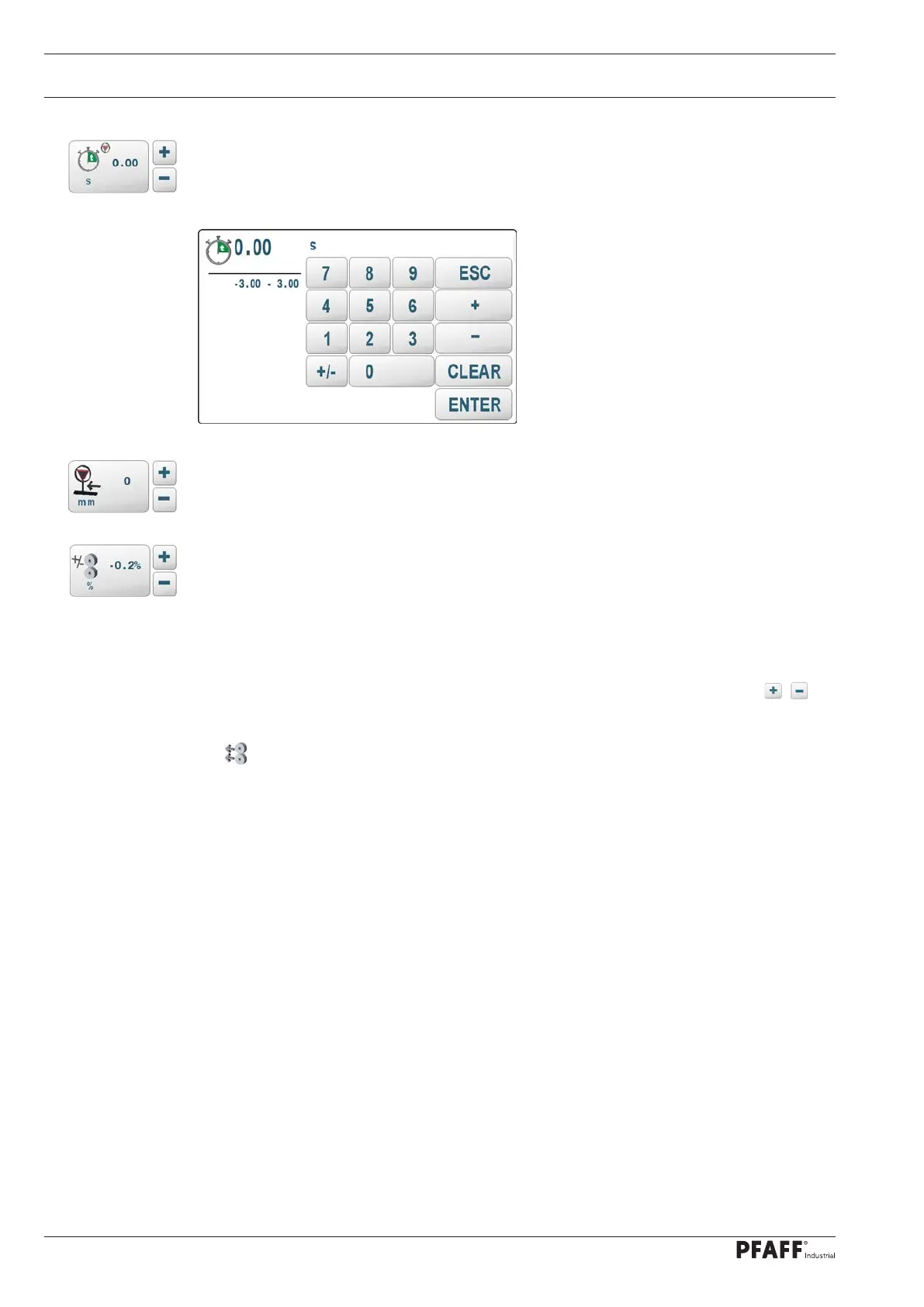

Stop inhibitor

The stop inhibitor, which can take on positive and negative values, defines the switch-off

behaviour. If the stop inhibitor is positive, the ultrasound is switched off and the rollers con-

tinue to run for the set time. With a negative value, the rollers stop im-mediately and the

ultrasound then remains switched on for the set time.

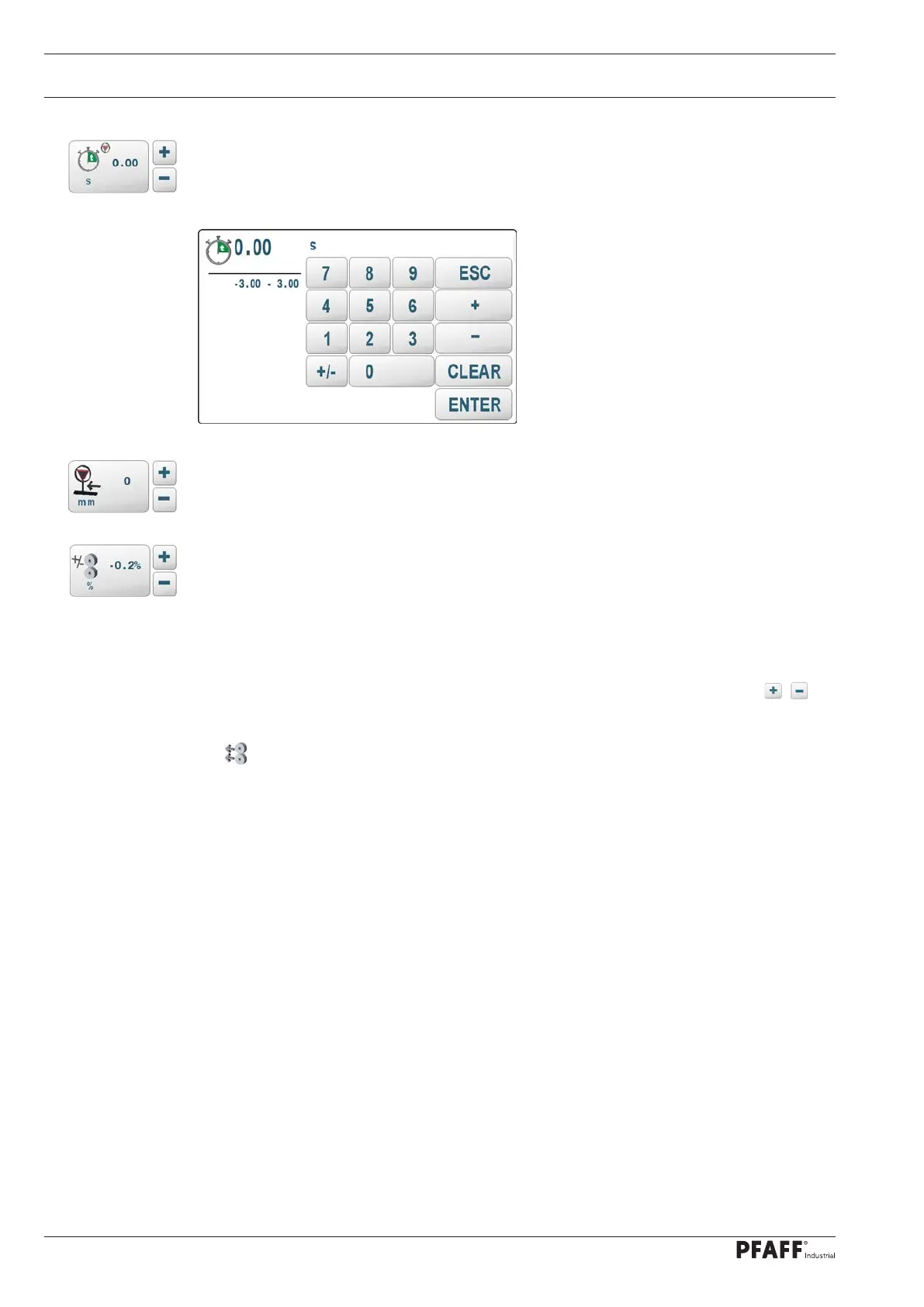

Reverse after stop

After the stop inhibitor has elapsed, this parameter can be used to run back a short distance

so that no gap or double welded section is created when the welding next starts.

Differential

The difference in speed between the top and bottom feed roller can be entered by pressing

the differential key. The bottom feed roller is the guide roller that turns at the set feed roller

speed. The top feed roller can be set at a faster or slower speed. The input is made as a

percentage value. The set differential is displayed above the feed roller speed.

The displayed parameters can be directly increased or decreased in increments with the /

keys.

The key takes you back to the roller speed input menu.

Loading...

Loading...