Sealing

40

10.05.01

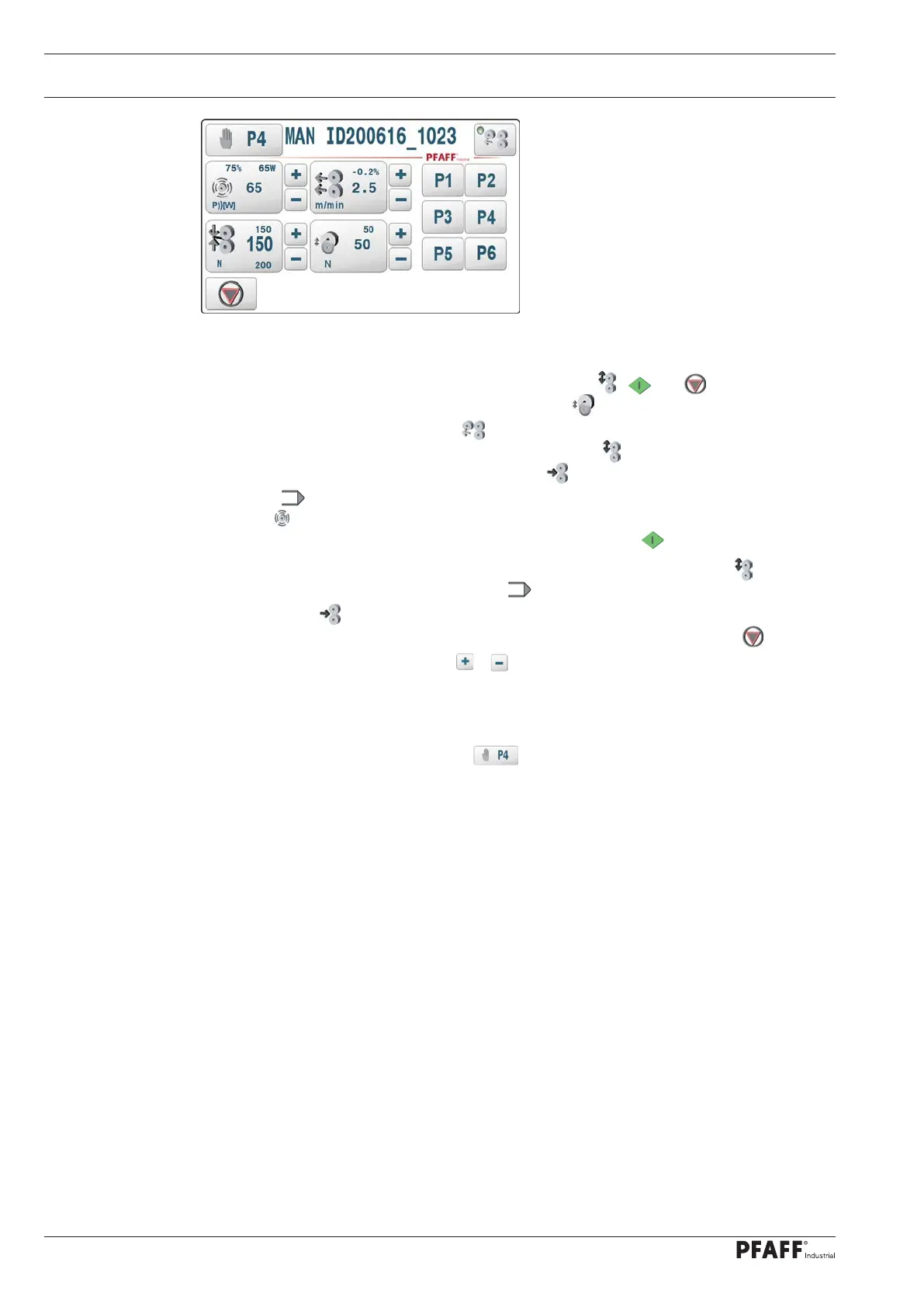

Figure 3: Production, manual sealing mode, sealing process is running.

The welding process is controlled using the pedal and the , and keys. In the DUAL

version, the knife can be switched on and off with the key. If there is a motorised puller,

it can be switched on and off with the key.

The rollers can be closed with the pedal (Pos1) or with the key when the machine is in

the initial state. The roller reverse service function is also available and you can switch to

input mode . The workpieces can be basted together with short welding points using the

baste key .

The welding process can be started with the pedal (Pos2) or the key when the rollers

are closed. Alternatively, the rollers can be opened with the main pedal or the key. It

is possible to switch to input mode with the key or to call up the roller reverse service

function with the key.

The current welding process can be interrupted with the pedal (Pos0/-1) or the key. The

parameters can be changed with the / scroll keys in the current welding process.

In the initial state (with open rollers), the keys P1 .. P6 can be used to select the

corresponding welding parameter data sets directly. Further data sets can be selected with

the program number selection function .

Loading...

Loading...