- If the sealing surface of the valve is found to be

interrupted at one or more points or is not flat, re-

place the valve.

- Insert the valves into the cylinder head.

- Alternatively check the intake and exhaust

valves.

- The test is carried out by filling the manifold with

petrol and checking that the head does not ooze

through the valves when these are just pressed

with the fingers.

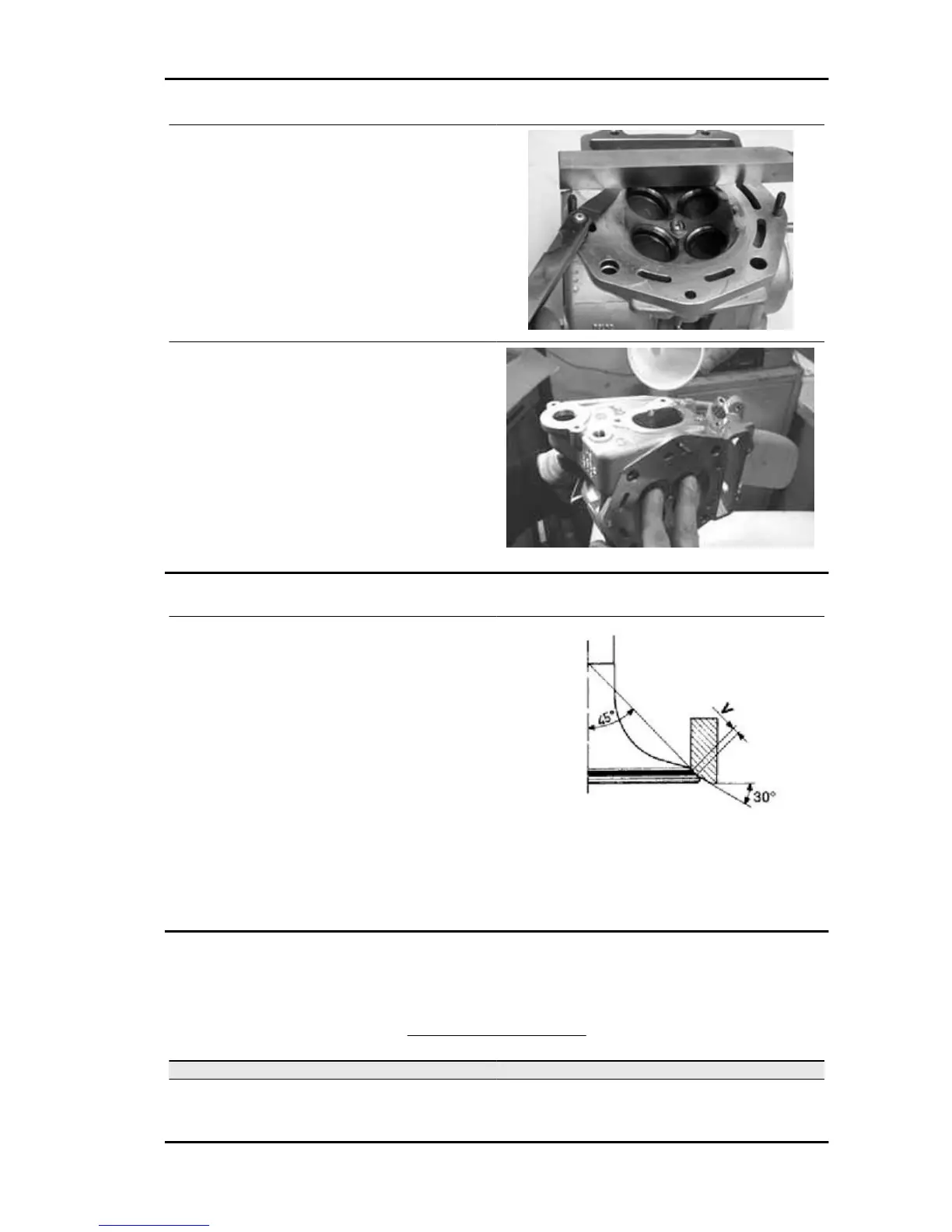

Inspecting the valve housings

- Clean the valve seats of any carbon residues.

- Using the Prussian blue, check the width of the

impression on the valve seat "V".

Characteristic

Standard value:

1 - 1.3 mm

Admissible limit:

1.6 mm

- If the impression width on the valve seat is larger than the prescribed limits, true the seats with a 45°

mill and then grind.

- In case of excessive wear or damages, replace the head.

Inspecting the valves

- Measure the diameter of the valve stems in the three positions indicated in the diagram.

STANDARD DIAMETER

Specification Desc./Quantity

Inlet: 4.987 - 4.972 mm

Outlet: 4.975 - 4.960 mm

MP3 400 i.e. Engine

ENG - 63

Loading...

Loading...