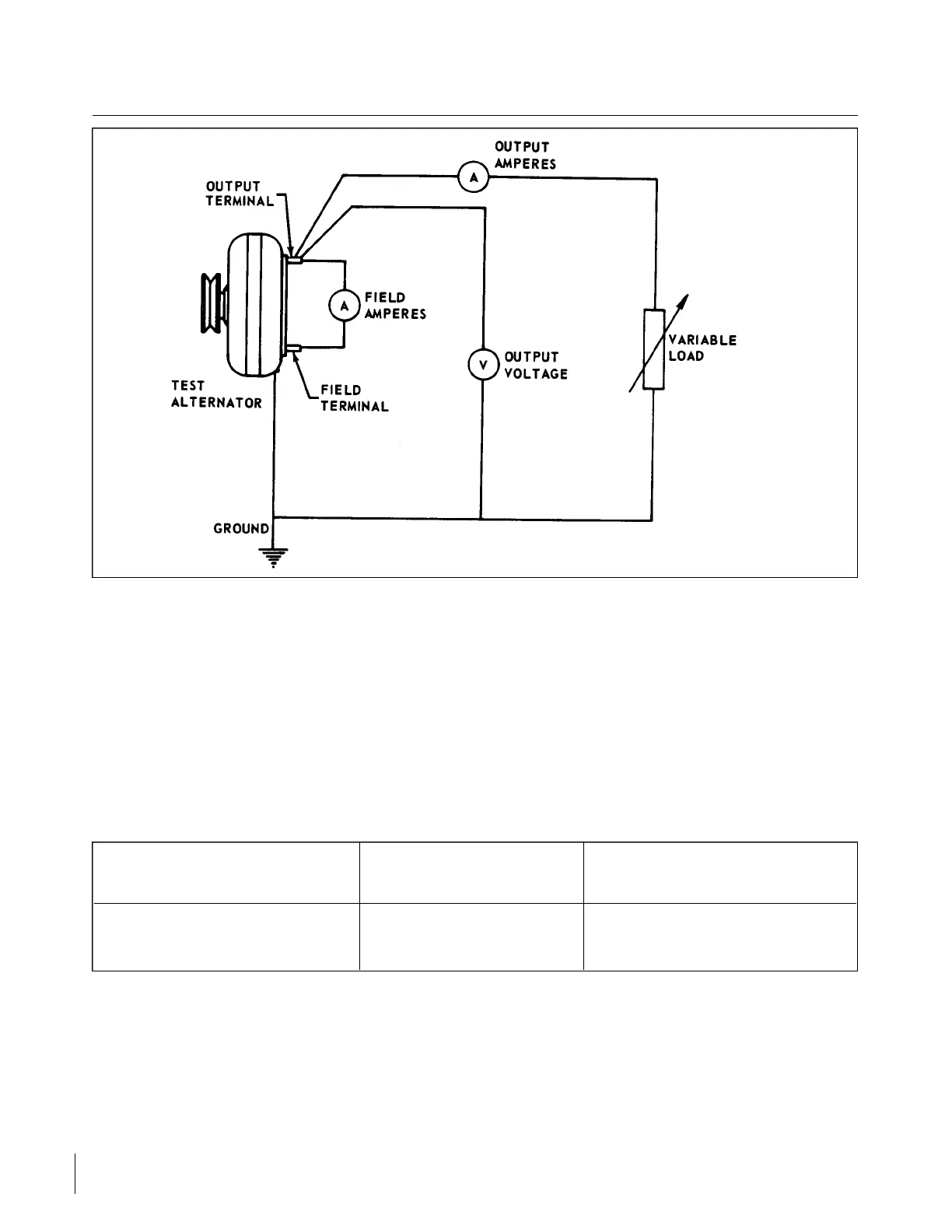

Figure 11-22. Meter Connections for Alternator Performance Test

11-31. CHECK ALTERNATOR BELT TENSION. If properly installed, tensioned and checked periodically,

the alternator drive belt will give very satisfactory service. However, an improperly tensioned belt will wear

rapidly and may slip and reduce alternator output. Consequently, a belt should be checked for proper tension at

the time it is installed, again after 25 hours operation and at each 100 hour inspection thereafter.

The torque method for checking alternator belt tension is given as follows:

a. Apply a torque indicating wrench to the nut that attaches the pulley to the alternator and turn it in a

clockwise direction. Observe the torque shown on the wrench at the instant the pulley slips.

b. Check the torque indicated in step “a” with torque specified in the following chart. Adjust tension

accordingly.

TABLE XI-I. ALTERNATOR BELT TENSION

Torque indicated at

Width of Belt Condition alternator pulley

3/8 inch New 11 to 13 ft.-lbs.

3/8 inch Used 7 to 9 ft.-lbs.

Revised: 2/13/89

2H10

CHEROKEE ARROW III SERVICE MANUAL

ELECTRICAL SYSTEM

Loading...

Loading...