5.17

Engine and Cooling Systems

5

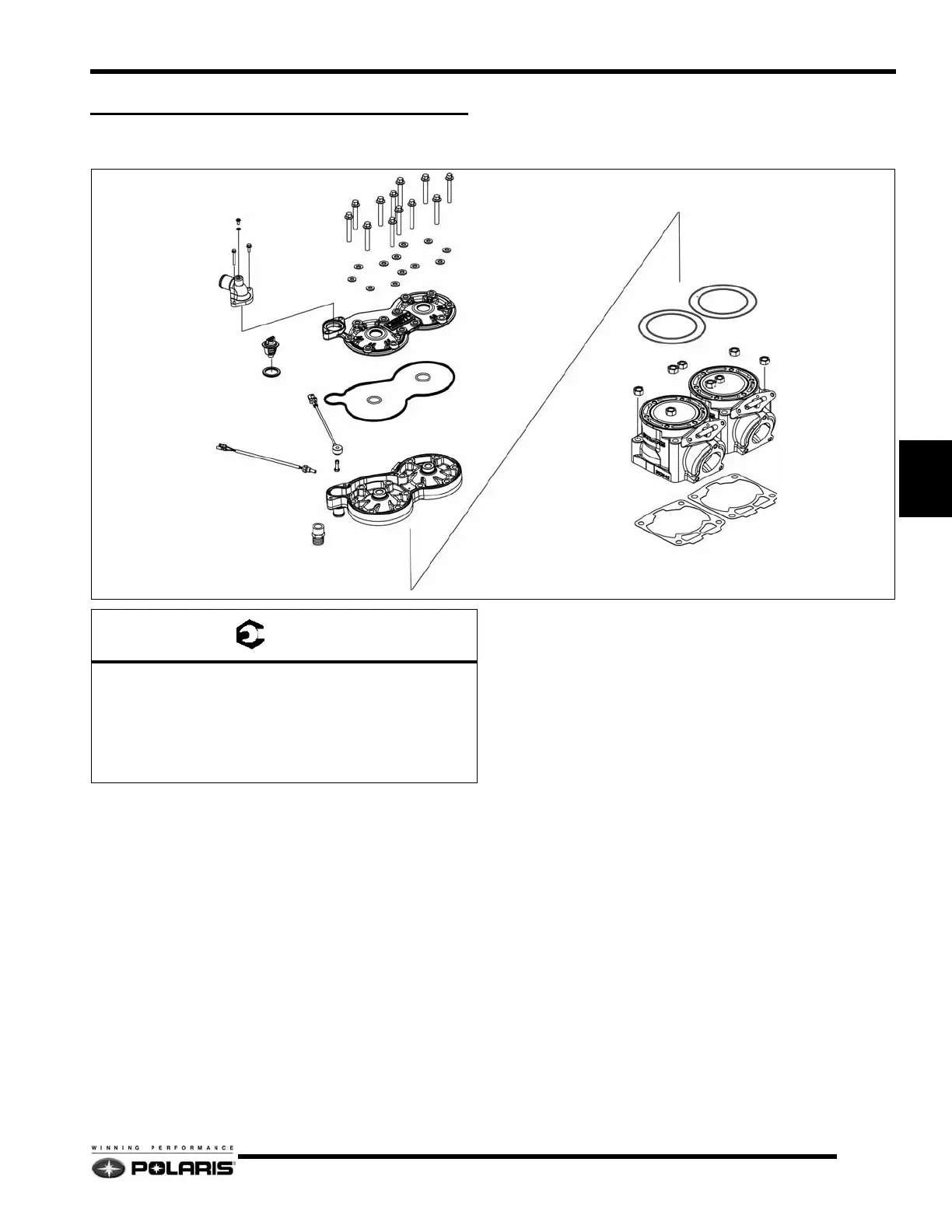

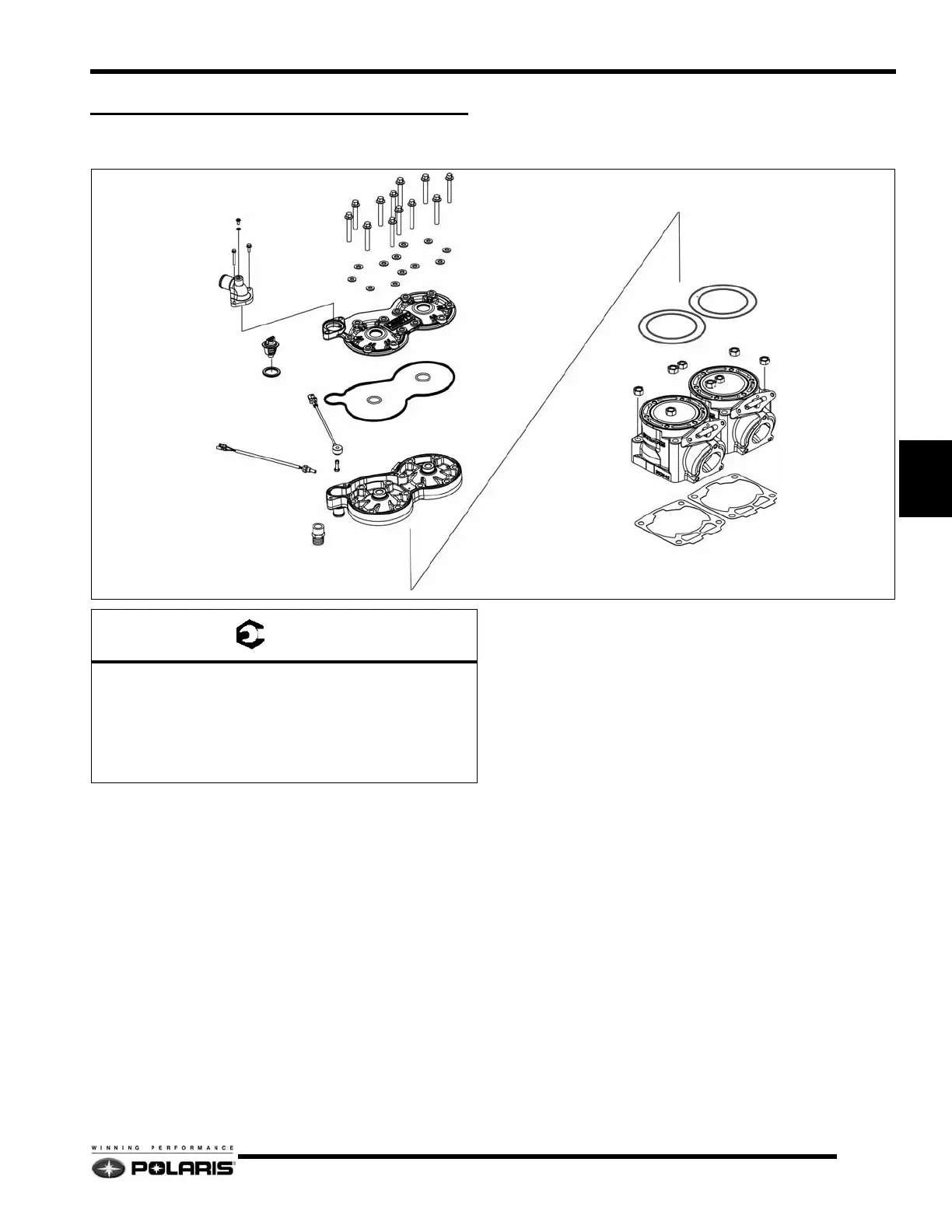

ENGINE COMPONENT ASSEMBLIES

600 HO Carbureted Cylinders / Cylinder Head

Disassembly / Assembly Process

1. Remove the coolant from the engine using a siphon, wet/

dry vac, or drain pan.

2. Remove the air box, exhaust pipe and resonator from the

engine compartment.

3. Remove the high tension wires and spark plugs from the

cylinder head.

4. Remove the thermostat housing outlet cooling hose from

the housing.

5. Loosen all, then remove all head cover fasteners. Clean the

fastener threads to remove any thread locking residue.

6. Discard the head cover and cylinder head o-rings. Always

use new o-rings during assembly.

7. Inspect the cylinder head / combustion domes for any

damage. Measure cylinder head flatness. Replace cylinder

head if required.

8. Loosen all, then remove the cylinder bolts. Clean the bolt

threads to remove any thread locking residue.

9. Carefully pull each cylinder upwards taking care not to

drop the piston and rod abruptly against the crankcase.

10. Remove the cylinder base gaskets. Use a gasket scraper to

clean the gasket residue from the crankcase and cylinder

bases.

11. Inspect the cylinder walls. Nicasil cylinders can only be

lightly honed. Damage that cannot be removed with a light

hone requires cylinder replacement or re-lining.

12. The assembly process is the reverse of disassembly.

13. Always use new gaskets and o-rings during assembly.

Liberally coat the inside of each cylinder and the outside

of each piston with Polaris two-stroke engine oil.

14. When installing a piston into a cylinder, verify each piston

ring opening is located at each piston ring locating pin.

Squeeze the top ring, then carefully slide the cylinder over

the compressed ring. Do the same with the bottom ring.

15. Follow the torque specifications and torque sequences

located at beginning of chapter when tightening fasteners.

HEAD COVER

WASHERS

CYLINDER HEAD O-RINGS

CYLINDERS

CYLINDER BASE GASKETS

CYLINDER HEAD

HEAD COVER O-RINGS

THERMO SENSOR

KNOCK SENSOR

THERMOSTAT

GASKET

THERMOSTAT

HOUSING

BLEED SCREW

A

B

C

D

E

F

= T

A = 70 In.Lbs. (8 Nm)

B = 9 Ft.Lbs. (12 Nm) - Apply Loctite 242

C = 25 Ft.Lbs. (34 Nm) - Apply Loctite 242

D = 18 Ft.Lbs. (24 Nm) - Apply Pipe Sealant

E = 168 In.Lbs. (19 Nm) - Clean and Dry

F = 37 Ft.Lbs. (50 Nm)

Loading...

Loading...