4.30

Fuel Systems

Fuel Tank Pressure Test

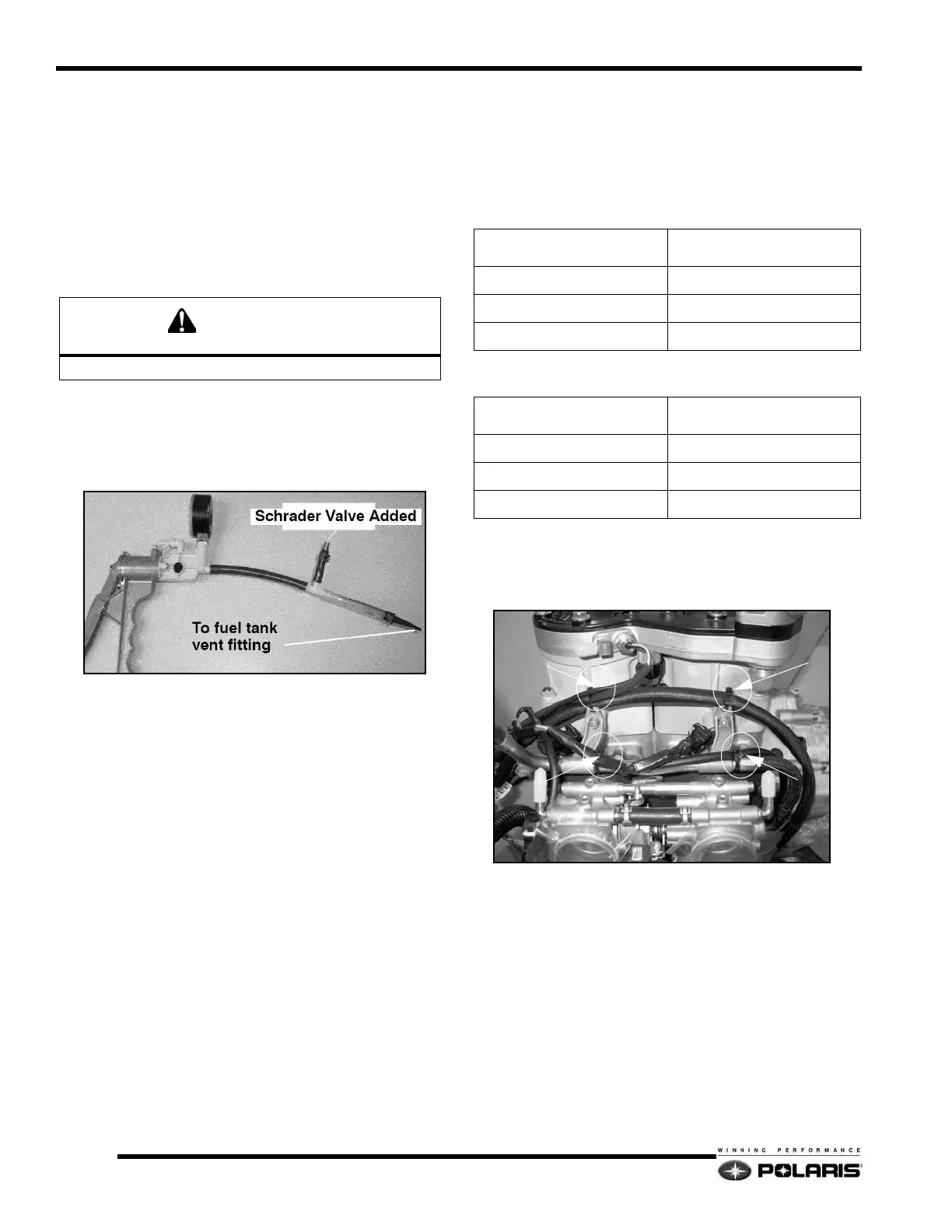

1. Connect a Mity Vac hand pump to the fuel tank vent

fitting.

2. Connect a eight-inch piece of 5/16

″ fuel hose and two gear

clamps across the fuel supply and return fittings at the fuel

pump flange.

3. Pressurize the tank to 5 PSI.

NOTE: Fuel tank deformation will occur when the

tank is pressurized.

NOTE: Using a hand pump to pressurize the fuel

tank may take a very long time. The installation of an

in-line Schrader Valve (PN: 2872602) and the use of a

low pressure pump (bicycle tire pump) is

recommended.

4. Once the tank is pressurized, saturate the area around the

PFA gasket with a mixture of water and mild detergent.

5. If any bubbles form, re-check the PFA nut torque. If bubble

formation continues, the PFA gasket will have to be

replaced, or tank replacement is required.

NOTE: There may be bubbles present from the initial

application of leak detector. Slightly blow on the

bubbles to pop them. Watch for new bubble

formation. New bubble formation may very small so

look closely. Apply additional water/detergent

solution if required.

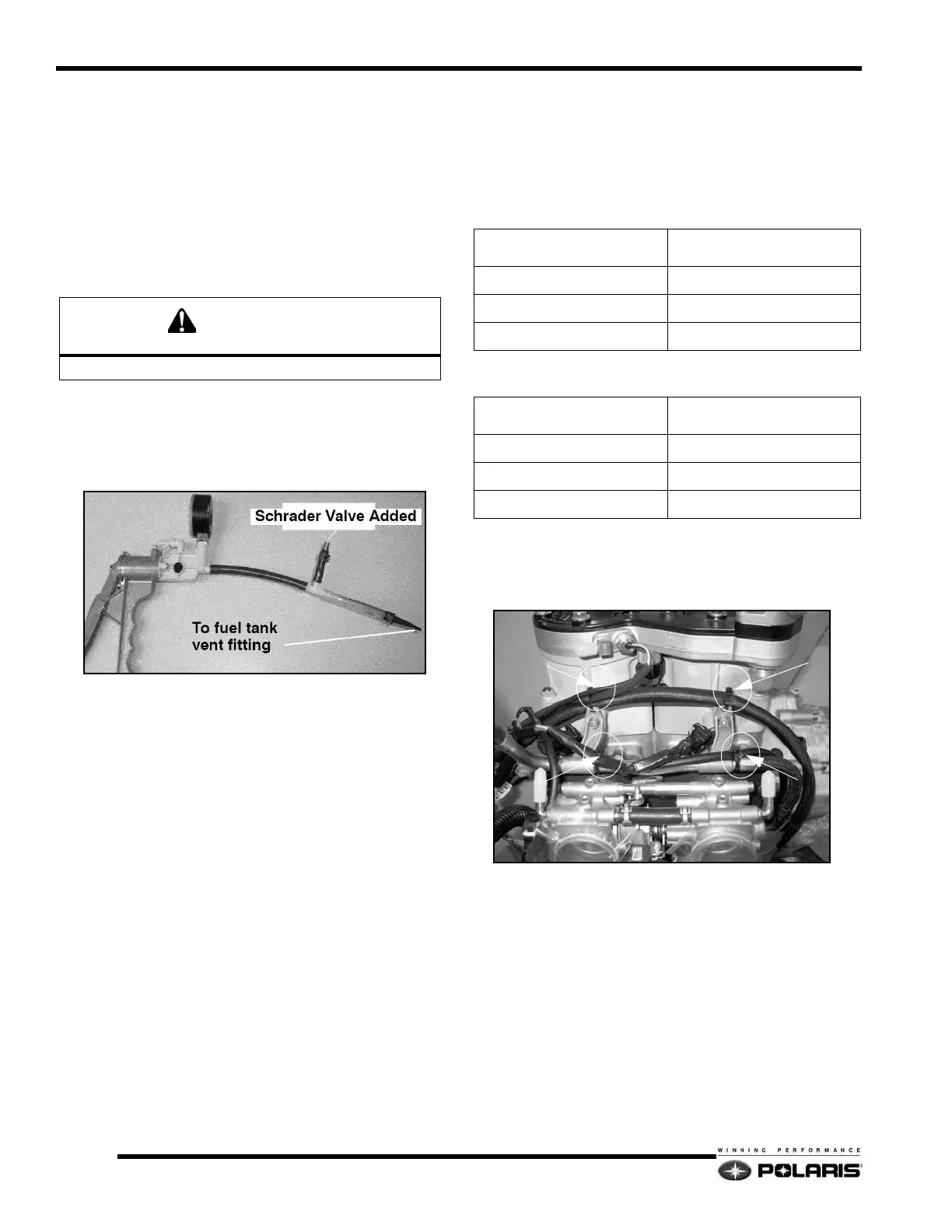

CFI Fuel Rail/Injector(s) Removal/Installation

NOTE: Keep the red protective cap on the end of the

injector to prevent damage when installed. Follow

the steps and remove when instructed to do so.

1. Depressurize the fuel rail. See “Fuel Rail Bleeding /

Pressure Testing” on page 4.29.

2. Remove the panduit straps as shown.

NOTE: The engine must be removed from the engine

compartment to access the lower two fuel injectors.

WARNING

Do not over-pressurize the fuel tank past 6 PSI.

600 / 700 CFI INJECTOR KITS

INJECTOR KITS

COLOR

2203325-053 Yellow

2203325-027 Blue

2203325-015 Red

800 CFI INJECTOR KITS

INJECTOR KITS

COLOR

2203575-053 Yellow

2203575-027 Blue

2203575-015 Red

Loading...

Loading...