9.17

Shocks

9

5. After all of the nitrogen gas has been allowed to escape

from the shock, remove both pressure valve assemblies.

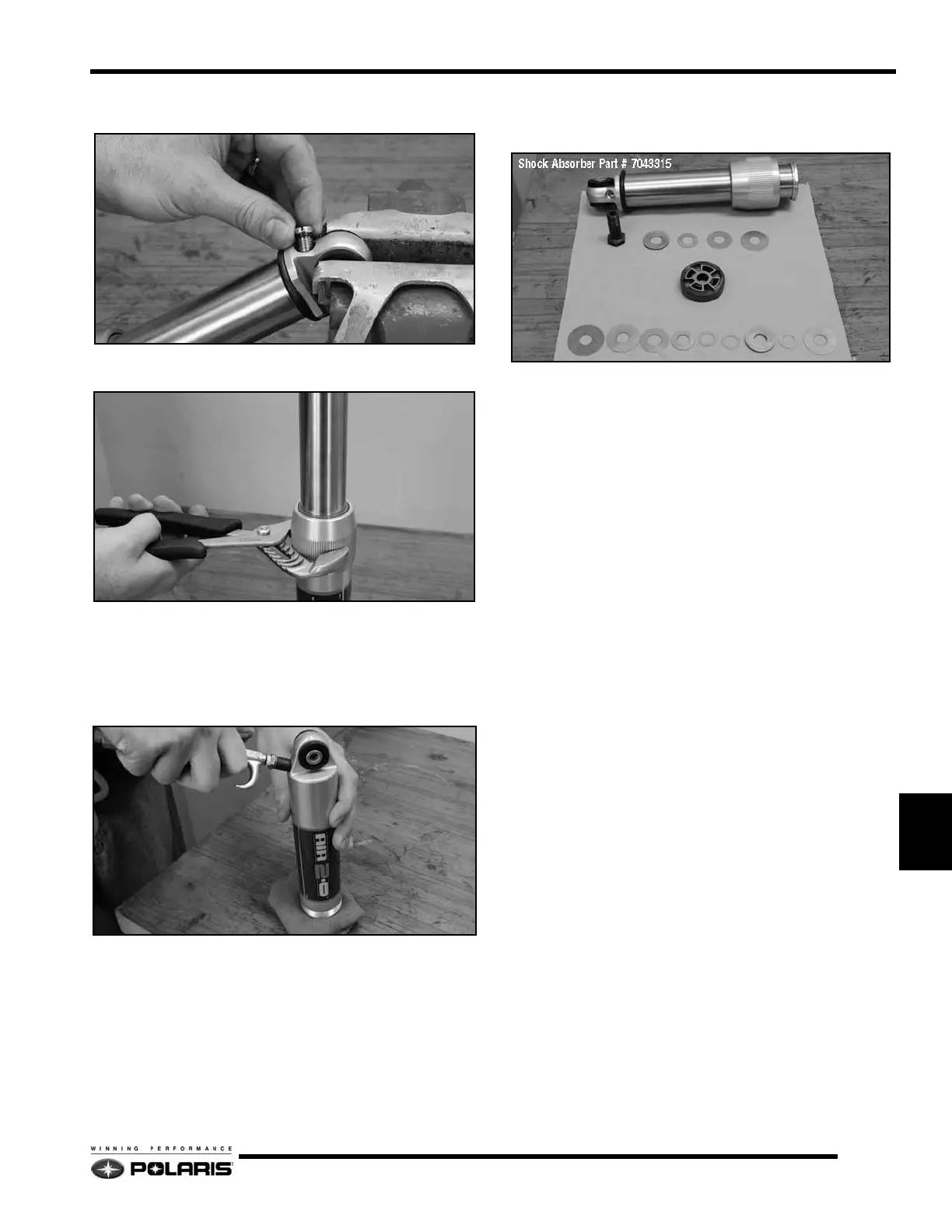

6. Using interlocking channel pliers, loosen and remove the

cylinder head assembly.

7. Pour the oil out of the cylinder. Discard oil into an approved

container and dispose appropriately. Never reuse shock oil.

8. Using compressed air, invert the large diameter cylinder

over a clean shop towel. Pressurize the cylinder to 90 psi

to remove the IFP from the cylinder. Account for the

floating piston, wear band, and o-ring.

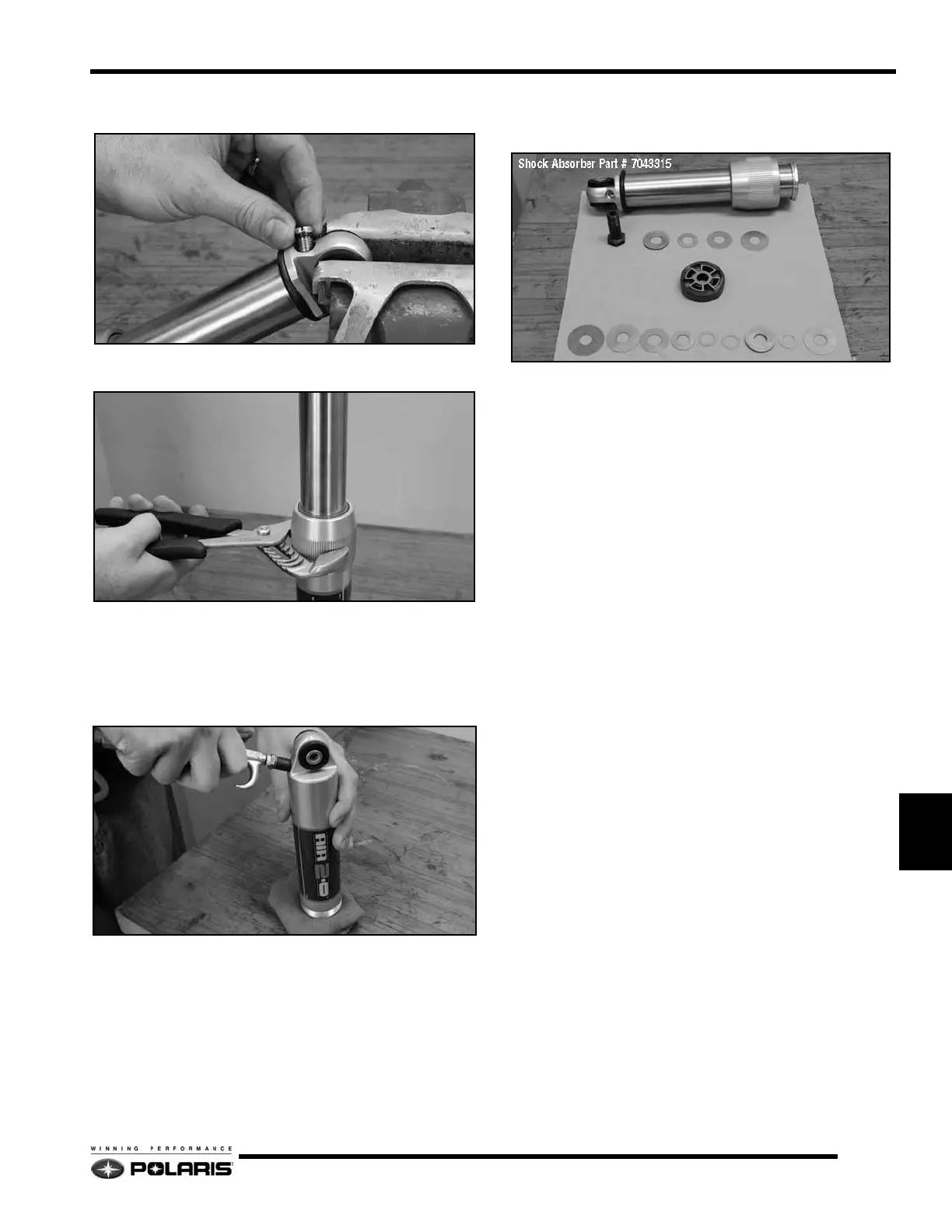

9. Place the 36mm piston (shock) rod upper mount in a soft-

jawed bench vise. Remove the piston valve and valve shim

assembly from the rod in the sequence of disassembly.

10. Remove the rod head assembly and spring from the rod

shaft.

11. Again, using compressed air, invert the rod shaft over a

clean shop towel. Pressurize the cylinder to 90 psi to

remove the IFP from the cylinder. Account for the floating

piston and o-ring.

12. With the shock disassembled, inspect the following items:

• 36mm piston rod for straightness, nicks, or burrs.

• Cylinder head assembly / bearing.

• Inside of shock body for scratches, burs, or excessive

wear.

• Teflon piston and IFP wear band for cuts, chipped or

nicked edges, or excessive wear.

• O-rings for nicks, cuts, or cracks.

• Valve discs for kinks or waves.

Loading...

Loading...