THE ART OF WELDING

P6

50-92 PN-0509076 Rev. 16

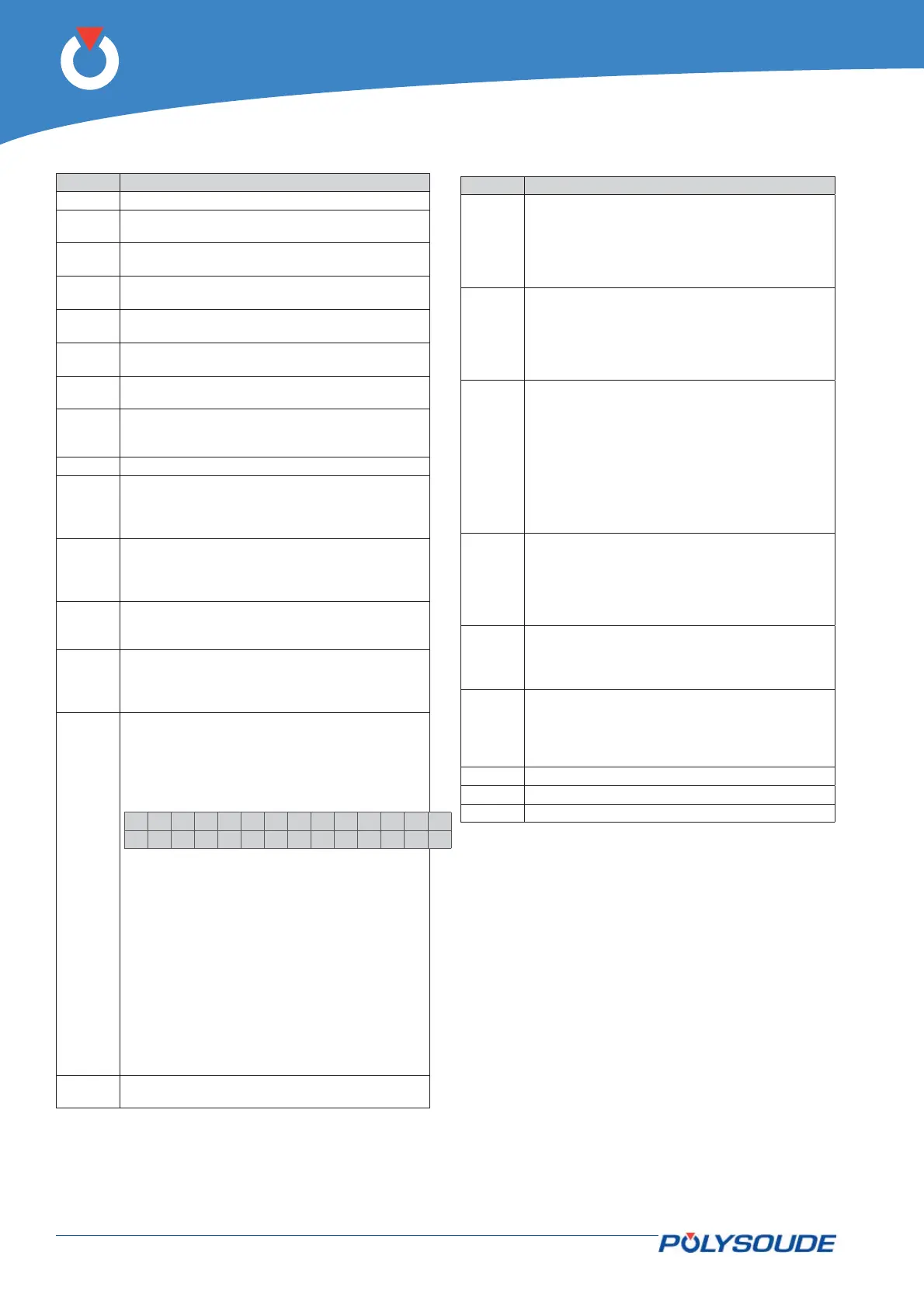

Remote control pendant 4 axis 00261491014. 5. 5.

Function of operating elements

Pos Designation

AF 1 2 line 16 character backlight display.

V 1 Red indicator illuminated: Simulation without

arc.

V 2 Green indicator illuminated: Weld mode with

arc.

V 3 Green indicator illuminated: Increment actions

on low level.

V 4 Green indicator illuminated: Increment actions

on high level.

V 3+

V 4

Green and red indicator illuminated: Increment

actions on low and high level.

V 5 Red indicator illuminated: fi ller wire operation

during weld cycle controlled by BT 10.

V 6 Green indicator illuminated: automatic fi ller

wire operation according to programmed pa-

rameters.

BT 1 Push button for line toggling on the display.

BT 2 Push button to move down in the WP or pro-

gram list or to decrease a numeric value. After

1 s of continued pushing, the automatic mode

is applied.

BT 3 Push button to move up in the WP or program

list or to increase a numeric value. After 1 s

of continued pushing, the automatic mode is

applied.

BT 4 Push button to toggle between simulation

without arc and weld mode with arc (associated

with V 1 & V 2).

BT 5 Push button to toggle between increment ac-

tions on low level, increment actions on high

level or increment actions on both levels (as-

sociated with V 3 & V 4).

BT 6

Out cycle : Press the button BT 6 “I-” of

the remote control pendant during several

seconds.

On the display of the remote control

pendant appears:

>IPAdress

Tacho

Select “IP Adress” with the button BT 1.

Confi rm the selection with the button

BT 3 “N+”.

Modifi cation of the IP address. The IP ad-

dress is in the form of four numeric blocks

that can be modifi ed by BT 2 and BT 3.

Moving from one block to another is effected

by a pulse on BT 1. Once you have reached

the last block, pressing once more on BT 1

stores the new entry in memory and termi-

nates the IP address modifi cation procedure

During a weld cycle: Decrementation of the

weld current level selected with BT 5.

BT 7 During a weld cycle: Incrementation of the weld

current level selected with BT 5.

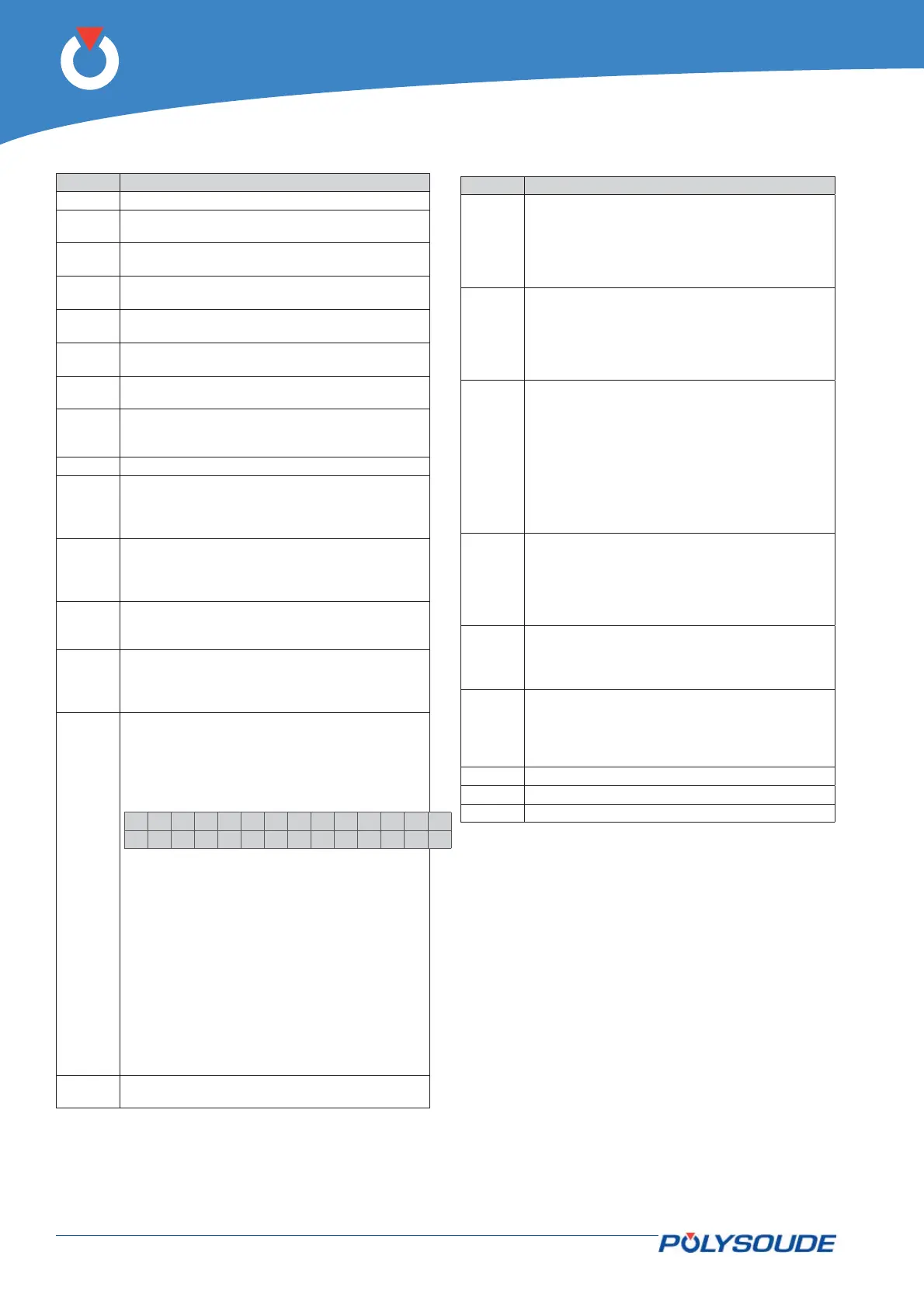

Pos Designation

BT 8 Push button operating in two modes:

Out of cycle: Manual rotation rearwards at low

speed during 1 s, at medium speed during 2 s,

afterwards at full speed.

During a weld cycle: Decrementation of the

rotation speed level selected with BT 5.

BT 9 Push button operating in two modes:

Out of cycle: Manual rotation forwards at low

speed during 1 s, at medium speed during 2 s,

afterwards at full speed.

During a weld cycle: Incrementation of the

rotation speed level selected with BT 5.

BT 10 Push button operating in two modes:

Out of cycle in automatic mode (V 6 illumi-

nated): Manual wire feeding forwards at low

speed during 1 s, at medium speed during 2 s,

afterwards at full speed.

Out of cycle in manual mode (V 5 illuminated):

The fi rst touch starts wire feeding at high

speed, the second touch stops it.

During a weld cycle: Incrementation of the wire

feeding speed level selected with BT 5.

BT 11 Push button operating in two modes:

Out of cycle: Manual wire feeding rearwards at

low speed during 1 s, at medium speed during

2 s, afterwards at full speed.

During a weld cycle: Decrementation of the

wire feeding speed level selected with BT 5.

BT 12 Push button to toggle between the automatic

wire feeding mode (indicator V 6 illuminated)

or the manual wire feeding mode (indicator V 5

illuminated).

BT 13 Push button operating in two modes:

Out of cycle: coolant pump, gas 1 and gas 2

commands.

During a weld cycle: Manual cycle stop with

downslope.

BT 14

Push button “Start cycle with restart”.

BT 15 Push button "Start cycle".

BT 16 Push button "Stop cycle immediately".

Loading...

Loading...