THE ART OF WELDING

P6

PN-0509076 Rev. 16 67-92

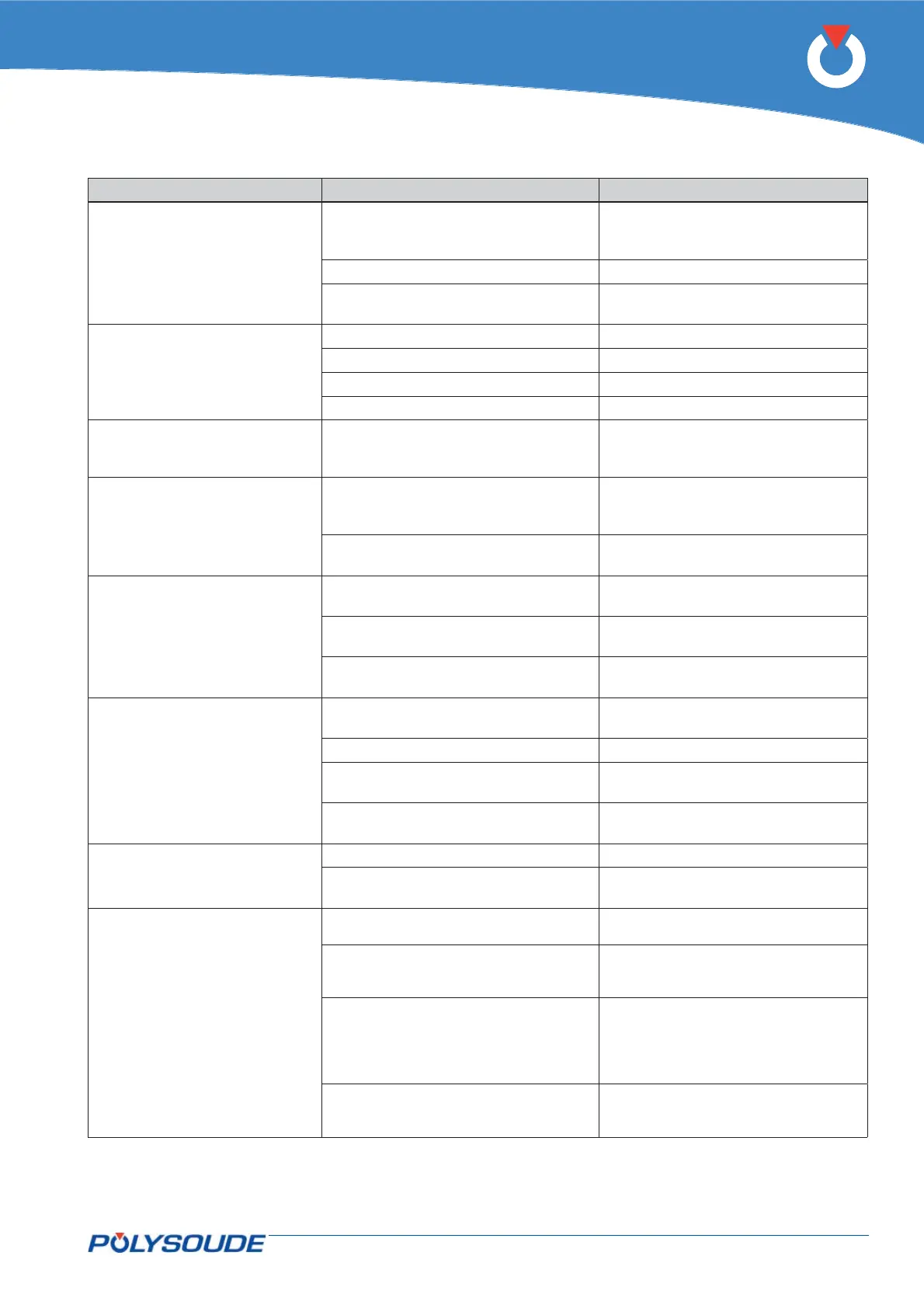

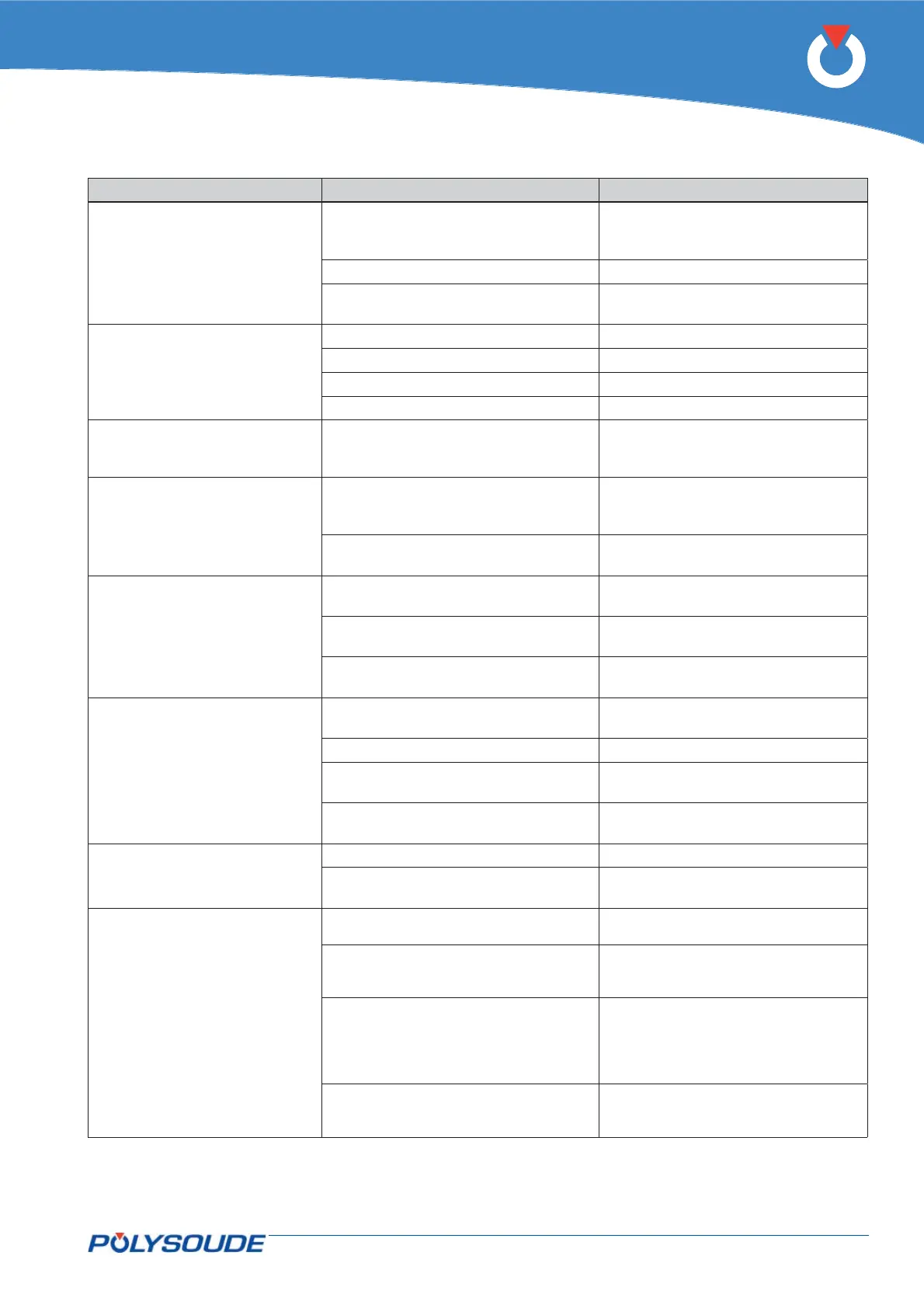

Problem (Consequence) Possible causes What to do

Overheating

(Stop immediately)

Air circulation blocked

Respect a minimal distance between

the openings and any surface (§

4.2.2), let the source cool down

Power source capacity exceeded Modify conditions of use

Fan failure

Must be checked and, if necessary,

replaced by a qualifi ed electrician

Source control

(Stop immediately)

Mains supply voltage too low Correct or modify the connection

Polygaine defect (MU welding heads) Replace

Power source badly adjusted Contact Polysoude After Sales Service

Current source defect Contact Polysoude After Sales Service

Rotation or wire feed control

(Stop or imposed downslope)

Sticky mechanics of the head or the

wire feed unit

Clean

Check for foreign bodies inside the

head or wire feed unit

Overcurrent rotation or wire feed

(Stop immediately)

Sticky mechanics of the head or the

wire feed unit

Clean

Check for foreign bodies inside the

head or wire feed unit

Power source converter card

0028019100 defect

Replace

Rotation or wire feed pulse sen-

sor

(Stop immediately)

Wire feed unit or head sensor dam-

aged

Replace

Connection cable with the power

source damaged

Must be checked and, if necessary,

replaced by a qualifi ed electrician

Power source converter card

0028019100 defect

Replace

Manual downslope

(Imposed downslope)

The power source is not connected to

the earth

Correct

Remote control defect Check

Cable shielding of the remote control

damaged

Replace the cable

Remote control card 0028049100

defect

Replace

Manual stop

(Stop immediately)

Remote control defect Replace

Remote control card 0028049100

defect

Replace

End stop fault on oscillation/ Arc

height or touched part fault.

(Stop immediately)

Surface of the workpiece in poor con-

dition.

Improve the surface if it is possible

Connections on the +/- plugs are

wrong and arc voltage measurement on

the power source U

arc

is wrong too.

Connect properly and check

Voltage between workpiece and elec-

trode less than 0.3 V when not welding

Check whether the voltage between

electrode and workpiece is higher

than 0.3 V when not welding. If not,

contact Polysoude After Sales Serv-

ice.

37 pin front connector (arc height/os-

cillation) not connected or cable dam-

aged (item FA 27 in § 4.4.1.).

Correct modify connections or change

the cable if it is damaged.

Loading...

Loading...