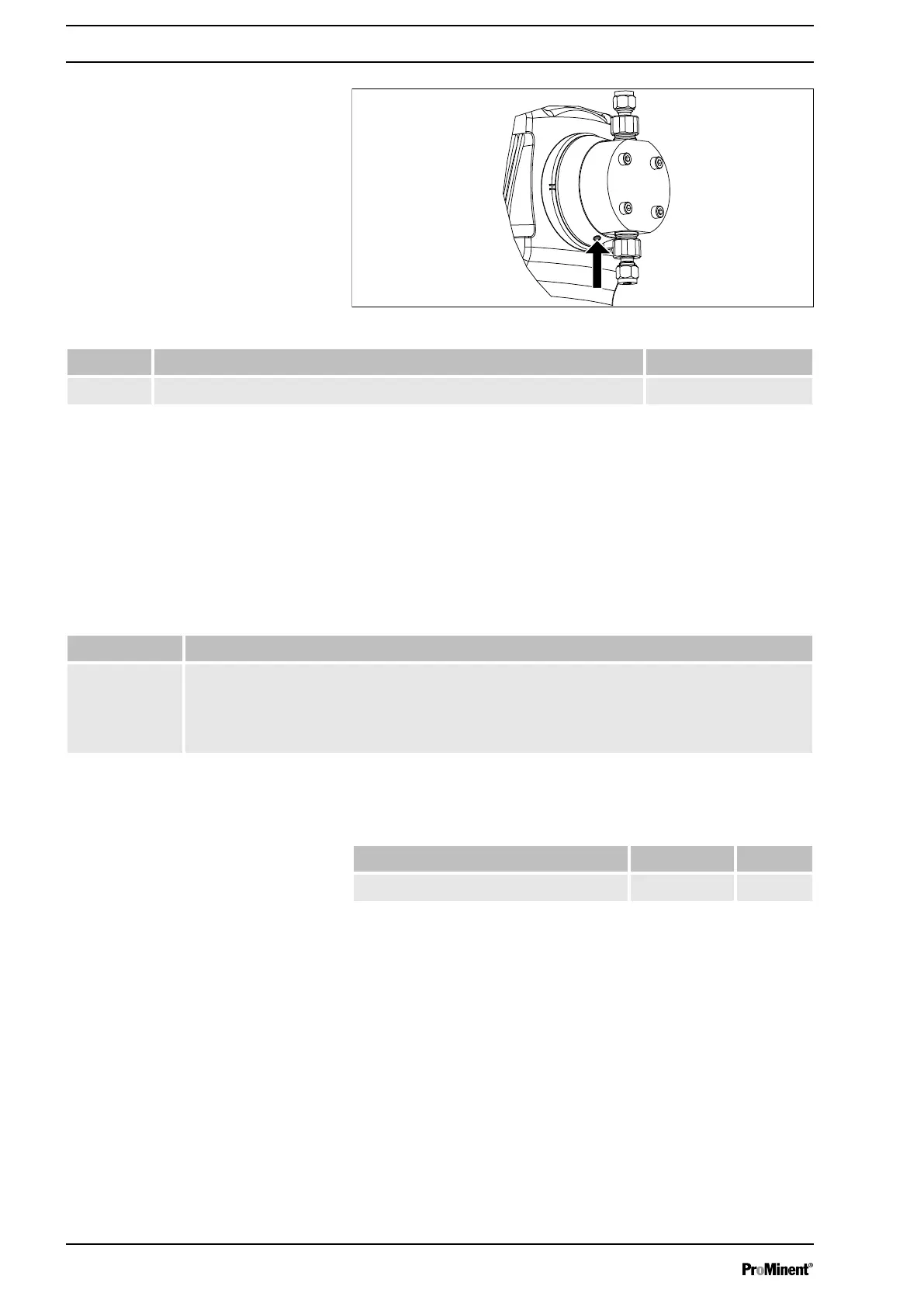

Fig. 39: The leakage hole

Interval Maintenance work Personnel

Annually*

n Check the diaphragm for damage - refer to "Repair"

Technical personnel

* Under normal loading (approx. 30% of continuous operation).

Under heavy-duty loading (e.g. continuous operation): Shorter

intervals.

Check the metering diaphragm more frequently or use a dia‐

phragm rupture indicator with feed chemicals that put particular

pressure on the diaphragm, e.g. those containing abrasive addi‐

tives.

Interval Maintenance work

Quarterly*

n Check that the bypass line is fixed firmly to the liquid end.

n Check that the bleed valve is tight.

n Check the discharge and bypass line for kinks.

n Check that the bleed valve is operating correctly.

* Under normal loading (approx. 30% of continuous operation).

Under heavy loading (e.g. continuous operation): Shorter intervals.

Data Value Unit

Tightening torque for screws: 4.5 ... 5.0 Nm

Liquid ends with bleed valve - addi‐

tionally:

Tightening torque

Maintenance

100

Loading...

Loading...