5-2

ROTALIGN 01.2000

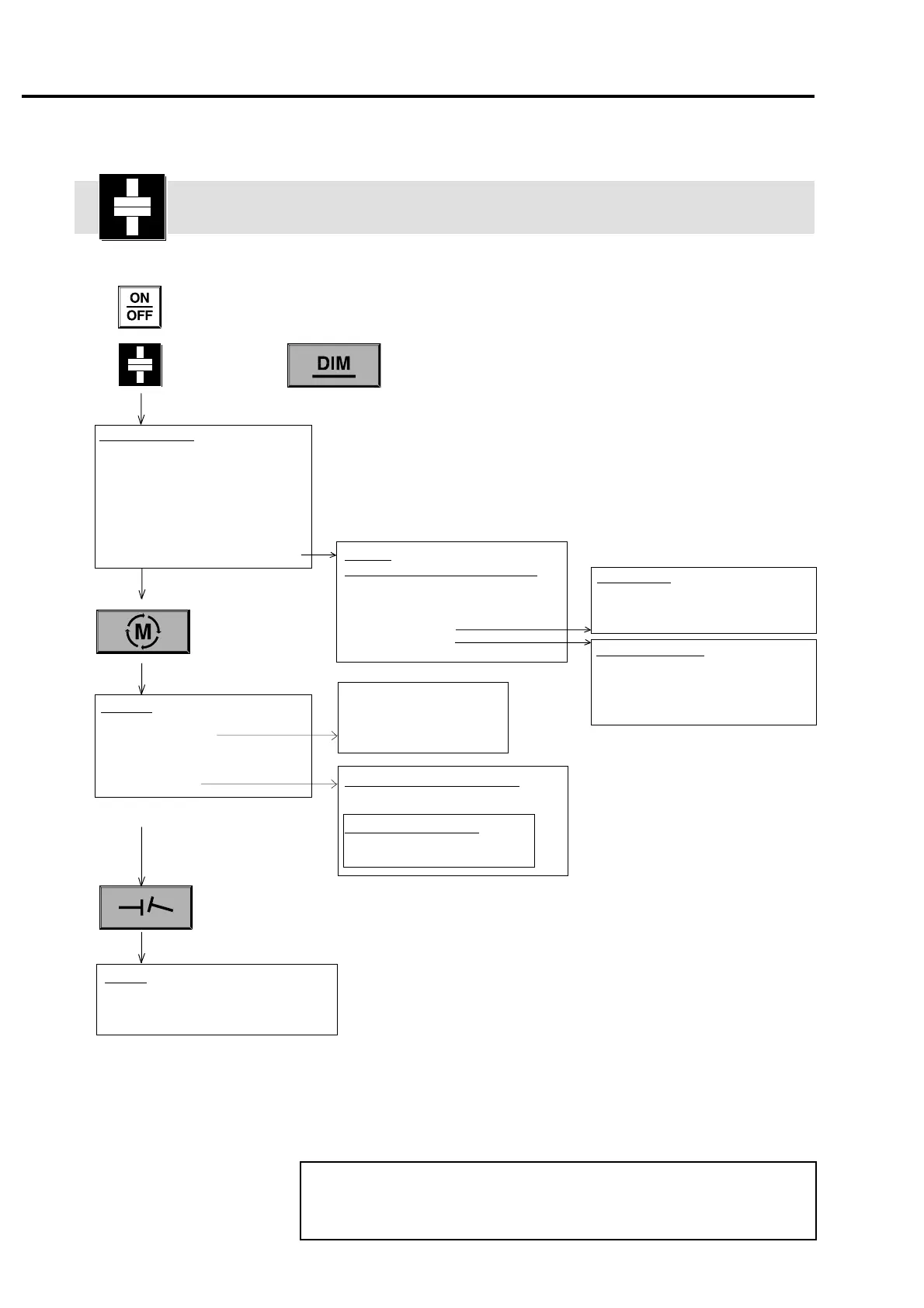

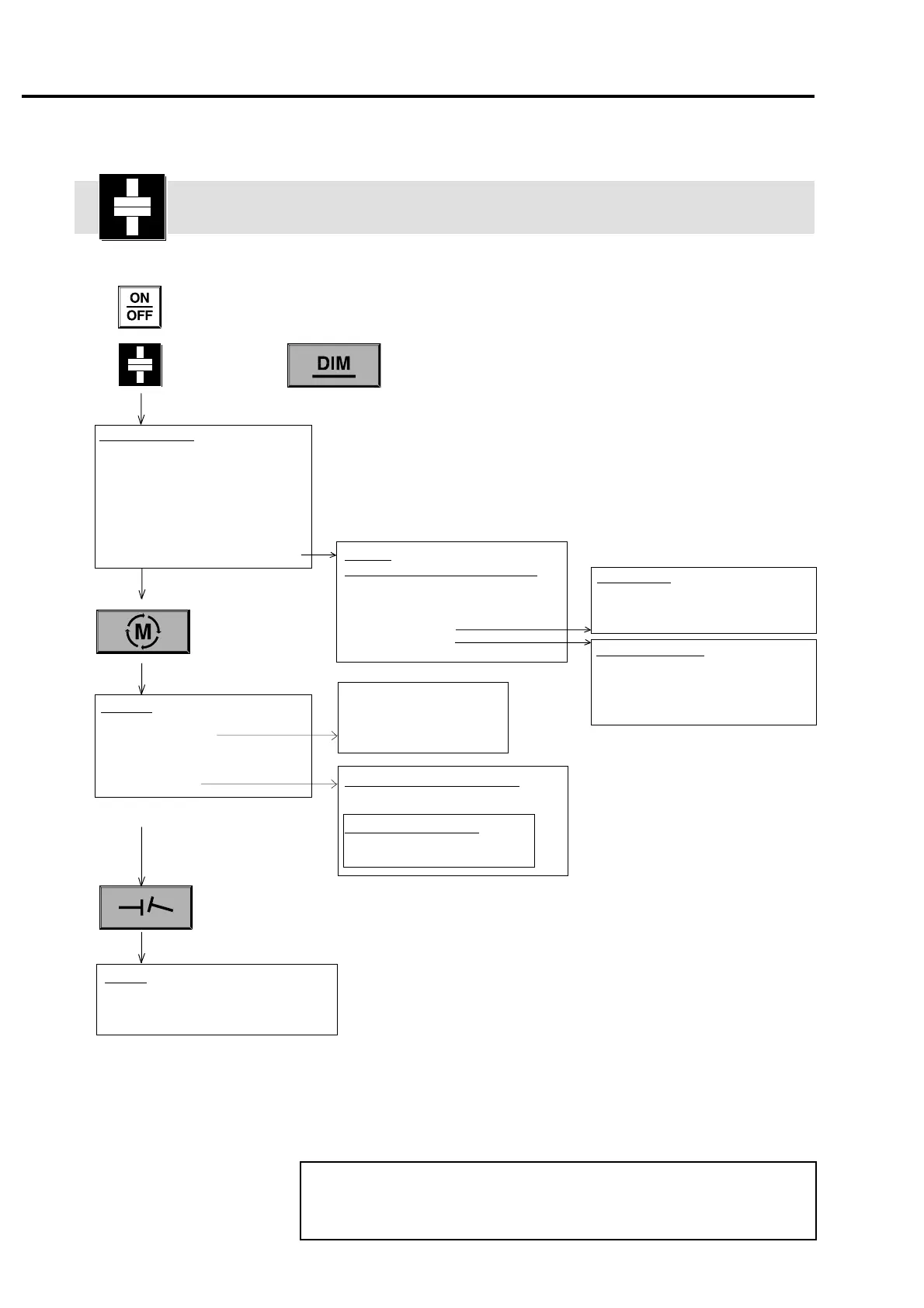

Vertical machine alignment flow chart

Vertical machine alignment flow chart

Edit dimensions (page 5-5)

NEW MACH

NUMBER BOLTS

EDIT:

Bolt distance

Flange diameter

Coupling center to receiver

CIRCLE/SQUARE

OPTION (nonsymmetrical setup) :

To review

dimensions

later press:

OPTION (page 5-11)

Edit nonsymmetrical dimensions

NORMAL ORDER

(clear and return to symmetrical)

EDIT (X-axis, Y-axis, etc.)

ADJUST CENTER:

EDIT BOLTS:

Edit bolt positions

Up, Down (select bolt from list)

EDIT X-POS, EDIT Y-POS (move bolt)

DELETE (delete bolt)

OK returns to previous menu

Move center

Up, Down, Left, Right

STEP SIZE: small, med., large, XL

OK returns to previous menu

Results (page 5-9)

SAVE (page 3-6)

+/-, -/+, 0/+ (+ve/-ve shim calculations)

MOVE (press START, then STOP)

Measure (page 5-6)

TABLE (page 4-48)

XY VIEW (page 4-43)

Arrow selects point

CLR key deactivates selected point

MEAS. MODE:

Vertical and horizontal shafts:

Measure at 1, 2, 3, 4, 5, 6, 7, 8 (5-6)

Horizontal shafts only:

Multipoint (4-36)

Continuous Sweep (4-34)

Range extend (4-46)

Curve fit (4-45)

Trace (4-27)

Average (page 4-44)

Certain functions and options are available in both horizontal and

vertical alignment modes. Where necessary in this chapter, cross-

references are provided to the relevant sections of Chapter 4.

F

Note

Loading...

Loading...