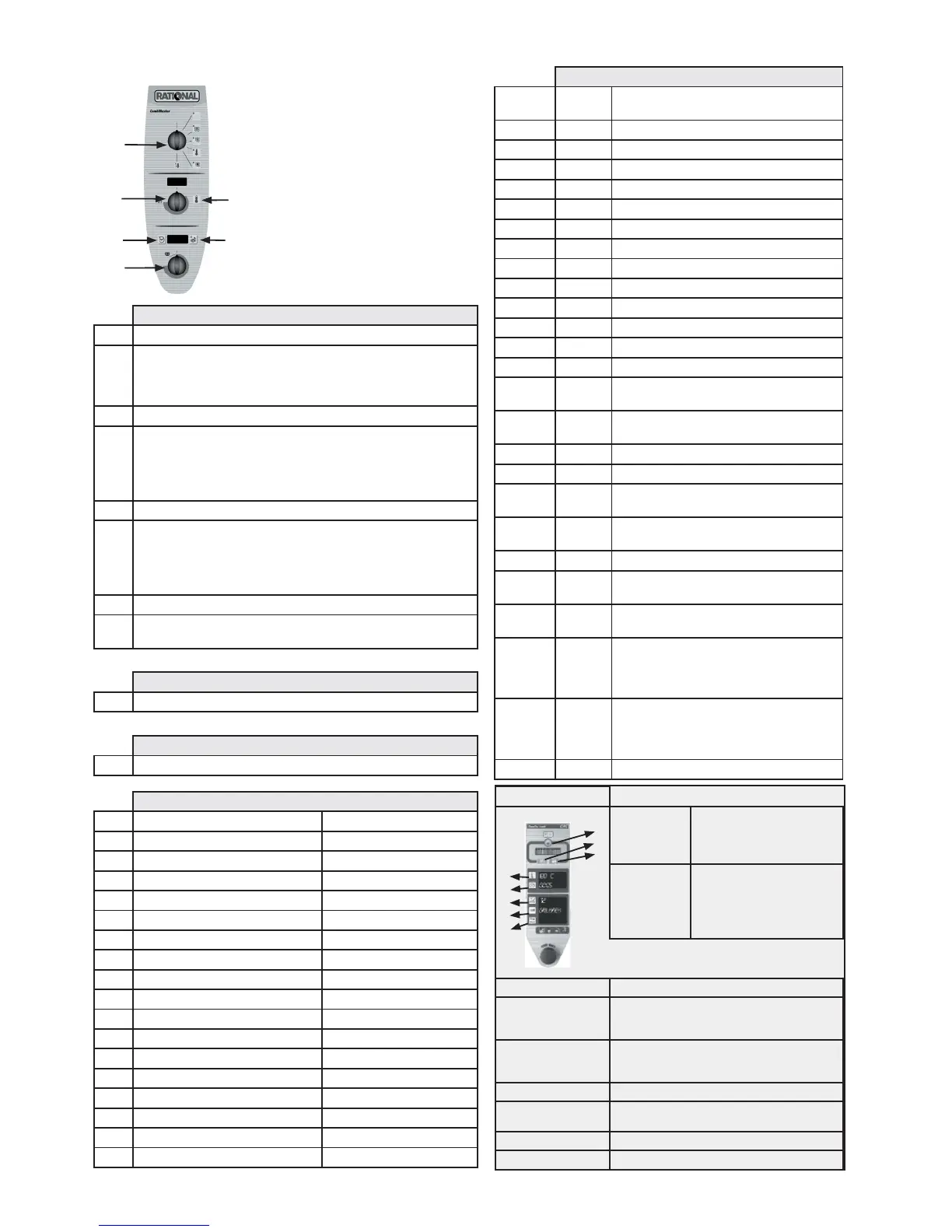

CM Service Reference

1

2 3

4 5

6

Key code CM (SCC line)

a: Cleaning program

select Cool Down with "1"

press key "5" for 10 sec.

„CLEn“ is shown in temperature display

press key "4" 1x;

b: De-scaling program

select Cool Down with "1"

press key "5" for 10 sec.

„CLEn“ is shown in temperature display

select "CALC“ with "6"

press key "4" 1x;

c: empty steam generator

select Cool Down with "1"

press key "5" for 10 sec.

„CLEn“ is shown in temperature display

select "SC“ with "6"

press key "4" 1x;

d: select °C - °F

select any cooking mode

press key "4" and "5" for 10 seconds

Enter Service level (Diagnostic, Settings, Running times)

Set dip switch 1 on pcb to "1" position

Enter function test

Set dip switch 3 on pcb to "1" position

Error code

Cabinet

display

Time

display

H20 OPEn open water tap

CHnG PoL change polarity of mains supply

E1 External EEPROM data error

E2 heating blocked by energy optimising

E3 B1 cabinet sensor defective

E4 B2 quenching sensor defective

E5 B3 core probe sensor defective

E6 B5 steam generator sensor defective

E7 Thermo sensor on pcb defective

E8 potentiometer cabinet temp. defective

E9 potentiometer time / core probe defective

E10 External EEPROM defective

E11 mode switch defective

E12 1Co

1St

fan motor bottom Bus error (LED shows?)

fan motor bottom defective

E12 2Co

2St

fan motor top Bus error (LED shows?)

fan motor top defective

E13 M4 SC-pump defective or blocked

E14 fi lling solenoid defective / sieve blocked

E15 pcb temp. above >85°C (185°F),

change air fi lter

E16 B5 steam generator sensor above

180°C (356°F), de-scale steam generator

E17 B5 steam gen. sensor below -5°C (23°F)

E18 B1 cab. sensor above 340°C (640°F)

(SSR?)

E20 1

2

Ignition box top bus error

Ignition box top bus error

E21 1xx

2xx

3xx

1xx - Steam,

2xx - Hot air top

3xx - Hot air bottom

Ignition box defective - change box

E22 1xx

2xx

3xx

1xx - Steam,

2xx - Hot air top

3xx - Hot air bottom

Ignition electrode, Ignition box, cable

E24 fl ash new software fi rst

Diagnostic program

dP1 Software version

dP2 B1 cabinet sensor

dP3 B3 core probe sensor

dP4 B2 quenching sensor

dP5 B5 sensor steam generator

dP6 PCB temperature must be below 75°C (167°F)

dP7 S3 door contact o - open; 1 - closed

dP8 S2 level electrode 0 - no water; 1 - ok

dP9 steam element energised 0 ; 1=50%; 2=100%

dP10 hot air element energised 0 ; 1=50%; 2=100%

dP11 rpm fan motor top

dP12 rpm fan motor botttom

dP13 Sicotronic energy optimising

dP14

dP15 Unit type and size

dP16 Gas - Flame current steam normal: 4,5 - 5,5µA

dP17 Gas - Flame current hot air top normal: 4,5 - 5,5µA

dP18 Gas - Flame current hot air bottom normal: 4,5 - 5,5µA

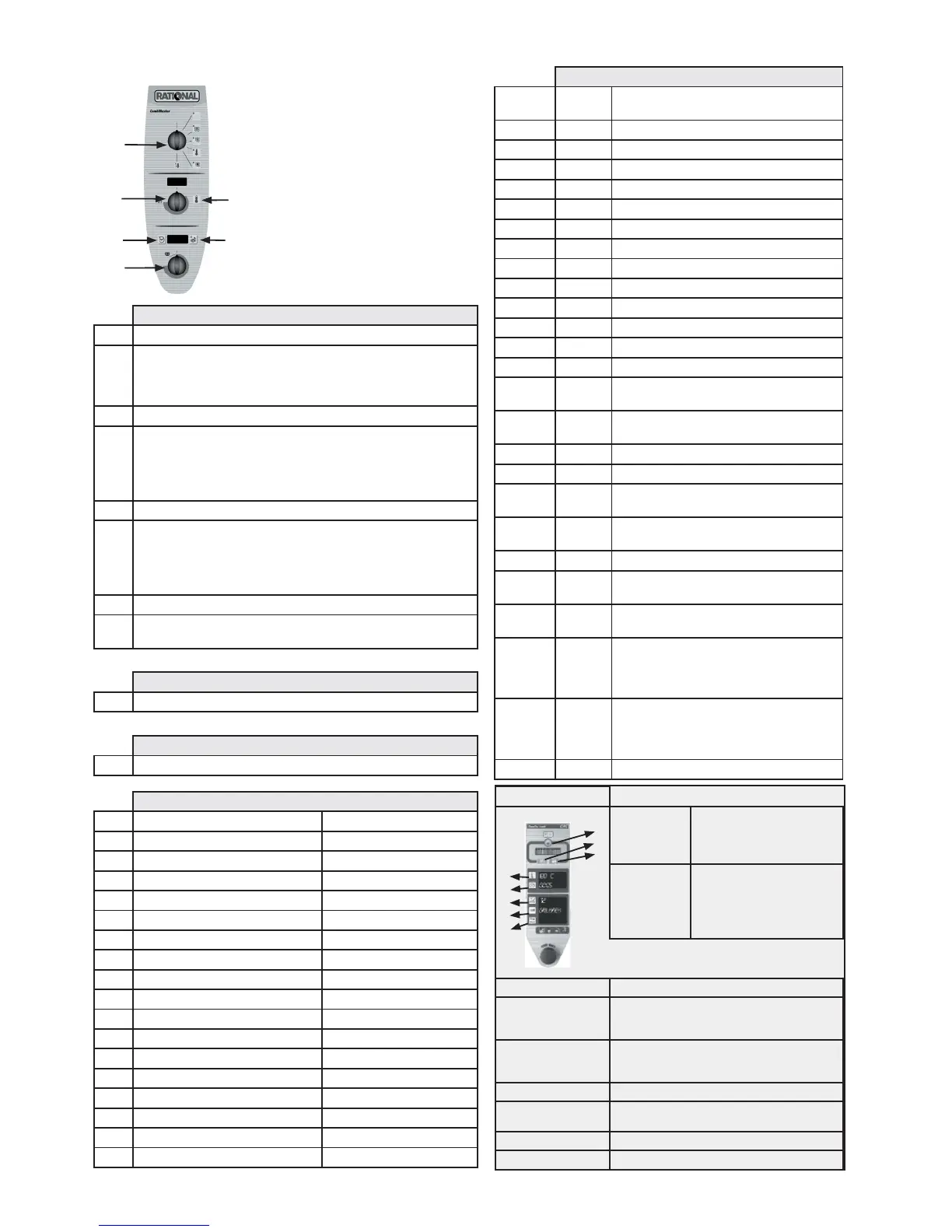

CPC - Help

a

b

c

Total reset1: press key "3"+"4"+"5" and

switch off at the same time

(erases all customer programs)

1

2

3

4

5

Total reset 2:

(memory reset)

activate Program lock fi rst;

press key "a"+"b"+"c"

and switch off at the same time;

(erases all customer programs)

humidity calibration is needed

Diagnostic mode: select any mode; press 4 sec. keys: "1"+"3"+"4"

Function test: select last position in diagnostic mode,

press key "5" and select at same time 11:11 in

time display, release key "5" and press it again

Abort CleanJet insert CleanJet arm , press keys: "1"+"2"+"3"

until display: X-*-* shows; press key "4" 10 se-

conds unitl display "CleanJet Aktive"

Service 1 Steam generator pump without function / blocked

Service 5, 6 insert CJ arm, open and close door; press keys

"1"+"2"+"4"

Calccheck1 check level electrode and water leakage

Calccheck 2,3,4 check level electrode, CDS sensor, CDS relais

Loading...

Loading...