-25-

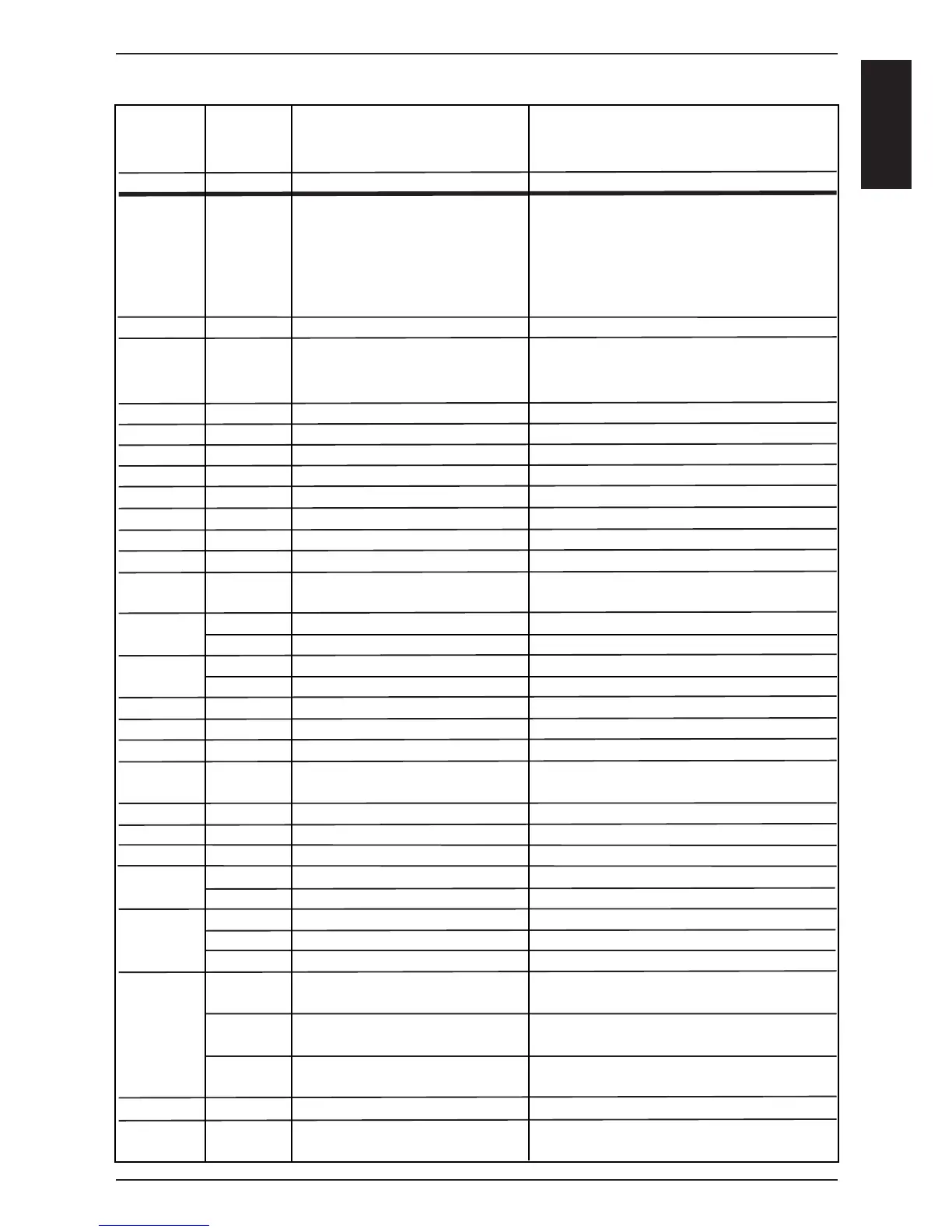

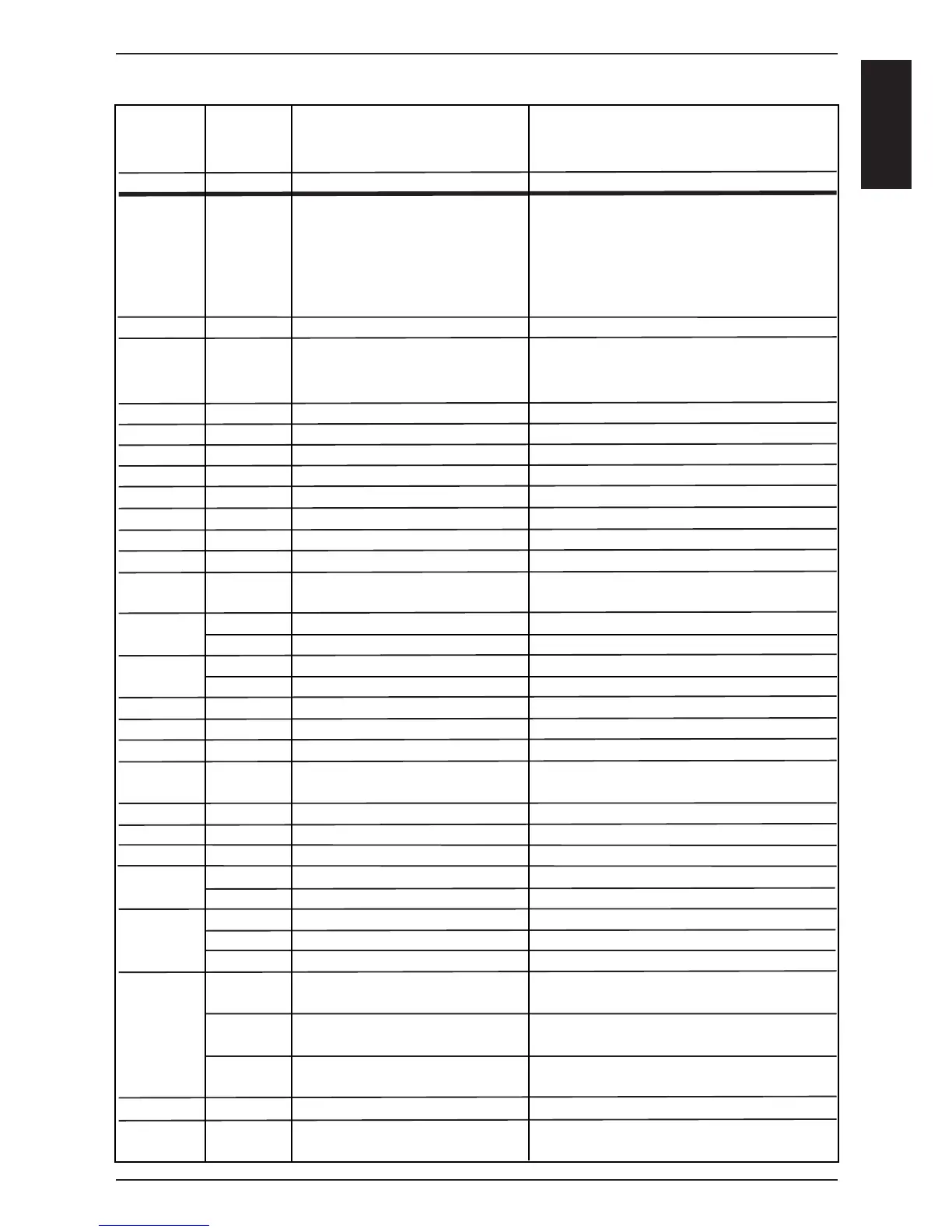

S

C

M

Int. cab.

display

H2o

CHnG

Timer

display

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E 12

E13

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E24

Timer

display

OPEn

PoL

Int. cab.

display

(E -press

core temp.

key)

1 St

1 Co

2 St

2 Co

1_

2_

1xx

2xx

3xx

1xx

2xx

3xx

Failure explanation

H2O open

Change Polarity

Part concerned

external EEPROM

Timeout of external

power optimising system

(Sicotronic)

B1 Interior cabinet sensor

B2 Quenching sensor

B3 Core sensor

B5 Sensor steam generator

Thermocouple on PCB

Poti interior cabinet

Poti timer/core temperature

External EEPROM

Mode switch

Fan motor 1 (bottom)

Fan motor 1 (bottom)

Fan motor 2 (top)

Fan motor 2 (top)

M4 SC-pump

Solenoid valve fi lling Y1

PCB temperature

Steam generator

Steam generator

Interior cabinet temp.

free

Ignition box 1

Ignition box 2

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

Ignition box 1 Steam

Ignition box 1 Hot air

Ignition box 2 Hot air

free

EEPROM

Description

Lack of water / open water tap

Phase / Neutral (only gas units)

Description

Not initialised

Heating blocked by the extern. energy-

optimising system for longer 2 min.

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Sensor broken

Defective

Defective

Defective

After 5 sec switching on the unit, a

cooking mode couldn‘t be identifi ed

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

St = Status (probably Motor defect)

Co = Communication,(Bus failure)

Mal function

Mal function

above 85°C (185°F)

Temperature B5 above

180°C (356°F)

Temperature B5 below -5°C (23°F)

Temperature B1 above 340°C (644°F)

Ignition box does not reply, Bus failure

Ignition box does not reply, Bus failure

Ignition box defective (change box)

Ignition box defective (change box)

Ignition box defective (change box)

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Testing of ignition and monitoring

necessary

Actual data structure of the EEPROM

does not match with the software; flash

pcb first

Failure Codes CM from 04-2004

Loading...

Loading...