SCC Service Reference

125 - activated

3

4 6

578

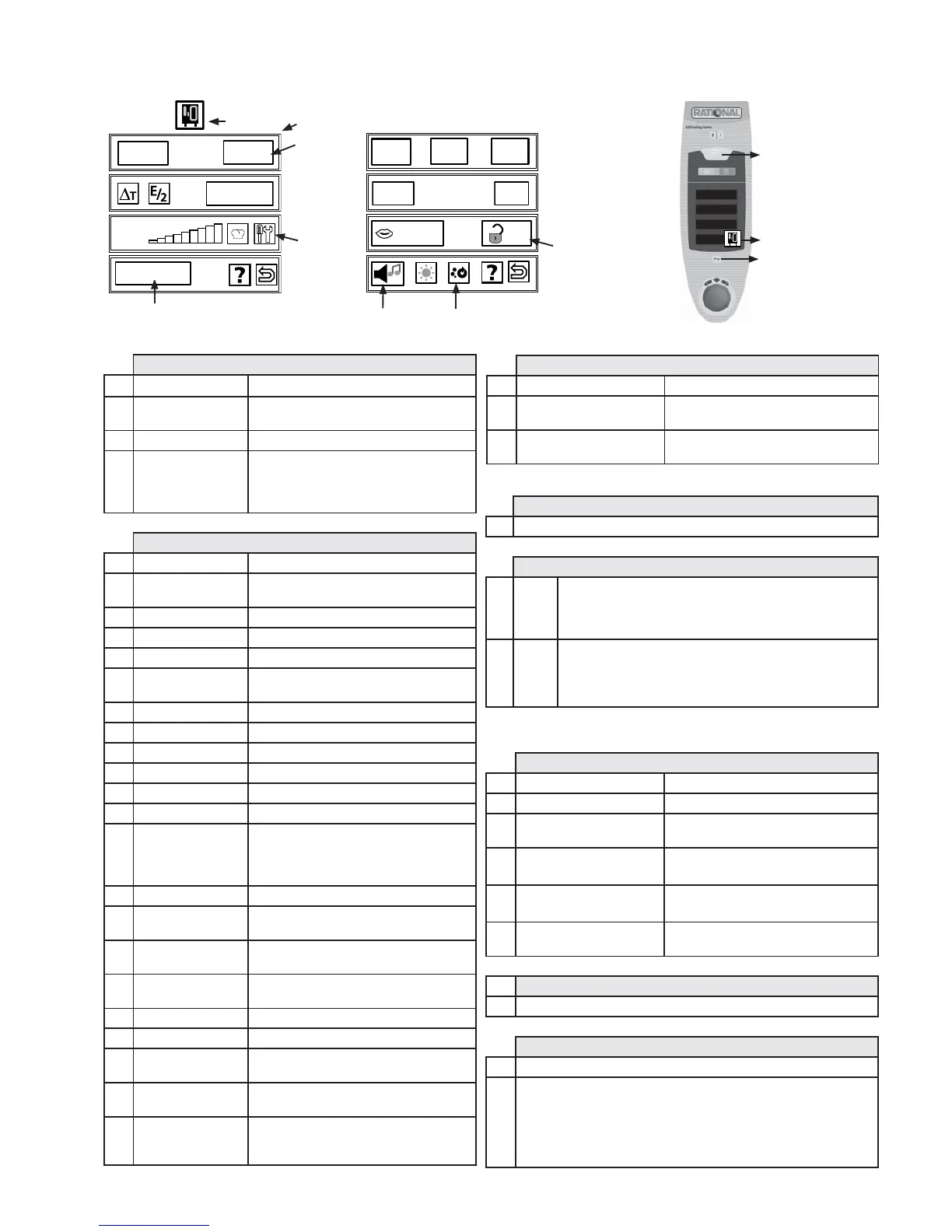

Operating buttons

1 Function key

2 Display SCC

Functions

3 HACCP Protocol - Download

4 Service key - de-scaling

- empty steam generator (with door open)

- Display type / software

- Download Diagnostic (since 01-07-09)

Service error code:

Service 10 SC-Pump without Function

Service 11 level electrode (Osmosis water) or check

valve above steam generator for leakage

Service 12 CDS sensor no output signal

Service 13 change level electrode

Service 14 Level electrode (Osmosis water)

Service 16 since 01-07-09,

fl ash new software version fi rst

Service 17 external EEPROM faulty

Service 20 thermocouple B1 faulty

Service 21 micro switch clima control faulty

Service 22

Service 23 SSR steam short circuit

Service 24 SSR hot air short circuit

Service 25 CleanJet water circulation faulty

- water doesn‘t hit fan wheel

- check pump, foreign bodies in water

pipe, racks / trolley must be inside cabinet

Service 26 drain valve closed

Service 27 drain valve doesn‘t close,

CleanJet without function

Service 28 B5 in steam generator above 180°C

(356°F), de-scale steam generator

Service 29 pcb temperature too high

(above 85°C / 185°F); change air fi lter

Service 30 humidity control faulty

Service 31.X core probe faulty

Service 32.X ignition box faulty, change ignition box

0-top; 1-bottom; 2-both

Service 33.X 4x Reset without function,

change ignition box; 1-top; 2-bottom

Service 34.X BUS signal error

1-I/O pcb, 2-motor bottom; 4-motor top;

8-ignition box top; 16-ignition box bottom

CDS

CleanJet

HACCP

Startzeit

Einstellungen

10:24

deutsch

am/pm

24 h

h:m

m:s

08/22/03

22.08.03

°C / °F

Prog

Gas-settings - values

Dyn. pressure LPG 27-57 mbar; 2,7-5,7 kPa

Dyn. pressure natural gas 18-25 mbar; 1,8-2,5 kPa

CO

2

max LPG

(G30) 3BP

10,4% +/- 0,2% for type 61-202

CO

2

max LPG

(G31) 3P

11,1% +/- 0,2% for type 61-202

CO

2

max natural gas H

(G20)

9,4% +/- 0,2% for type 61-201

9,5% +/- 0,2% for type 202

CO

2

max natural gas L

(G25)

9,3% +/- 0,2% for type 61-201

9,4% +/- 0,2% for type 202

Abort CleanJet

switch unit off and on again

Abort de-scaling program

before fi lling de-scaling liquid - use "BACK" arrow

after fi lling de-scaler into steam generator

- switch unit off and on again

- press ABORT key - remaining time will be adjusted automatically

- switch unit off and on again

- press ABORT key - time will be adjusted automatically 2x

- use steam mode for 15 min. and rinse interior cabinet

Enter Service level

set dip switch "1" on pcb to ON position

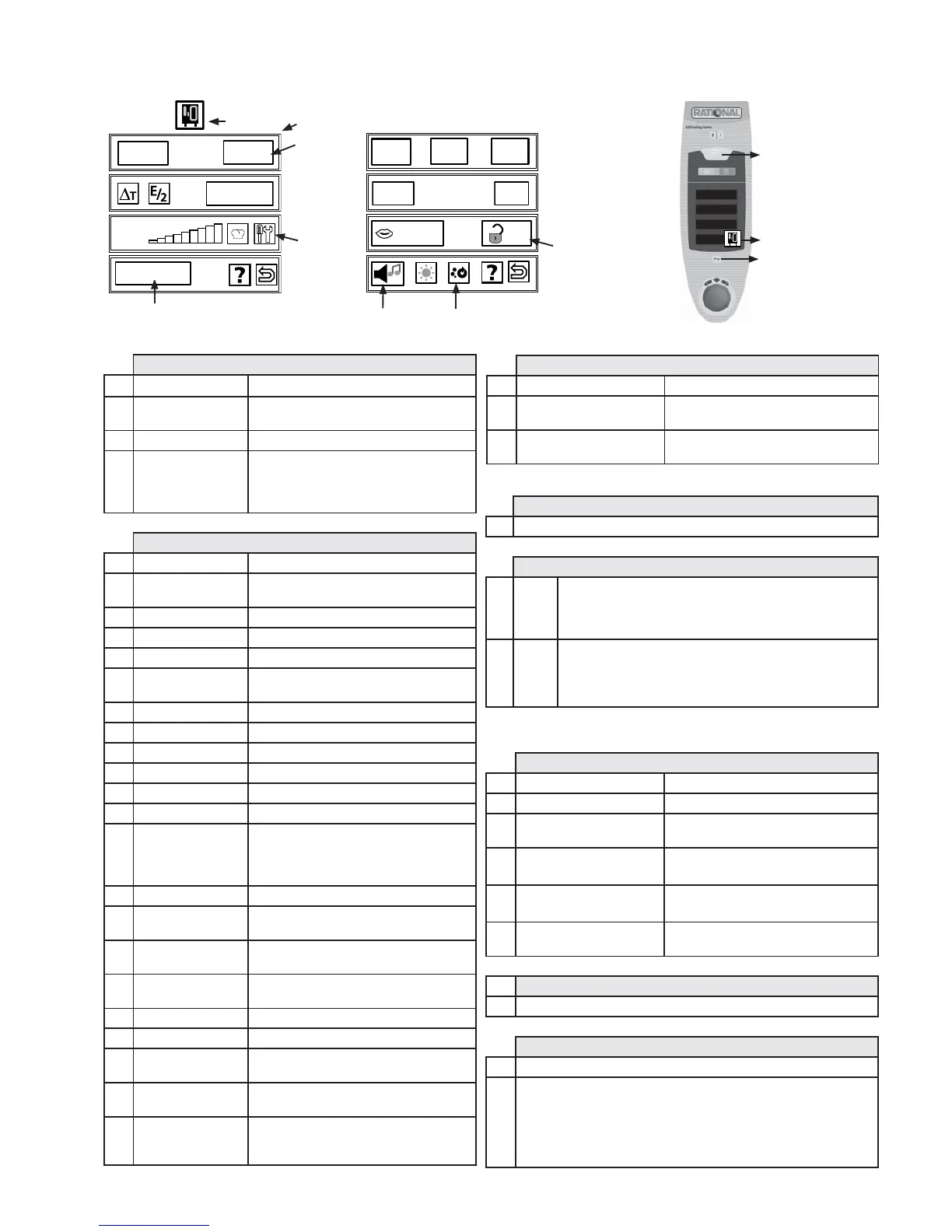

Show Mode - switch off or on

ON press function key "a" followed by program key "b" and

SCC key "c" for 10 seconds until -

acoustic signal - Beep

and door handle in icon function key "a" shows in red

OFF press function key "a" followed by program key "b" and

SCC key "c" for 10 seconds until -

acoustic signal - Beep

and door handle in icon function key "a" shows in blue

c

a

b

Settings

english

User settings (5)

6 Program Lock Password: 12345; TTREU

7 Buzzer

Loudness and duration

duration setting since 01-07-09

8 CleanJet

reminder

Active, when symbol is red

Start time

Loading...

Loading...