-86-

S

S

C

C

Before you carry out a fl ue gas analysis

check input gas fl ow pressure when burner is running

• Switch on unit. Select any mode and cooking time.

Wait till burner works

• Check input gas fl ow pressure

• See correct values of input fl ow pressure on serial plate

• If necessary adjust gas input pressure

Select „Function Test“:

• Switch on unit

• Open front panel

• Set DIP switch 1 on PCB to „ON“ position

• Select „Function Test“

Select at „FunctionTest“ the position „Gas Steam Burner“

Press key and select „Max“ rpm,

if it‘s not already selected

Activate the burner with the „Start“ key.

Note: Start key is used as a switch and will automatically

deactivate after 4 minutes

Display 4 indicates the desired CO

2

value, e.g. 9,2%,

fl ame current, i.e. 5,2µA and the corresponding rpm of the

blower motor.

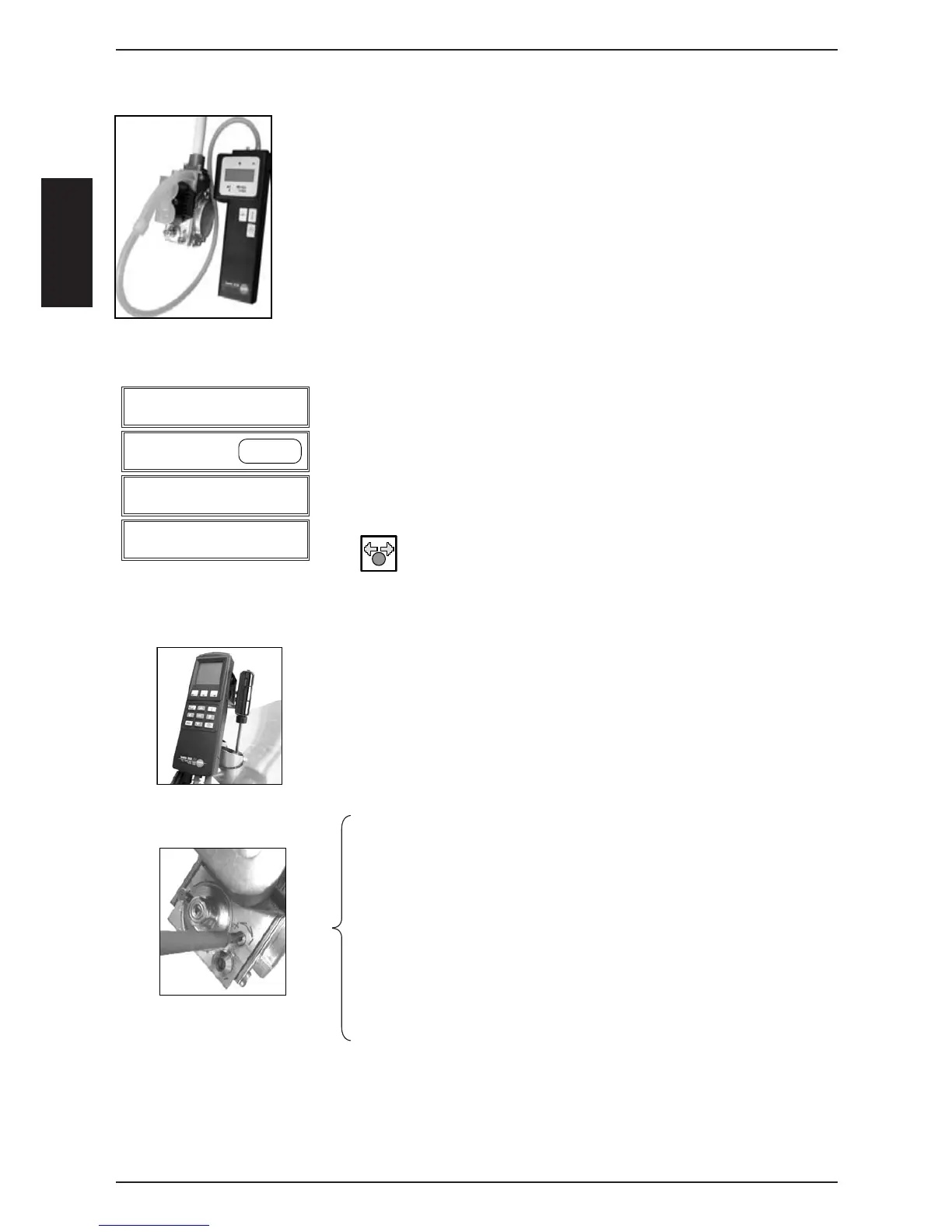

Place fl ue gas testing nozzle in correct fl ue outlet

„Adjust CO

2

to given value by turning CO

2

screw on gas valve.

You also can fi nd that value on table „Values for burner adjus-

tments“

• If CO

2

value is too low => turn CO

2

screw

anti clockwise (+ direction),

• If CO

2

value is too high => turn CO

2

screw

fi rst 2 turns clockwise (- direction), and than slowly

anti clockwise (+ direction) until you get the indicated CO

2

value. (Screw adjustment tolerance).

• CO value must be below 300ppm

Press „Stop“ key. Blower will stop.

Flue gas analysis: SCC gas from 04-2004

Loading...

Loading...